1. Application Range

This spec sheet is applied all of the LW81B Chassis

(Hurricane-5).

2. Specification.

2.1 Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

2.2 Adjustment must be done in the correct order.

2.3 The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

2.4 The input voltage of the receiver must keep 100~220V,

50/60Hz.

2.5 The receiver must be operated for about 15 minutes prior

to the adjustment.

• After Full White in HEAT-RUN Mode, the receiver must be

operated prior to the adjustment.

• Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display 100% full WHITE

PATTERN.

- Set is activated HEAT run without signal generator in this

mode.

- Single color pattern ( RED / BLUE / GREEN ) of HEAT RUN

MODE uses to check panel.

- Caution : If you turn on a still screen more than 20 minutes

(Especially digital pattern, cross hatch pattern), an after

image may be occur in the black level part of the screen.

3. Adjustment items

3.1 PCB assembly adjustment items

Download the MSTAR main software (IC1215, Mstar ISP Utility)

3.2 SET assembly adjustment items

DDC Data input.

Adjustment of White Balance.

Factoring Option Data input

4.

PCB assembly adjustment method

(Using MSTAR Download program)

4.1 S/W program download

4.1.1 Preliminary steps

(1) Download method 1 (PCB Assy)

(2) Connect the download jig to D-sub jack

4.1.2 Download Steps

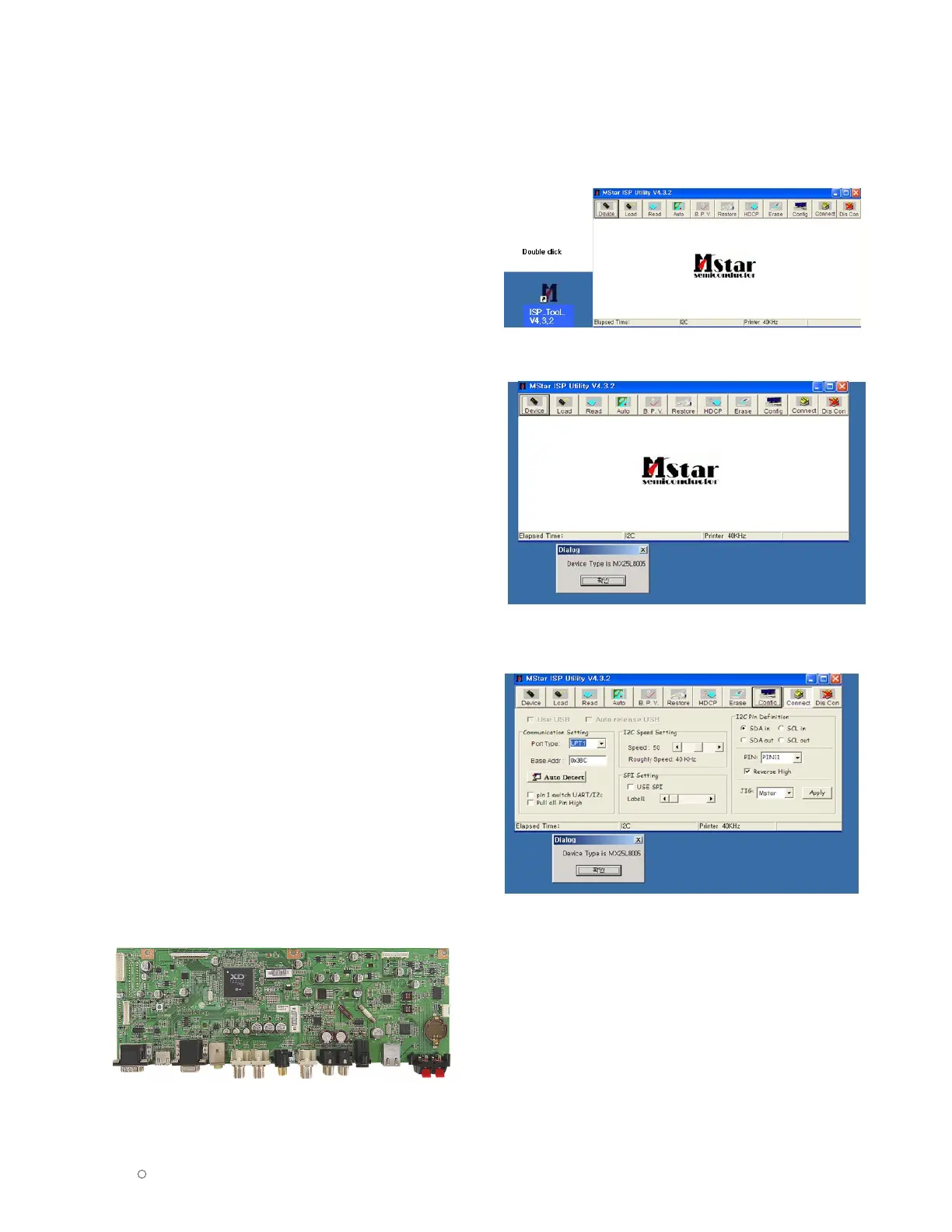

(1) Execute ‘ISP Tool’ program in PC, then a main window will

be opened

(2) Click the connect button and confirm “Dialog Box”.

