8

Electric/Hydraulic Stern Thruster

Models 185TT, 250TT & 300TT

9

Electric/Hydraulic Stern Thruster

Models 185TT, 250TT & 300TT

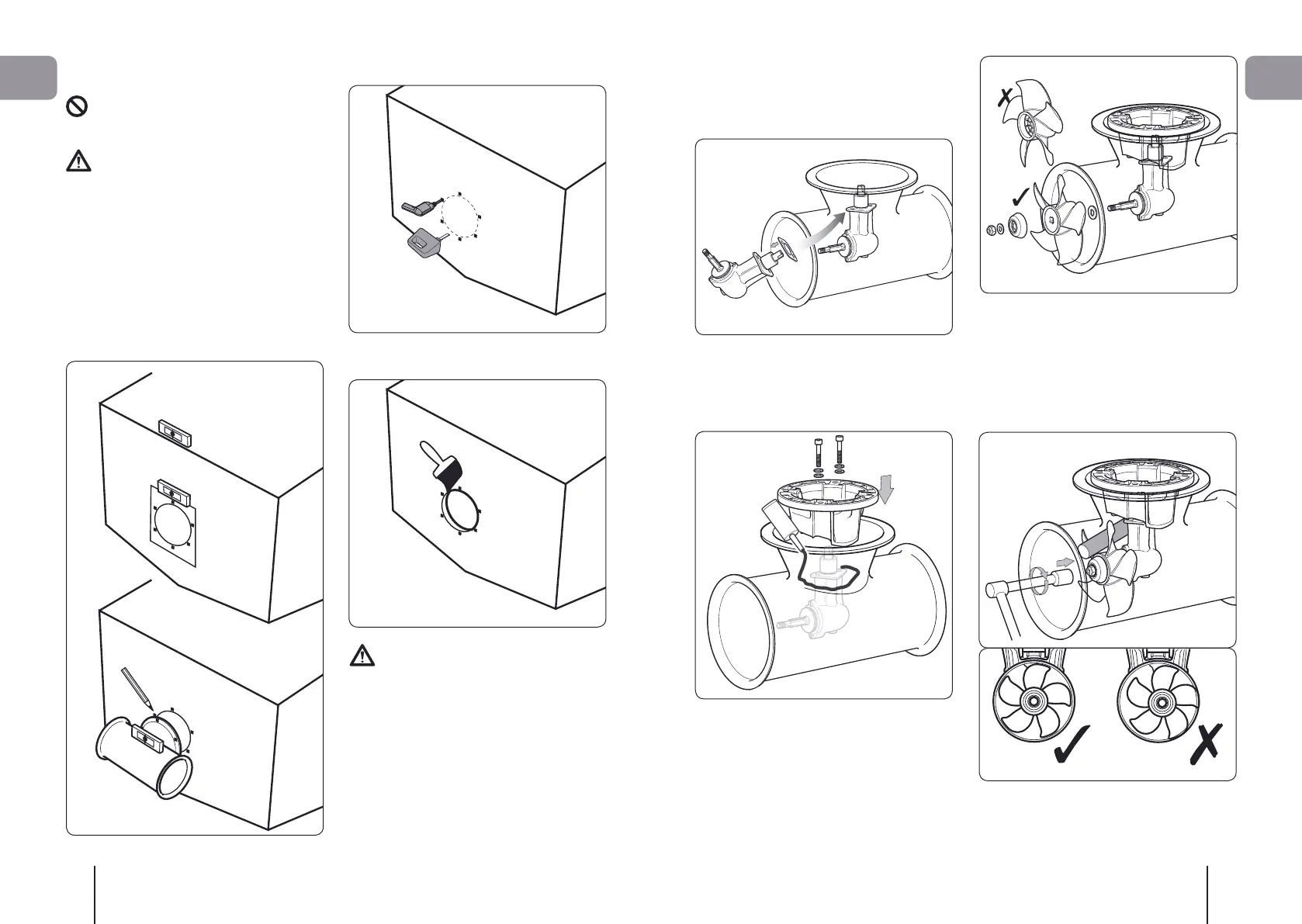

1.3 Preparing for fitting

The boat must be out of the water, levelled and

secure in its cradle.

A competent, marine engineer must carry out any

work on the hull of your boat.

Problems caused by faulty installation of the

tunnel are the installers full responsibility.

NOTE: Lewmar stern tubes are constructed

of polyester resin and glass fibre with a white

gell coat. Mounting template is provided with

the kit.

• Align template horizontally on transom.

OR

Offer up stern tube and level, mark holes for

drilling.

• Drill and cut all holes.

Fig. 1.31

• Seal all cut surfaces. (GRP Only).

Fig. 1.32

Stern tubes may be bonded in place. We

recommend that a qualified person carry out any

work to the hull. Faulty installation will place the

boat and crew in danger and make the warranty

invalid.

