SYSTEM ENGINEERING

| 73

HEAT PUMP CONDENSING UNIT ENGINEERING MANUAL

Due to our policy of continuous product innovation, some specifications may change without notification.

© LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Refrigerant Pipe Connections

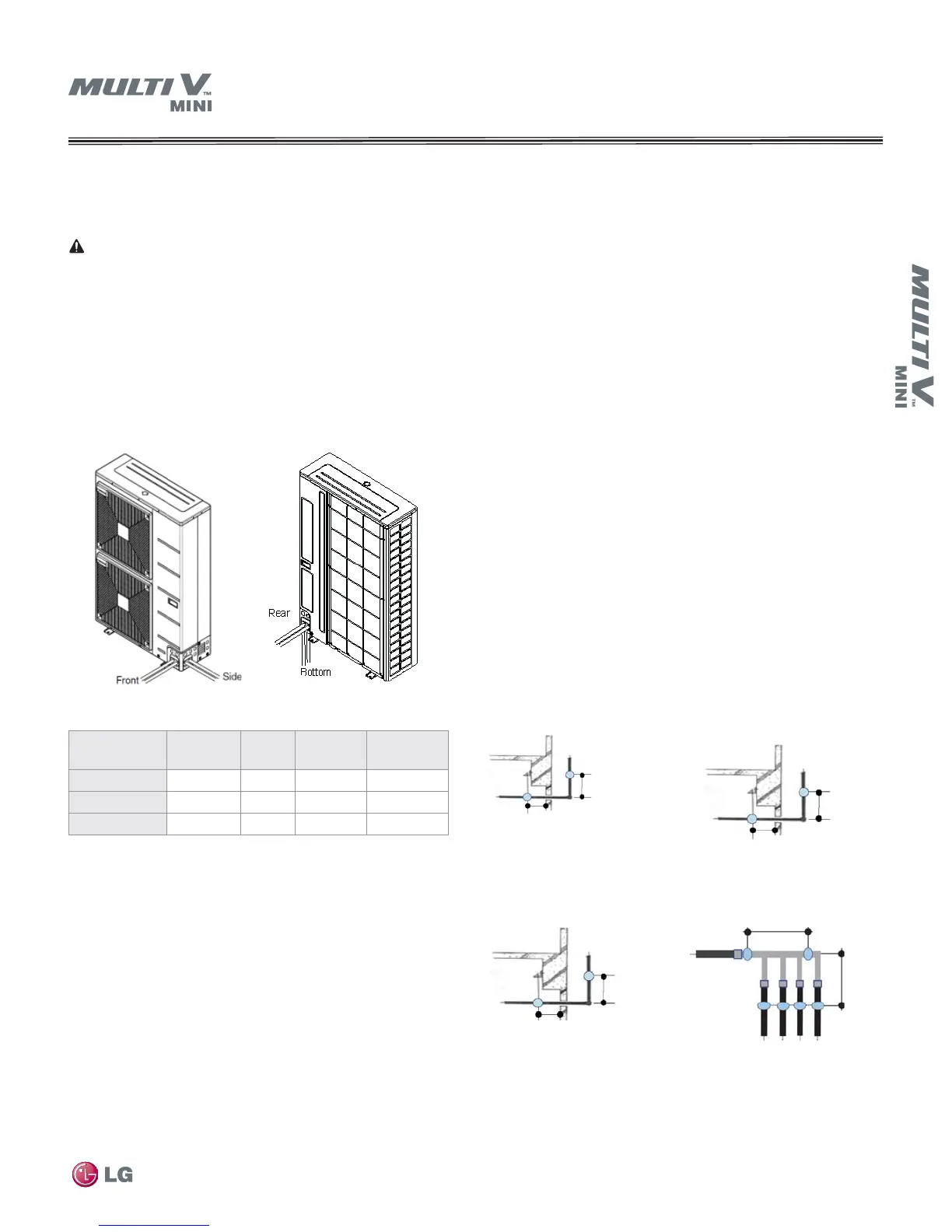

Note: When routing field-provided tubing inside the out-

door unit case, take care to avoid vibration damage to the

tubing. Mount the tubing so it does not make contact with

the compressor, unit casing, terminal cover, or mounting

bolts. Allow room for field installation.

Properly insulate fi eld-provided tubing inside the confi nes

of the unit casing.

Refer to Figure 44 for unit pipe connection options and

Table 27 for outdoor unit connection types.

Pipe Supports

A properly installed pipe system should be adequately supported to

avoid pipe sagging. Sagging pipes become oil traps that could lead

to equipment malfunction. Field-provided pipe supports should be

designed to meet local codes. If allowed by code, use fiber straps

or split-ring hangers suspended from the ceiling on all-thread rods.

Supports should never touch the pipe wall. Insulate the pipe first.

Place a second layer of insulation over the pipe insulation jacket to

prevent chafing and compression of the primary insulation within

the confines of the support pipe clamp. Pipe and insulation should

be allowed to move linearly as pipe temperature changes.

• Straight segments up to 3/4 inch OD should be supported at

least every 5 feet or per local codes if more stringent.

• Straight segments of 1 inch OD and larger copper pipe should

be supported every 6 feet or per local codes if more stringent.

