Page 31

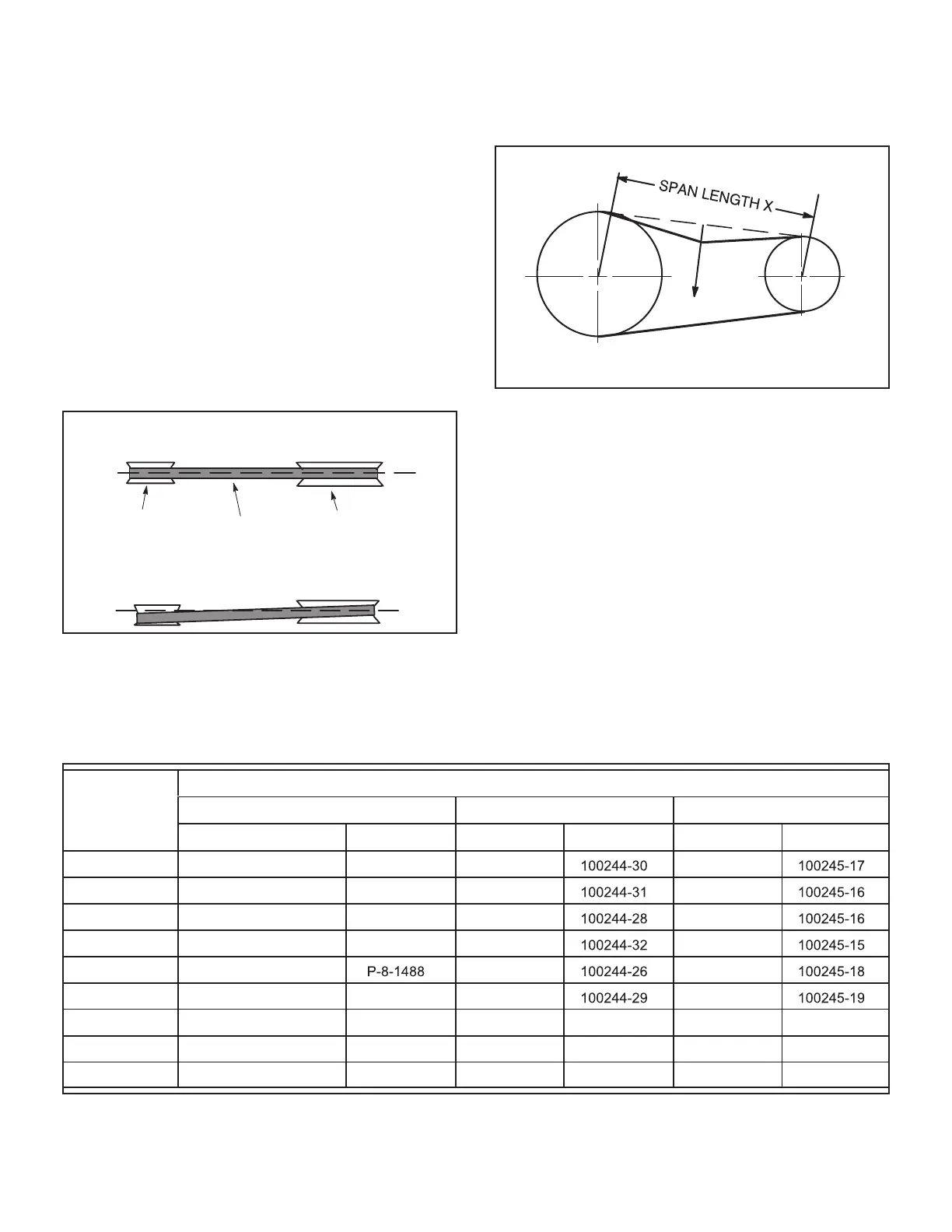

C-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

This will allow belt to stretch and seat grooves. Make sure

1 -

2 - To increase belt tension -

Slide blower motor downward to tighten the belt. This

increases the distance between the blower motor and

the blower housing.

3 - To loosen belt tension -

Slide blower motor upward to loosen the belt. This

decreases the distance between the blower motor

and the blower housing.

Tighten four bolts securing motor base to the

mounting frame.

