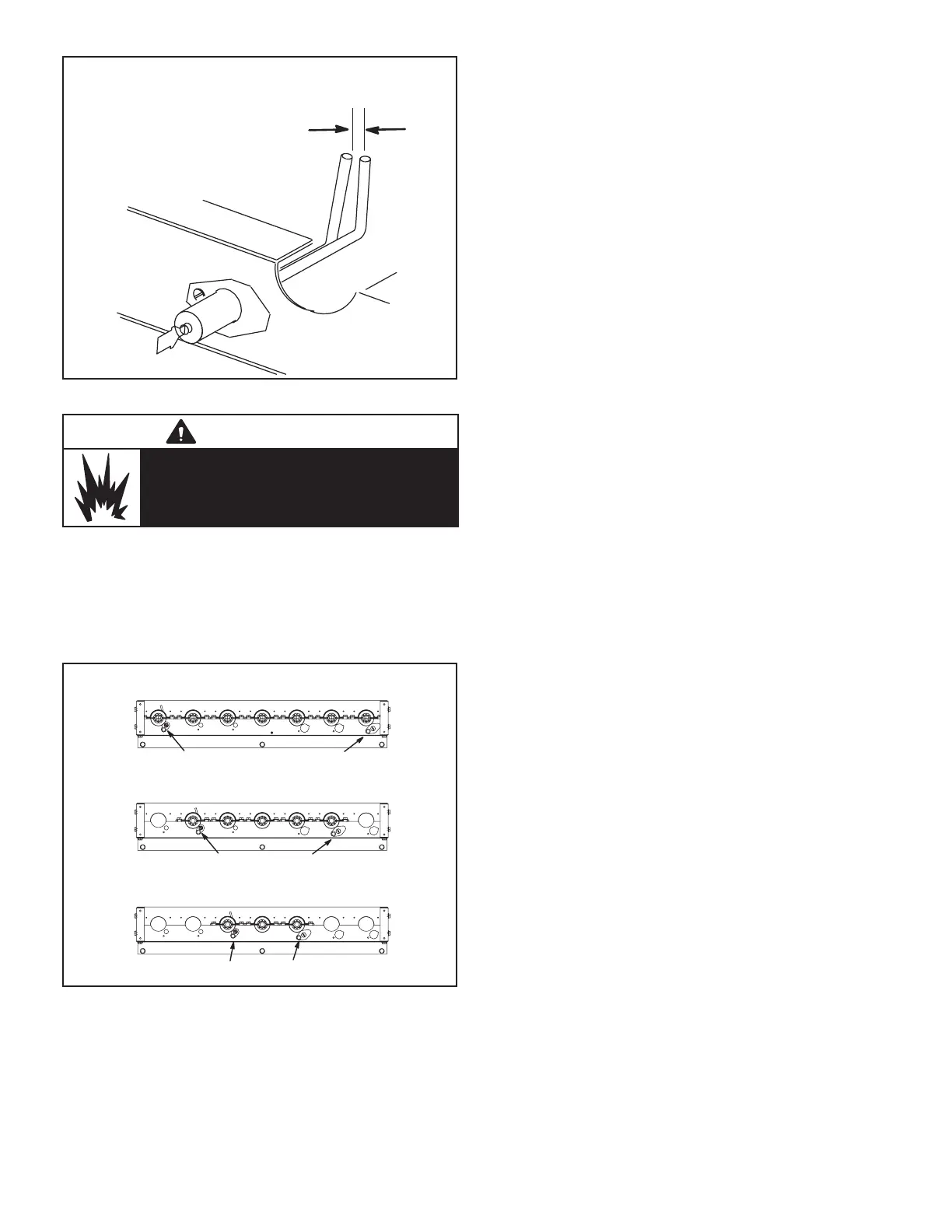

SPARK GAP

SHOULD BE 1/8”

(3mm)

