5-Proper Gas Flow

Furnace should operate at least 5 minutes before check-

-

table 12. Seconds in table 12 are based on a 1 cu.ft. dial

time needed.

NOTE - To obtain accurate reading, shut o all other gas

appliances connected to meter.

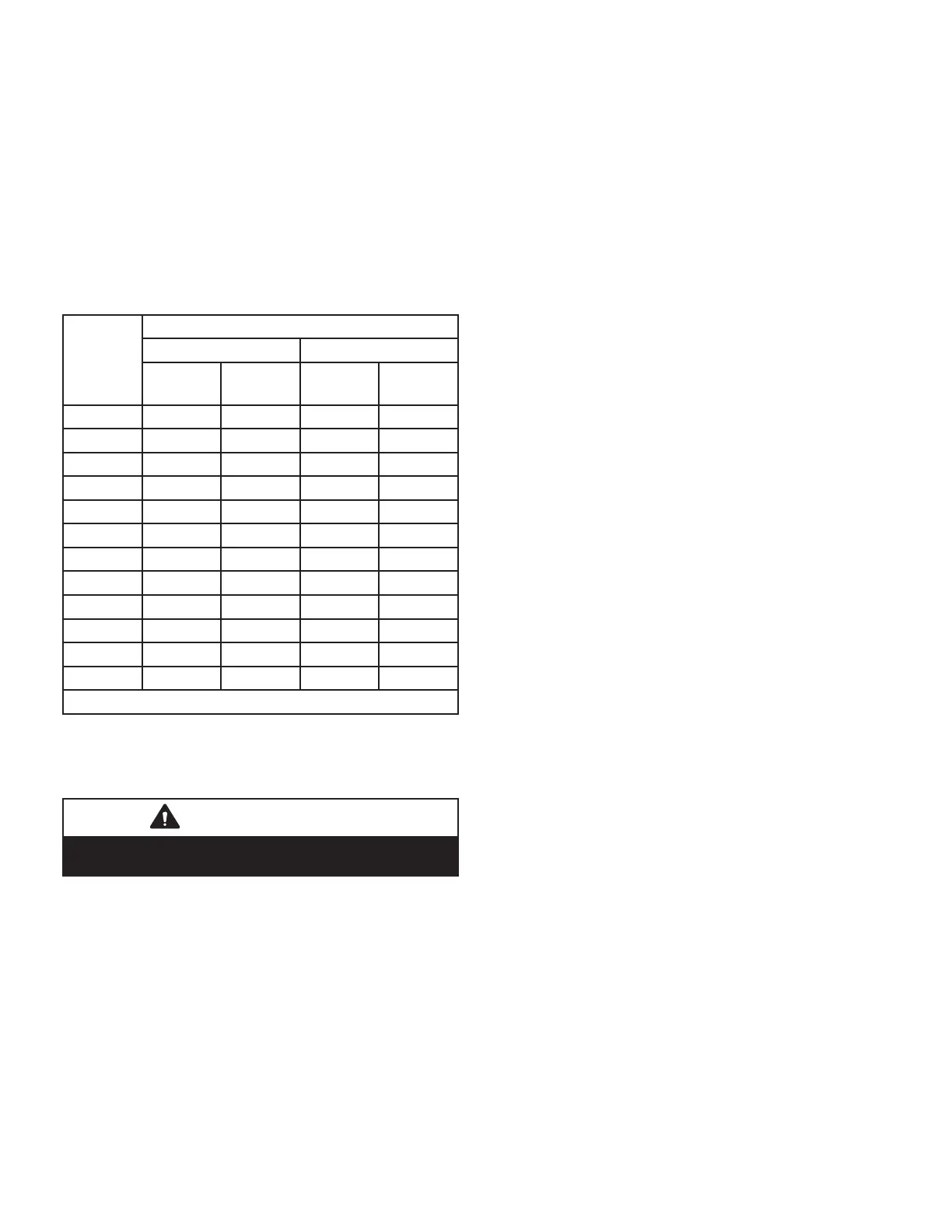

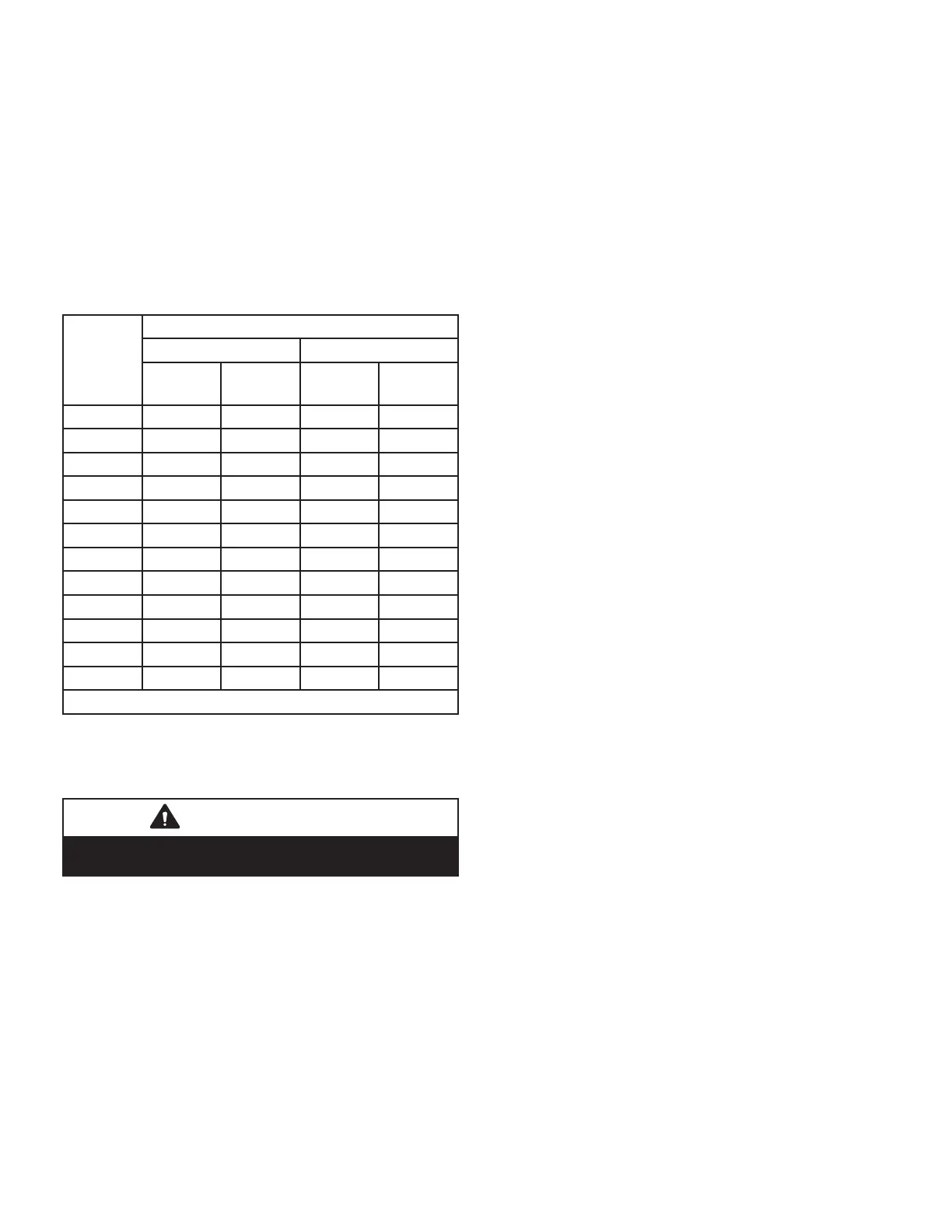

TABLE 12

GAS METER CLOCKING CHART

Unit Input

Natural

1 cu ft

dial

2 cu ft

dial

1 cu ft

dial

2 cu ft

dial

55 277

111 222

33

31

21 53

15 75

35

Note: Table assumes standard temperature (60°F), pres-

sure(30in.Hg.), and fuel heating values (Btuh/Ft.3). Apply

pressure corrections in altitudes above 2000 ft.

IMPORTANT

Disconnect heating demand as soon as an accurate

reading has been obtained.

6-Heat Exchanger

Visually inspect heat exchanger. If replacement is neces-

sary refer to the instruction provided with the replacement

kit.

7-Flame Sensing

Flame current is an electrical current which passes from

the ignition control through the sensor electrode during unit

operation. The current passes from the sensor through the

-

NOTE-Electrodes are not eld adjustable. Any alterations

to the electrode may create a hazardous condition that

can cause property or personal injury.

1 - Disconnect power to unit.

2 -

sensing electrode and the sensing lead.

3 -

demand.

5 - Disconnect power to unit before disconnecting

meter. Make sure sensor wire is securely

reconnected before reconnecting power to unit.

NOTE-If the meter scale reads 0, the leads are reversed.

Disconnect power and reconnect leads for proper polarity.

B-Cooling System Service Checks

ZGB units are factory charged and require no further ad-

-

NOTE-When unit is properly charged discharge and

suction pressures should approximate those in tables 8

through 11.

Loading...

Loading...