• A properly installed pipe system will have sufficient supports

to keep pipes from sagging during the life of the system. As

necessary, place supports closer for segments where potential

sagging could occur.

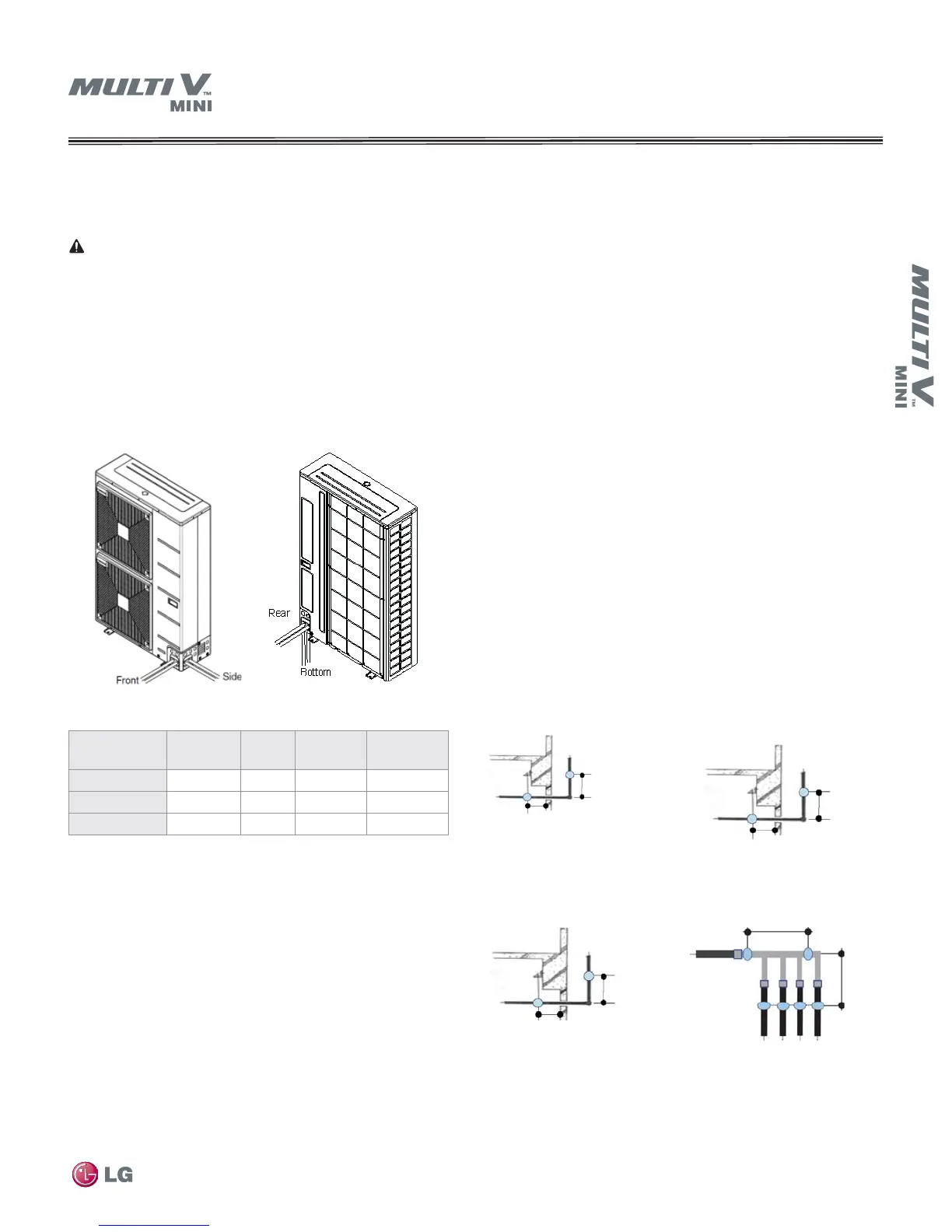

Wherever the pipe changes direction, place a hanger within 12

inches on one side and within 12 to 19 inches of the bend on the

other side as shown in Figure 45. Support piping at indoor units

as shown in Figure 46. Support Y-Branch and Header fittings as

shown in Figure 47 and Figure 48.

Figure 44: Outdoor Unit—Refrigerant Pipe Connections Options

Table 30: Outdoor Unit Refrigerant Pipe Connections

Model

Liquid Conn

(inches)

Type

Vapor Conn

(inches)

Type

ARUN036GS2

3/8 Braze 5/8 Braze

ARUN047GS2

3/8 Braze 5/8 Braze

ARUN053GS2

3/8 Braze 3/4 Braze

Figure 47: Pipe Support at

Y-Branch Fitting

PIPING DESIGN GUIDE

Figure 46: Pipe Sup-

port at Indoor Unit

Figure 45: Typical Pipe Sup-

port—Change in Pipe Direction

Figure 48: Pipe Support at

Header

~12"–19"

Max. 12"

Max. 12”

~ 12” – 19”

A

A+B ~ 12"–19"

B

Max. 12"

Max. 12"

Max. 12"

Max. 12"

Max.

Max. 12”

~ 12” – 19”

Max. 12”

Loading...

Loading...