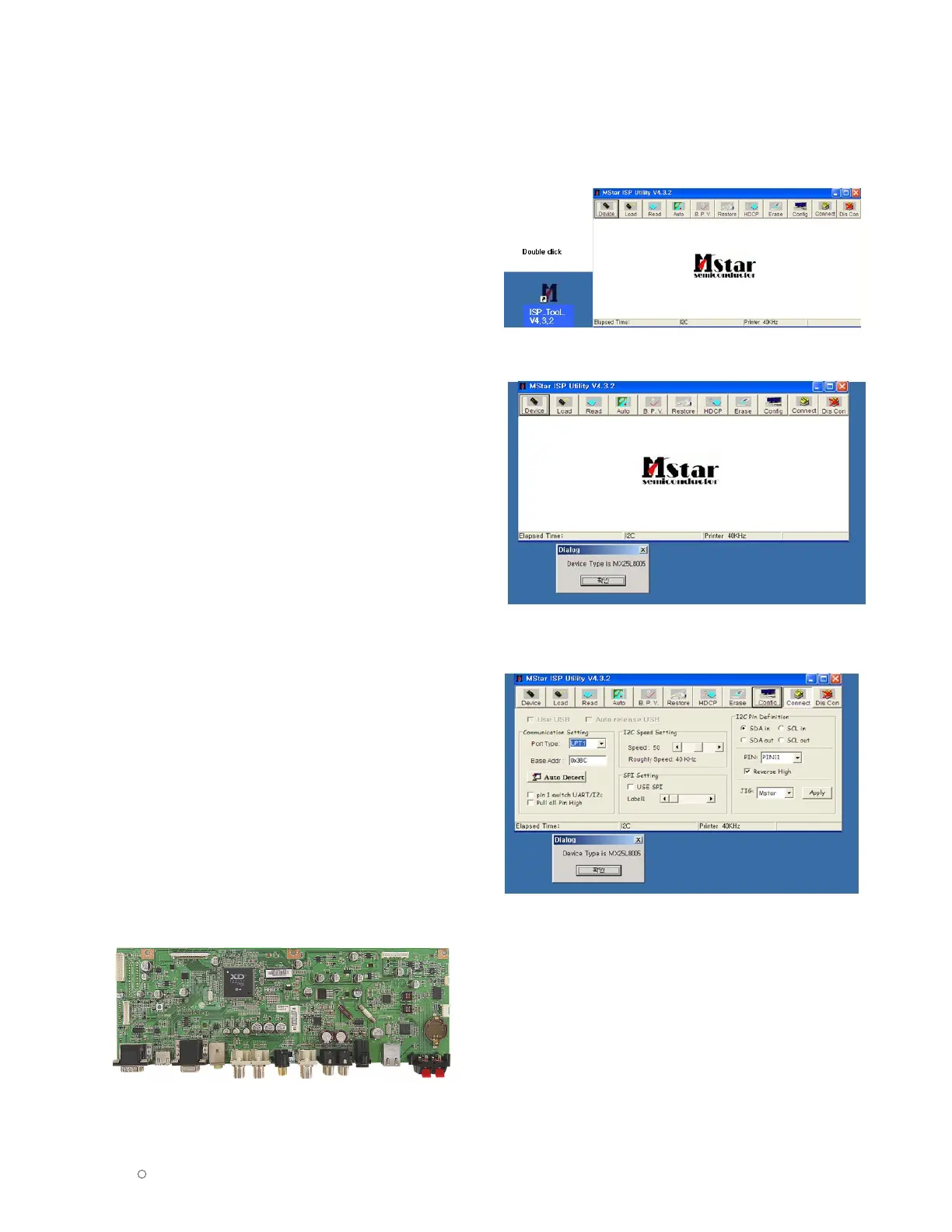

(3) Click the Config button and Change speed

E2PROM Device setting : over the 350Khz

Loading...

Loading...