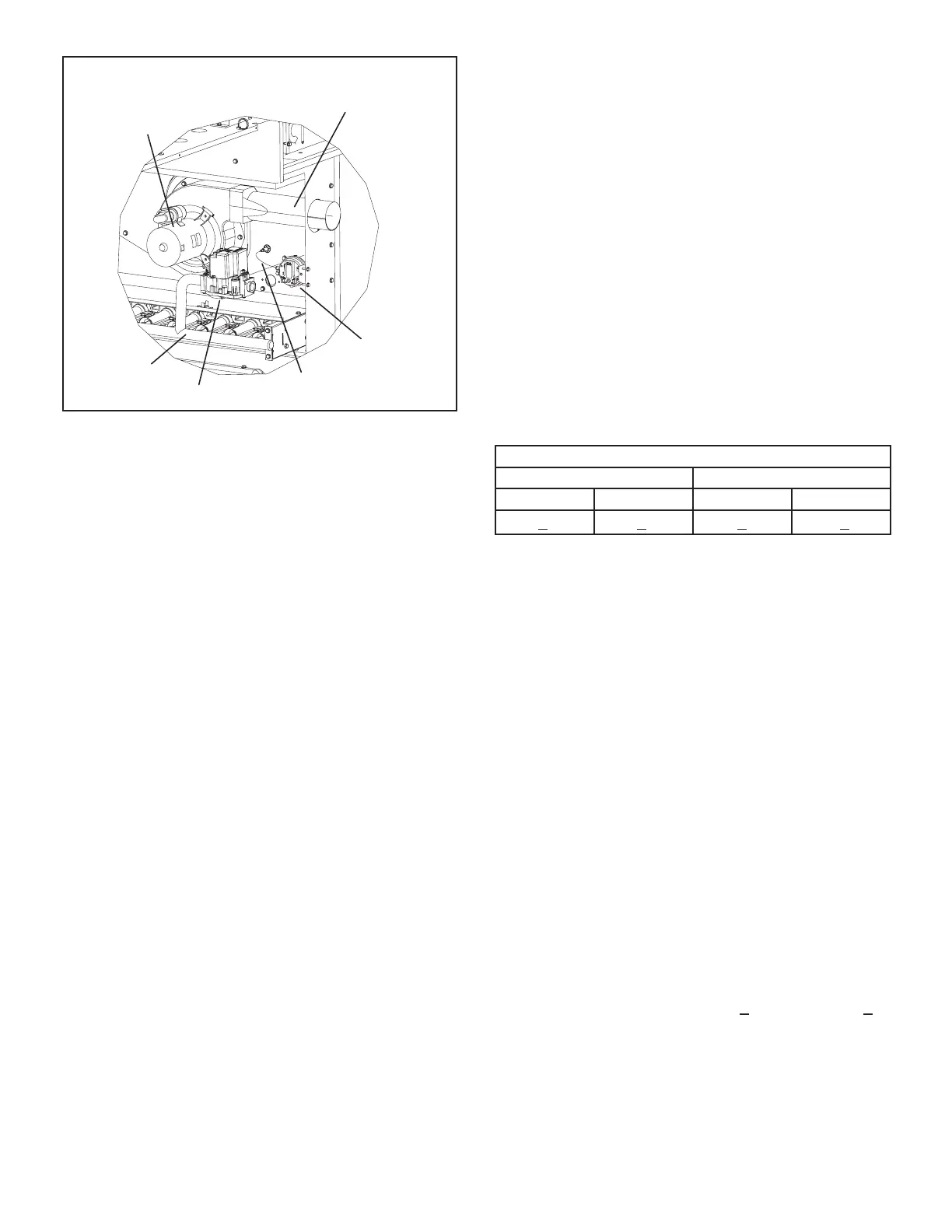

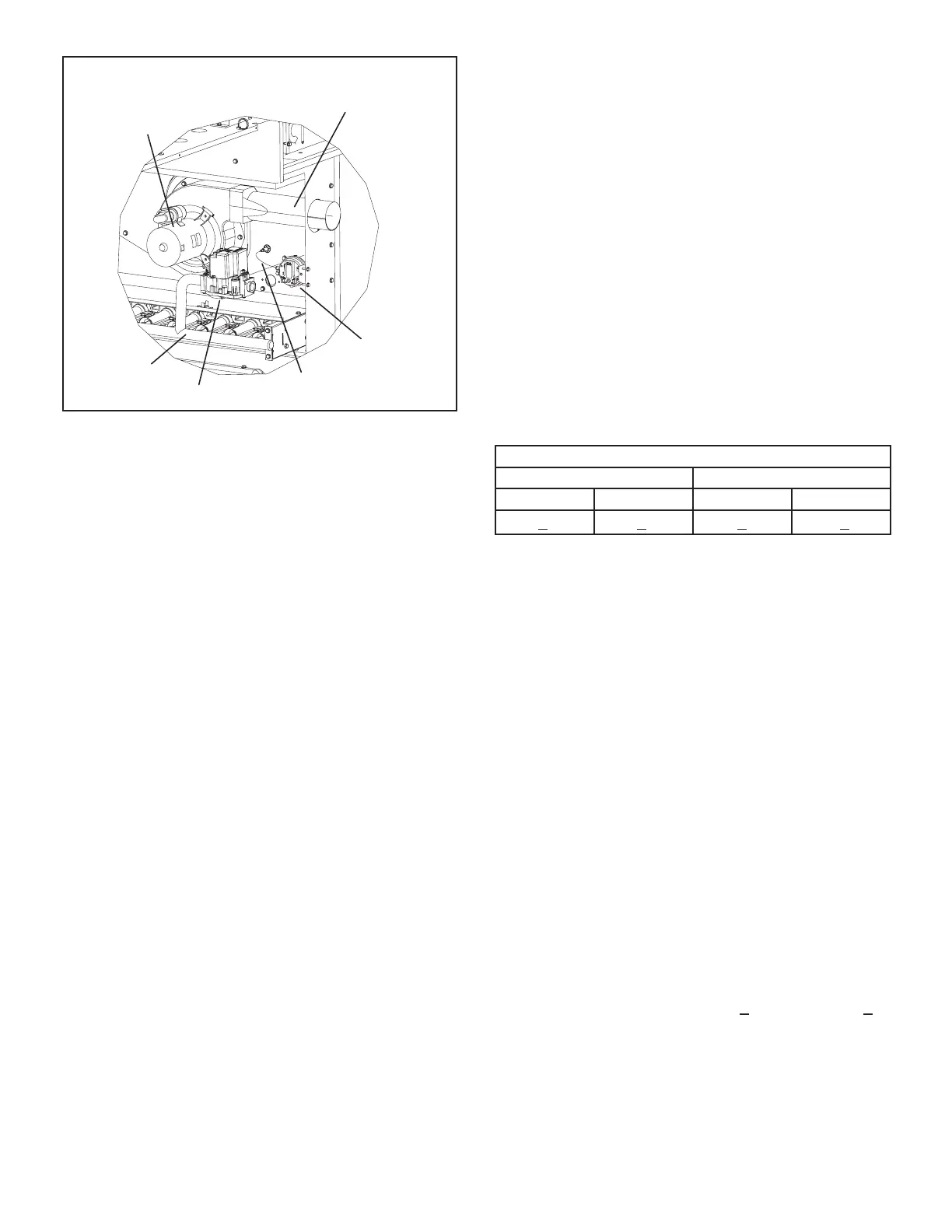

S18

Combustion Air

Prove Switch

Gas Valve

Gas

Manifold

Vent Connector

B6

Combustion

Air Inducer

Combustion Air

Prove Switch Tubing

FIGURE 11

6-Combustion Air Inducer B6

Combustion air inducers provide air to the corresponding

burners while clearing the combustion chamber of ex-

haust gases. The inducer begins operating immediately

upon receiving a thermostat demand and is de-energized

protection. Inducers are supplied by various manufactur-

electrical ratings can be found on the unit rating plate.

-

the combustion air inducer to vent exhaust gases from

-

the combustion air prove switch is closed and the delay is

-

sensed or at the end of the eight second trial for ignition.

-

start the inducer in high speed for second-stage heat

All combustion air inducer motors are sealed and cannot

be oiled. The inducer cannot be adjusted but can be re-

moved from the vestibule to clean the wheel.

7-Combustion Air Motor Capacitor C3

The combustion air inducer motors in all ZGB units require

run capacitors. Capacitor C3 is connected to combustion

-

bustion air motor nameplate.

8-Gas Valves GV1

Units are equipped with a single or two stage gas valve.

-

gized by the ignition control simultaneously with the spark

second stage operator is energized directly from A3. A

shows factory gas valve regulation pressures.

TABLE 7

Natural

High High

1.7 3.5

9-Spark Electrode (Ignitor) Figure 12

An electrode assembly is used for ignition spark. The elec-

trode is mounted through holes under the burner located

farthest to the right. The electrode tip protrudes into the

-

sembly is fastened to burner supports and can be removed

for service without removing any part of the burners.

burner to burner until all are lit.

The spark electrode is connected to the ignition control by

female quick connects on both ends of the wire.

NOTE - If electrode wire must be replaced, wire and sup-

pression must be same type cable. See www.davenet for

replacement.

The spark electrode assembly can be removed for inspec-

tion by removing the screw securing the electrode assem-

bly and sliding it out of unit.

and gapped correctly. Spark gap may be checked with

appropriately sized twist drills or feeler gauges. Discon-

nect power to the unit and remove electrode assembly.

Loading...

Loading...