52

PARAMETER-SETTING MANUAL

VARMECA 30

Variable speed motors and geared motors

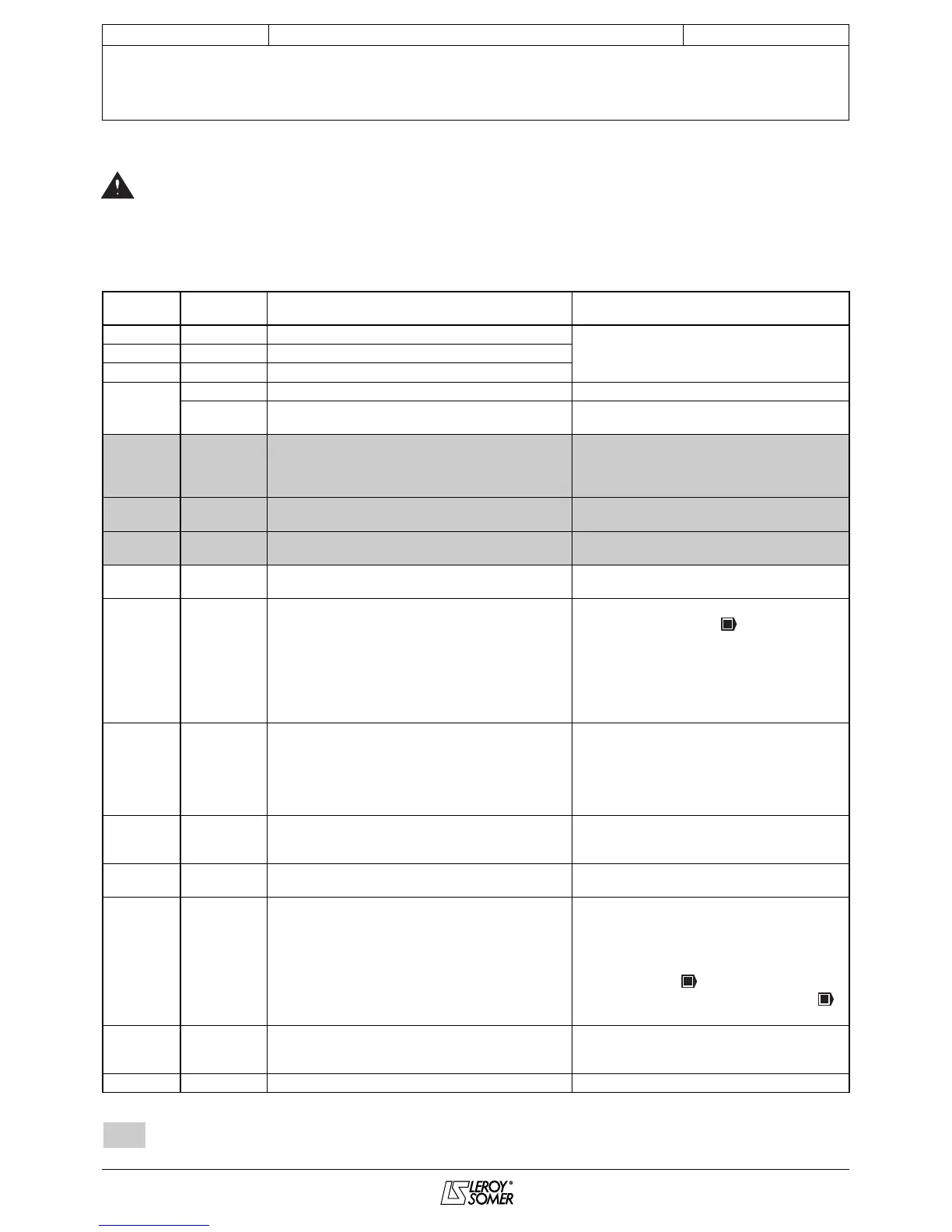

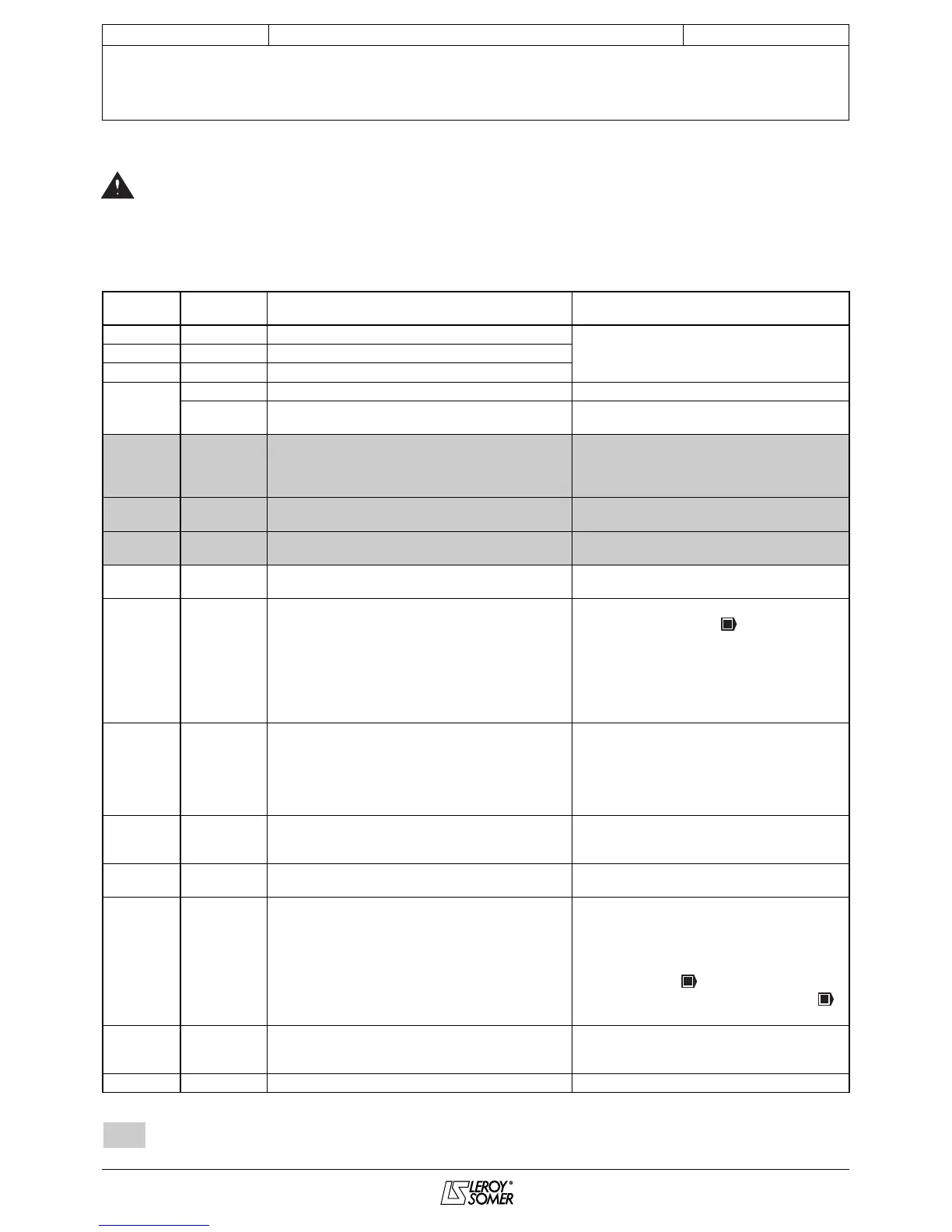

SWITCHING TO PROTECTIVE MODE – DIAGNOSTICS

LEROY-SOMER

3847 en - 2013.06 / i

• The user must not attempt to repair the drive,

or perform any diagnostics other than those listed

in this section. If the drive malfunctions, it should be

returned to LEROY-SOMER via your usual contact.

The LCD KEYPAD or PAD VMA options give a certain amount

of information which simplifies the diagnostic process.

This information is broken down into 2 categories:

– Information concerning operation

– Fault tripping

If the drive switches to protection mode, the drive output

bridge is inactive, and the drive no longer controls the motor.

The display indicates "triP" and the fault code alternately.

All the faults indicated by the display unit are listed in the

following table in alphabetical order.

: Faults specific to the VMA 33/34

PAD

VMA30

LCD

KEYPAD

Cause Solution

cL1 4 mA ADI1 Loss of the current reference on analogue input ADI1

• Check the connections of analogue input

ADI1, ADI2 or ADI03

• Check that the reference is > 3 mA

cL2 4 mA ADI2 Loss of the current reference on analogue input ADI2

cL3 4 mA ADIO3 Loss of the current reference on analogue input ADIO3

EEF

The drive rating does not correspond to XPress Key

EEPROM EEPROM fault

• Perform a return to factory settings procedure

(see 65)

EnC1

Chann. U

encod.

Loss of channel U

• Check the connection and supply voltage of

the encoder

• Check the speed feedback

• Replace the encoder

EnC2

Chann. V

encod.

Loss of channel V • Check the encoder voltage and connections

EnC3

Chann. W

encod.

