Transport

•

Ensure appropriate handling.

•

Make sure that all component parts are securely mounted. Secure or remove loose

component parts.

•

Only use safely xed transport aids (e.g., eye bolts or support plates).

•

Do not damage any components during transport.

•

Avoid electrostac discharges on electronic components and contacts.

•

Avoid impacts.

•

Check the carrying capacity of the hoists and load handling devices. The weights can be

found in the shipping documents.

•

Secure the load against pping and falling down.

•

Standing beneath suspended loads is prohibited.

The transport weights can be found in the shipping documents!

The motors mounted on the gearbox are somemes equipped with ears. These

are exclusively intended for mounng the motor on/removing the motor from

the gearbox and must not be used for the complete geared motor!

CAUTION!

Danger from pping or falling loads!

Standing beneath suspended loads is prohibited!

▶

Use addional appropriate liing aids, if required, to achieve a direcon of loading which is

as vercal as possible (highest load carrying capacity). Secure liing aids against shiing!

▶

Screw in the transport aids completely. They must have even and full-surface contact!

▶

Transport aids must be loaded vercally in the direcon of the screw axis! Diagonal or

lateral tension reduces the load carrying capacity! Observe data in standard DIN 580!

The thread in the output sha can be used with smaller drives. Larger gearboxes have a

transport thread for eye bolts in accordance with DIN 580 in the gearbox housing as standard.

The eye bolt is not included in the scope of supply!

