What to do if safety configuration is not compatible (unknown resolution) on Leuze electronic Scanner?

- EEmily HernandezSep 16, 2025

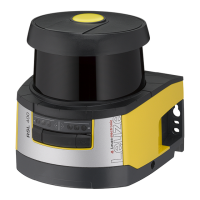

To resolve a safety configuration incompatibility (unknown resolution) on your Leuze electronic Scanner, swap out the safety sensor or change the configuration. The type of safety sensor must be the same as the type stored in the connection unit or in the Sensor Studio software.