3. Installation of outdoor unit

63 _ Heat pump 50Hz/R410A

Part 3 Design and installation

⑤

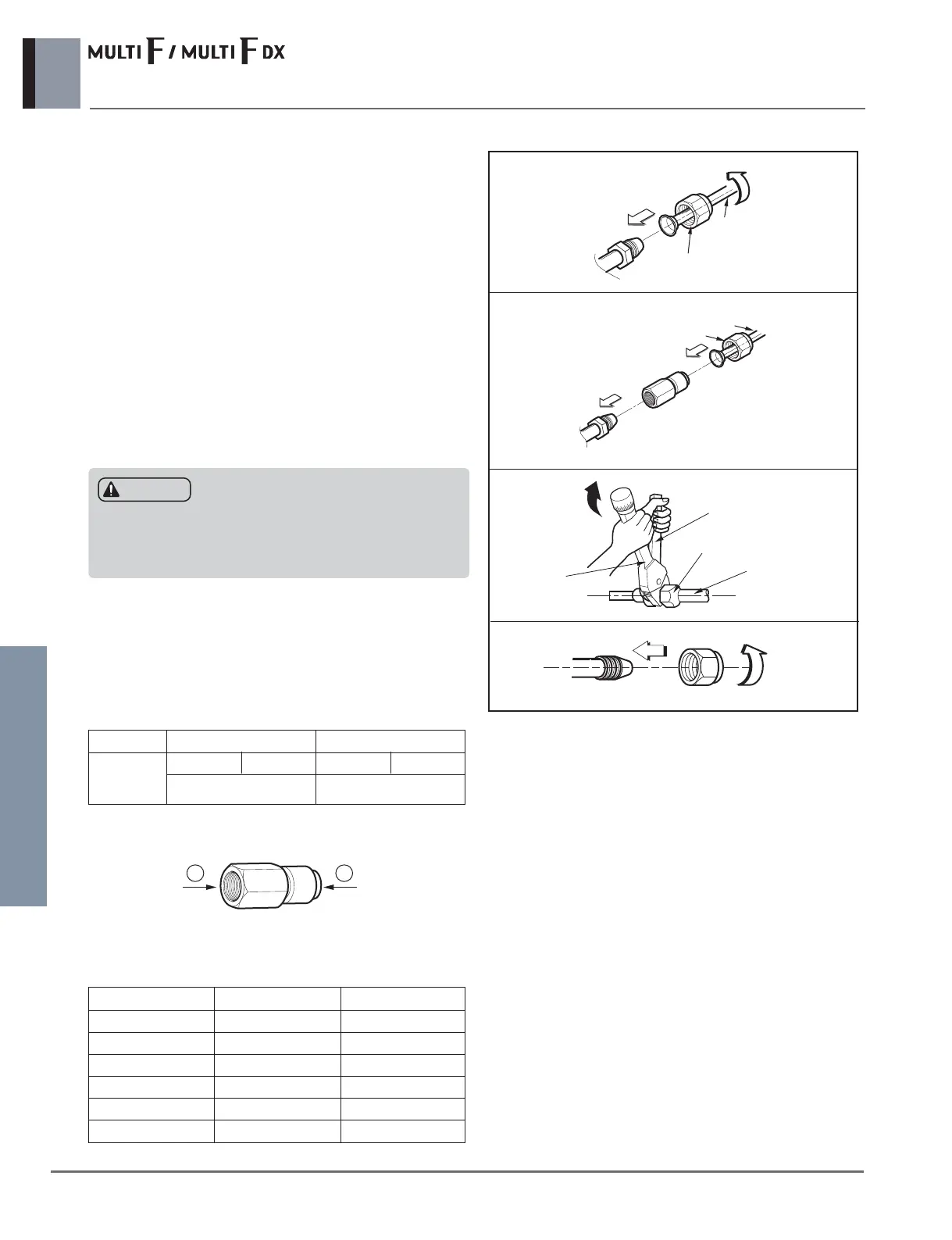

Branch pipe connection (BD unit ÷ indoor unit)

a) While piping installation you must use the connector.

• PMBD36** BD Unit

b) Align the center of the pipings and sufficiently tighten the

flare nut by hand

*Connecting pipe size

Indoor Units Gas Liquid

18k, 24k

ⓐⓑⓐⓑ

Ø9.52(3/8)’Ø12.7(1/2) Not necessary

Indoor Units Gas side Liquid side

5k Ø9.52(3/8) Ø6.35(1/4)

7k Ø9.52(3/8) Ø6.35(1/4)

9k Ø9.52(3/8) Ø6.35(1/4)

12k Ø9.52(3/8) Ø6.35(1/4)

18k Ø12.7(1/2) Ø6.35(1/4)

24k Ø12.7(1/2) Ø6.35(1/4)