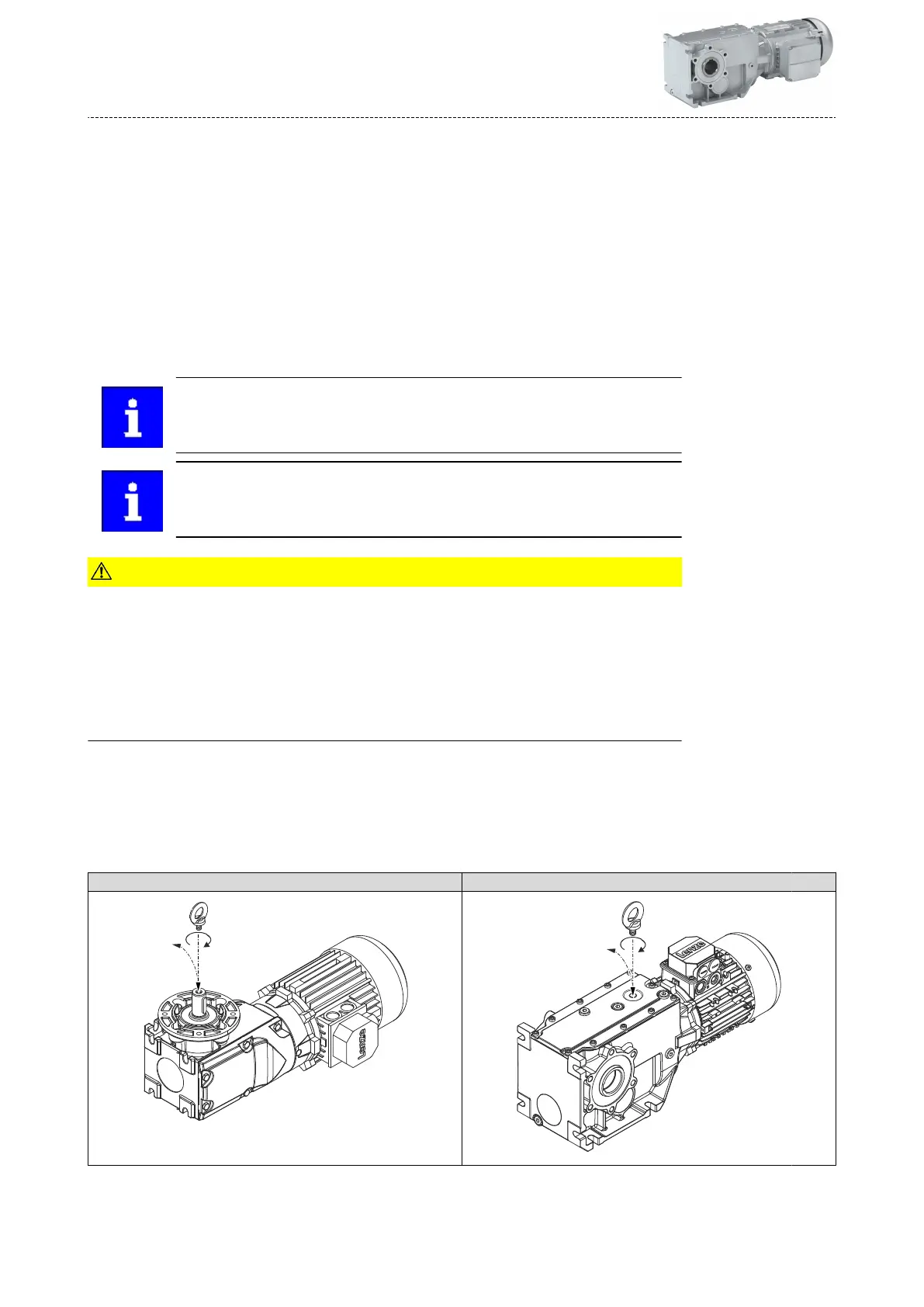

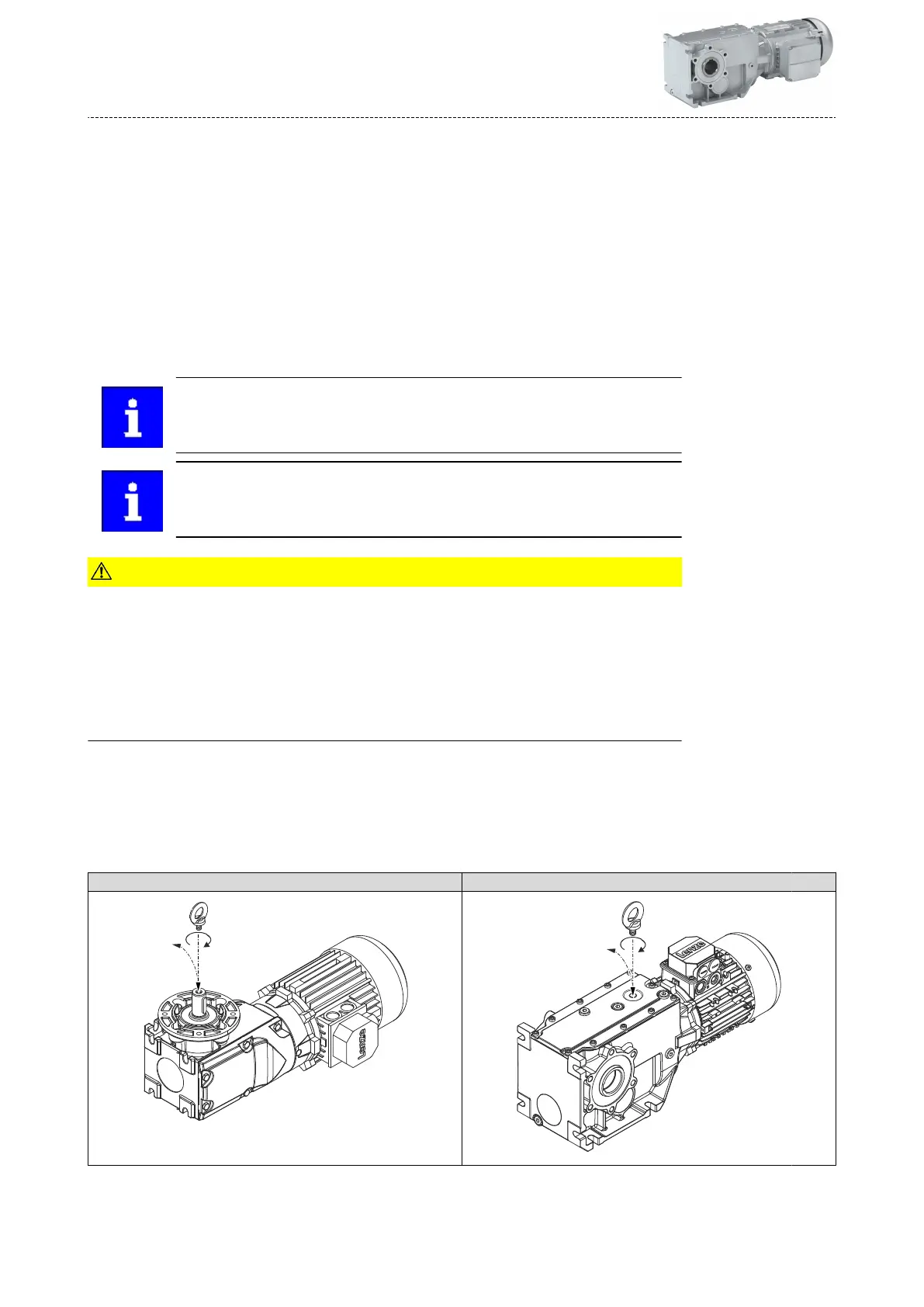

The posion of the transport thread can be seen in the following representaons.

Posion of the eye bolt

G50AB045...G50BB124 from G50BB145

Mechanical installaon

Transport

20

Loading...

Loading...