PULLEY ALIGNMENT - NO TENSIONER

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

FIGURE 8

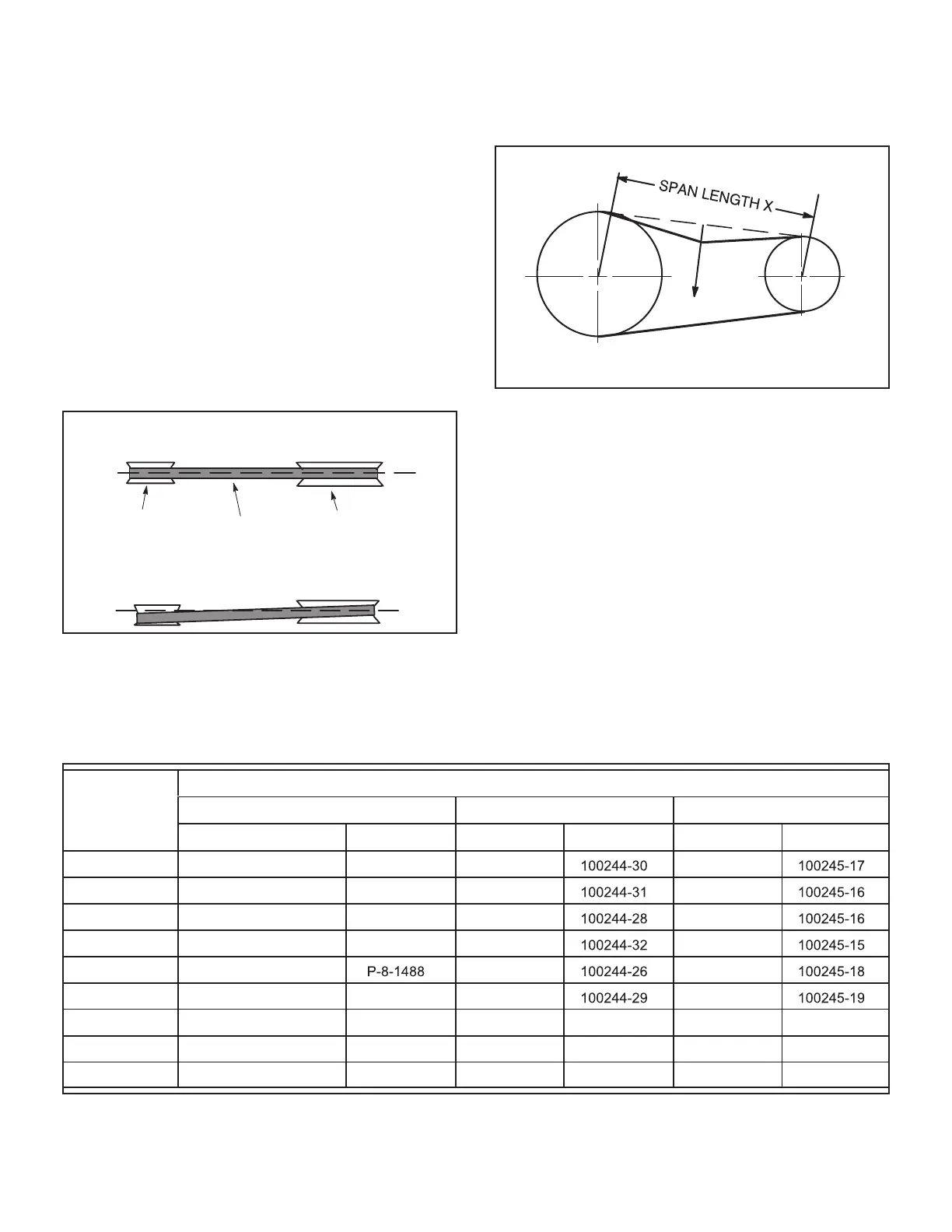

D-Check Belt Tension

Overtensioning belts shortens belt and bearing life. Check

1 -

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FORCE

FIGURE 9

2 -

3 -

5 -

A force below these values indicates an underten-

sioned belt. A force above these values indicates an

overtensioned belt.

F-Field-Furnished Blower Drives

component manufacturers numbers.

TABLE 6

Drive No.

DRIVE COMPONENT PART NUMBERS

Motor Pulley Blower Pulley Belts

Browning OEM Browning OEM Browning OEM

Z01 1VP34 X 7/8 31K6901 AK54 X 5/8 A40

Z02 1VP34 X 7/8 31K6901 AK46 X 5/8 A39

Z03 1VP34 X 7/8 31K6901 AK41 X 5/8 A39

Z04 1VP34 X 7/8 31K6901 AK39 X 5/8 A38

Z05 1VP44 X 7/8 AK49 X 5/8 A41

Z06 1VP50 X 7/8 53J1501 AK51 X 5/8 A42

ZAA02 1VP40 X 7/8 79J03 BK80H 100788-03 A53 100245-40

ZAA03 1VP40 X 7/8 79J03 AK59 X 1 31K68 A50 100245-29

ZAA04 1VP44 X 7/8 P-8-1488 AK59 X 1 31K68 AX51 13H01

Loading...

Loading...