Fig. 1.33

1. Installation

Fig. 1.31

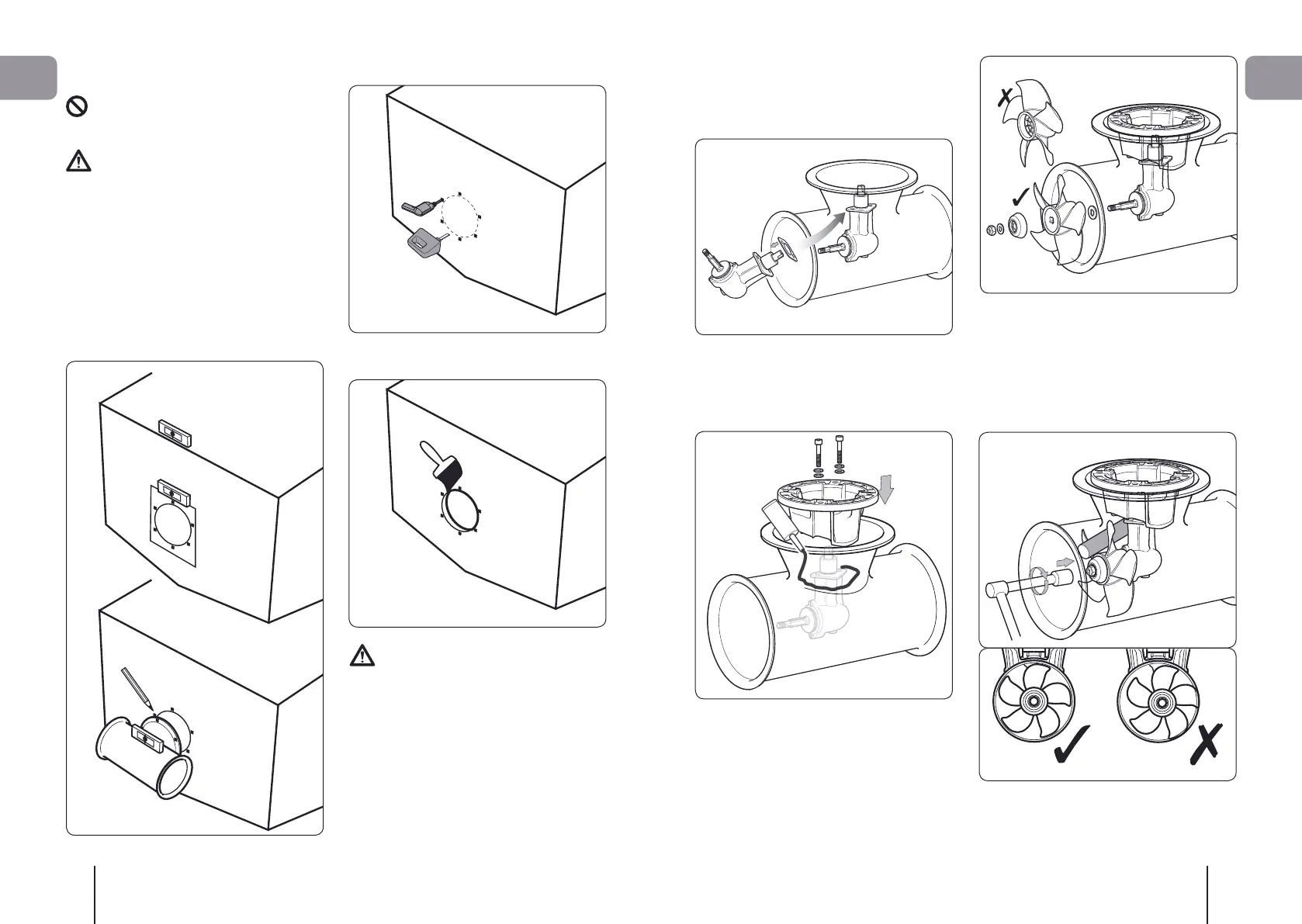

1.4 140TT & 185T T

Installing hub unit

• Place gasket on hub and locate through centre

hole.

• Apply zinc chromate paste or marine grease

to location bore and assemble saddle onto hub

(sicoflex or similar maybe used to seal saddle

in place). Apply blue loctite to bolts and hand

tighten along with supplied washers.

Fig. 1.32

• Assemble anode kit and propeller in this order:-

large washer, propeller, anode, small washer and

nyloc nut onto propeller shaft.

Tighten hub/saddle bolts to 7Nm (x.xlbs.ft)

140TT - 21Nm (15.5lbs.ft) 185TT. Check that

propeller is centred and free turning (within 10

minutes of applying Blue Loctite).

Fig. 1.33

• Tighten prop nut to 10Nm (7.4lbs.ft) 140TT

- 15Nm (11lbs.ft) 185TT , a length of wood

placed between prop blade and tunnel will stop

movement.

NOTE: Poor internal tunnel surface could cause

leakage. Apply sealant to this area and gasket

if in doubt.

Fig. 1.33

• Antifoul bronze hub.

Loading...

Loading...