FIGURE 19

WARNING

Danger of explosion. Can cause injury

or death. Do not overtighten main burner

mounting screws. Snug tighten only

7 -

lighting instructions attached to unit and use

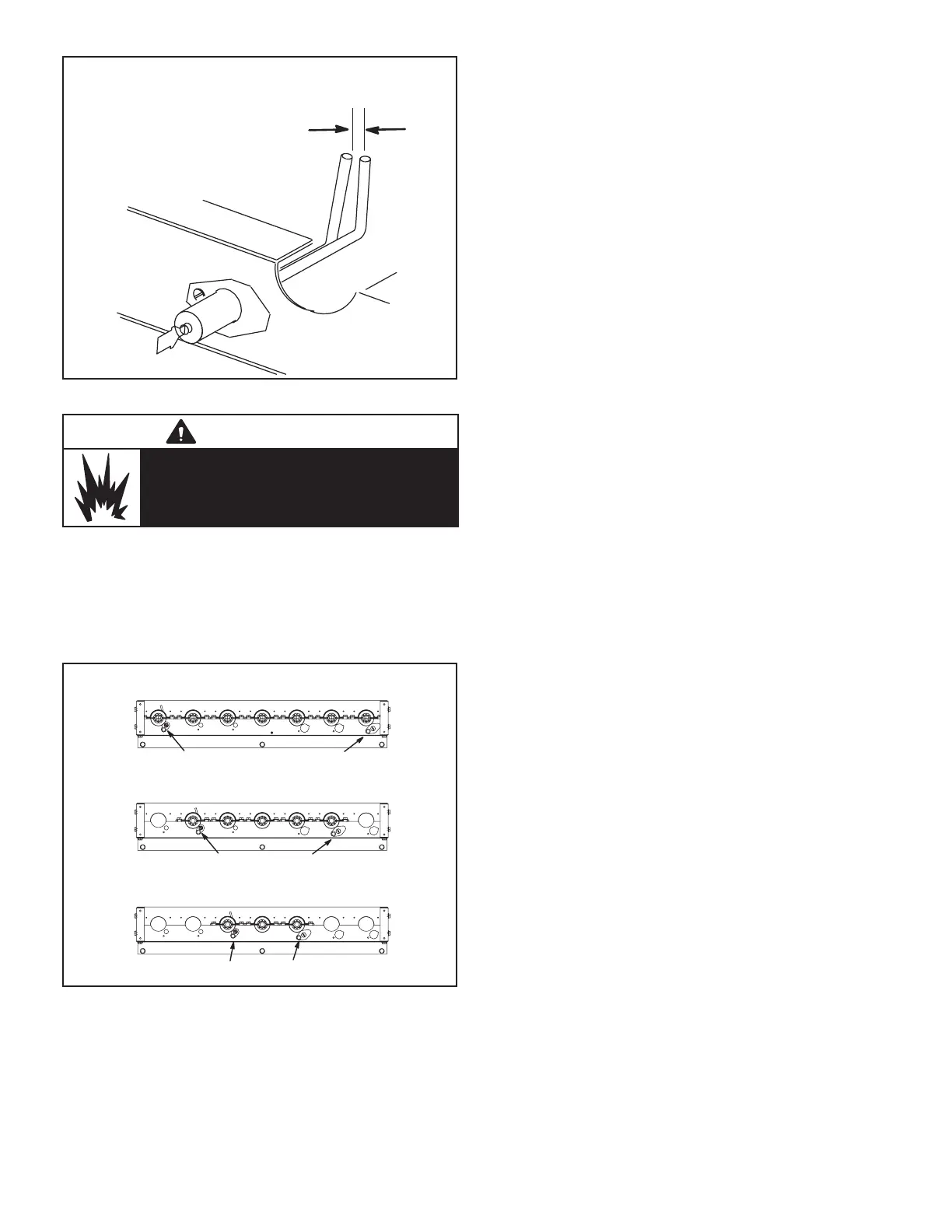

150,000 BTUH - 7 BURNERS

108,000 BTUH - 5 BURNERS

65,000 BTUH - 3 BURNERS

SENSOR IGNITOR

SENSOR IGNITOR

SENSOR IGNITOR

FIGURE 20

D-Combustion Air Inducer

A combustion air proving switch checks combustion air in-

ducer operation before allowing power to the gas control-

ler. Gas controller will not operate if inducer is obstructed.

inducer wheel should be checked and cleaned prior to

-

riodically during the heating season to establish an ideal

cleaning schedule.

1 -

2 -

of the outdoor section under the control box.

3 -

Clean inducer wheel blades with a small brush and

damage exposed fan blades. Clean accumulated

5 -

connector to original location and secure with

retained screws. It is recommended that gaskets be

replaced during reassembly.

7 - Clean combustion air inlet louvers on heat access

panel using a small brush.

E-Flue Passageway and Flue Box

-

-

tightly sealed.

F-Evaporator Coil

Inspect and clean coil at beginning of each cooling season.

Clean using mild detergent or commercial coil cleanser.

Flush coil and condensate drain with water taking care not

G-Condenser Coil

Clean condenser coil annually with water and inspect

monthly during the cooling season.

Note - Do not use commercial coil cleaner on the all alu-

minum coil. Using anything other than water could result

in corrosion and/or leaks.

Clean the all-aluminum coil by spraying the coil steadily

from the coil face. Take care not to fracture the braze be-

work cautiously to prevent damage.

H-Supply Blower Wheel

Annually inspect supply air blower wheel for accumulated

access panel or to clean blower wheel.

Loading...

Loading...