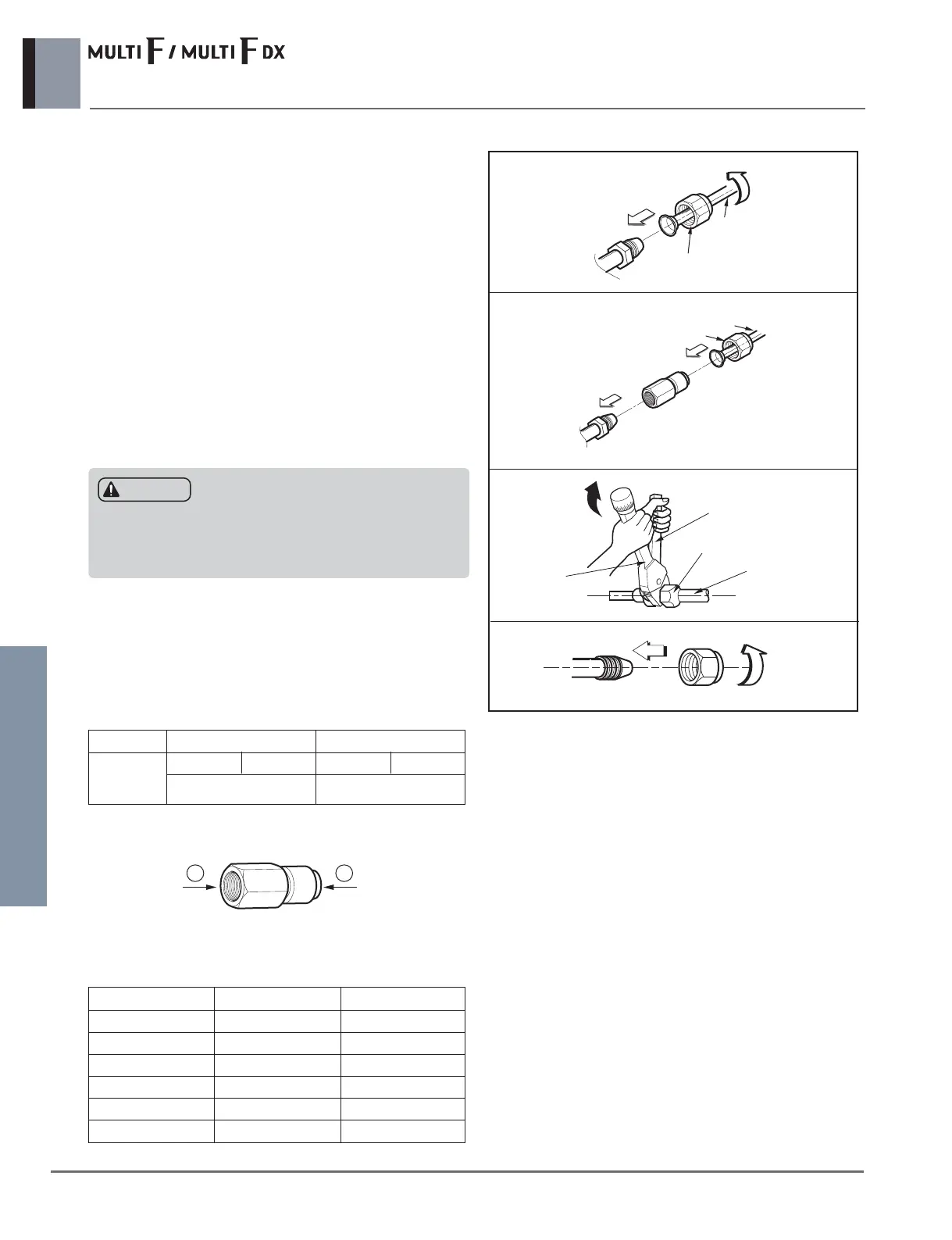

[Connector]

a

b

[Unit : mm(inch)]

[Unit : mm(inch)]

a) Align the center of the pipings and sufficiently tight-

en the flare nut by hand.

b) Tighten the flare nut with a wrench.

c) Wrap the insulation material around the connect-

ing portion.

① Overlap the Refrigarant cable insulation material and the

indoor unit pipe insulation material. Bind them together

with vinyl tape so that there is no gap.

② Wrap the area which accommodates the rear piping

housing section with vinyl tape.

③ Align the center of the piping and sufficiently tighten the

brass cap by hand.

④ Tighten the brass cap with a wrench.

⑤ Wrap the joint part with insulation.

Flare nut

Pipes

CASE. 1

BD Unit side flare

BD Unit side flare

Indoor unit side flare

Indoor unit side flare

Ø 9.52(7k/9k/12k Btu/h)

Connecting socket

Flare nut

Pipes

CASE. 2

Ø 9.52

Ø12.7(18k/24k Btu/h)

Ø 9.52

Spanner (fixed)

Connection pipe

Flare nut

Torque

wrench

• Never use the plastic cap for sealing.

• Make sure to use brass cap with the end of pipe sealed or

welded tightly.

CAUTION

Loading...

Loading...