Page 6

NOZZLE MAINTENANCE

1. If nozzle clogs, remove and disassemble the nozzle assembly.

2. Clean the openings of any obstructions and reassemble.

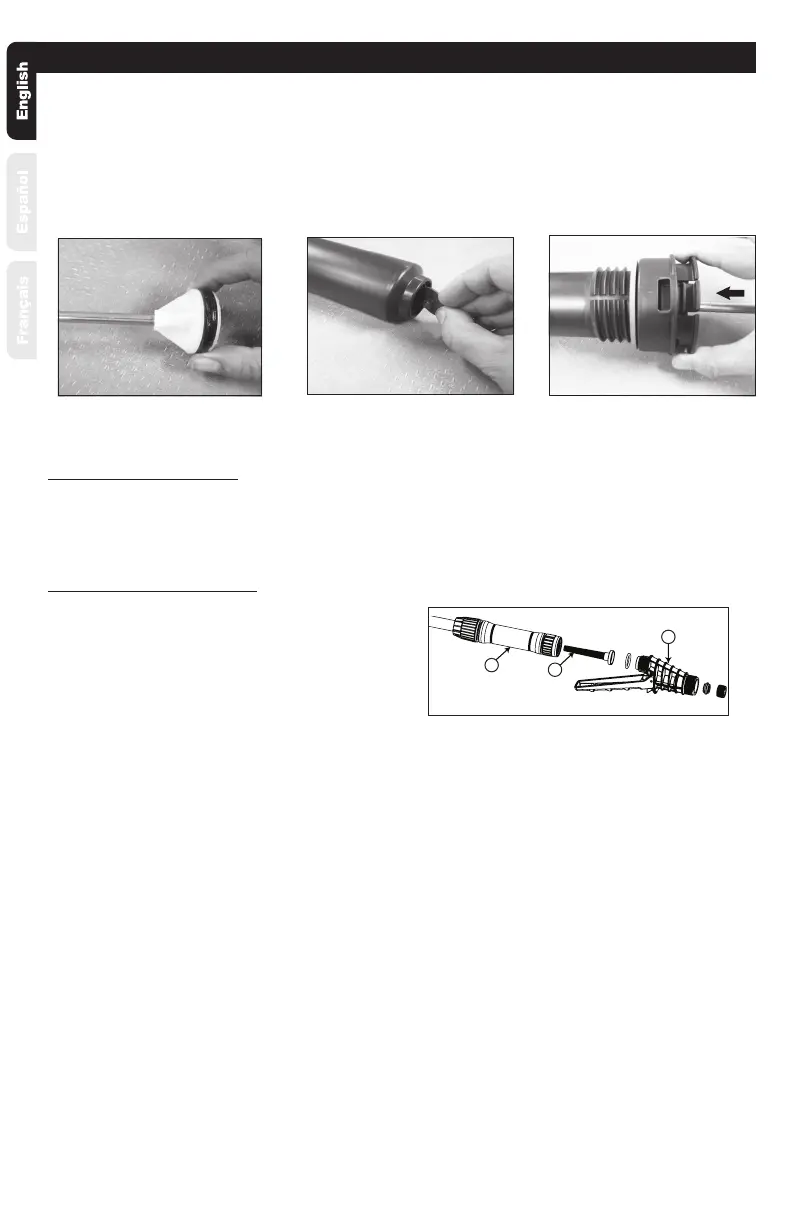

SHUT-OFF MAINTENANCE

Always depressurize sprayer before maintenance.

1. Unscrew the handle from the shut-o assembly.

2. Remove the lter from the shut-o assembly.

3. Clean any debris from inside the handle,

shut-o assembly, or the lter by rinsing with

cool, clean water.

4. Reassemble the components as shown and

tighten all connections securely.

A. Handle

B. Filter

C. Shut-o Assembly

MAINTENANCE CONTINUED

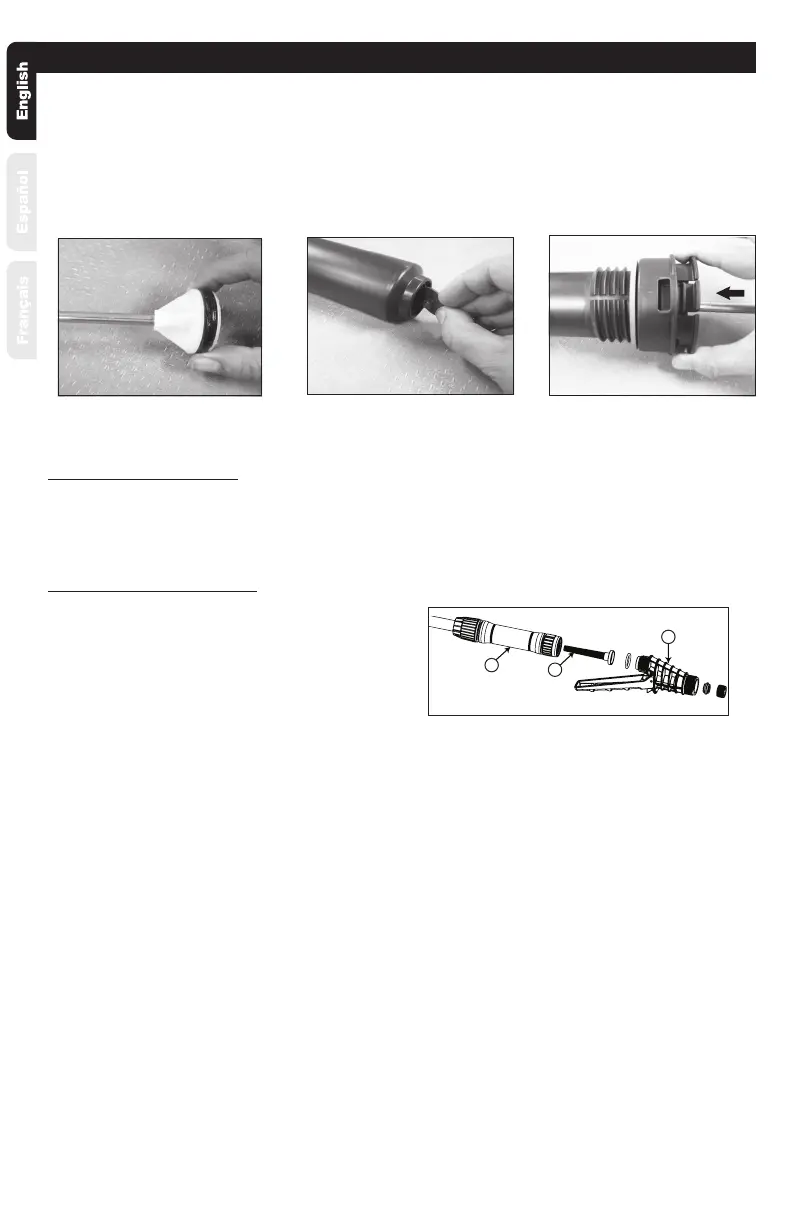

3. Inspect o-ring. If worn or damaged, remove and replace. Lubricate o-ring with petroleum jelly.

(See Figure 3)

4. Inspect check valve in bottom of barrel. If worn or damaged, remove and replace by pressing into

hole in bottom of barrel. (See Figure 4)

5. Insert the pump handle assembly into the barrel. Align the tabs of the pump cap with the rectangle

cutouts on the barrel. Push cap into place until the cap snaps securely into position. (See Figure 5)

Figure 3 Figure 4 Figure 5

A

B

C

Loading...

Loading...