Loss of channel W • Check the encoder voltage and connections

Fbus Bus loss Disconnection of the fieldbus during operation

• Check the connections

• Check the fixing of the fieldbus option

It.AC

I

2

t motor Motor overload I

2

t

• Check that the motor is not overloaded

• Adjust the rated speed ( )

• Check that the motor rated current is set

correctly (06)

• Speed feedback: Check the coupling, and

check that the signal is not subject to

interference

• Check the number of motor poles in 62

It.br Brake resist.

Braking resistor overload I

2

t

• Read the battery value in 10.39

• Increase the resistor ohmic value

• Check that 10.30 and 10.31 are set correctly

(braking cycle too long)

• Check the resistor wiring

• Check the integrated transistor

Oht1 IGBT temp. IGBT overheating (sensor)

• Reduce the motor load, the cycle, the

switching frequency, and the acceleration and

deceleration ramps

Oht2 RF int. temp. Internal resistor overheating (sensor)

• Reduce the switching frequency

• Reduce the cycle and the motor load

OI.AC

Drive output

curr.

Overcurrent at drive output

or instability and vibration

*

• Check the motor insulation and connection

• Increase the acceleration and deceleration

ramps

• Perform another calibration

• Check the wiring, coupling and the speed

feedback signals ( )

• Reduce the speed loop gains 29 and 30 ( )

• Reduce the current loop gains 31 and 32

OI.br

Brake IGBT

curr.

Braking IGBT overcurrent

• Check the resistor insulation

• Correct the short-circuit at the resistor output

• Set a higher resistor ohmic value

OLd1 +24 V Ovrld. Overload on + 24V source or digital output • Check the total current consumption

3 - SWITCHING TO PROTECTIVE MODE – DIAGNOSTICS

Loading...

Loading...