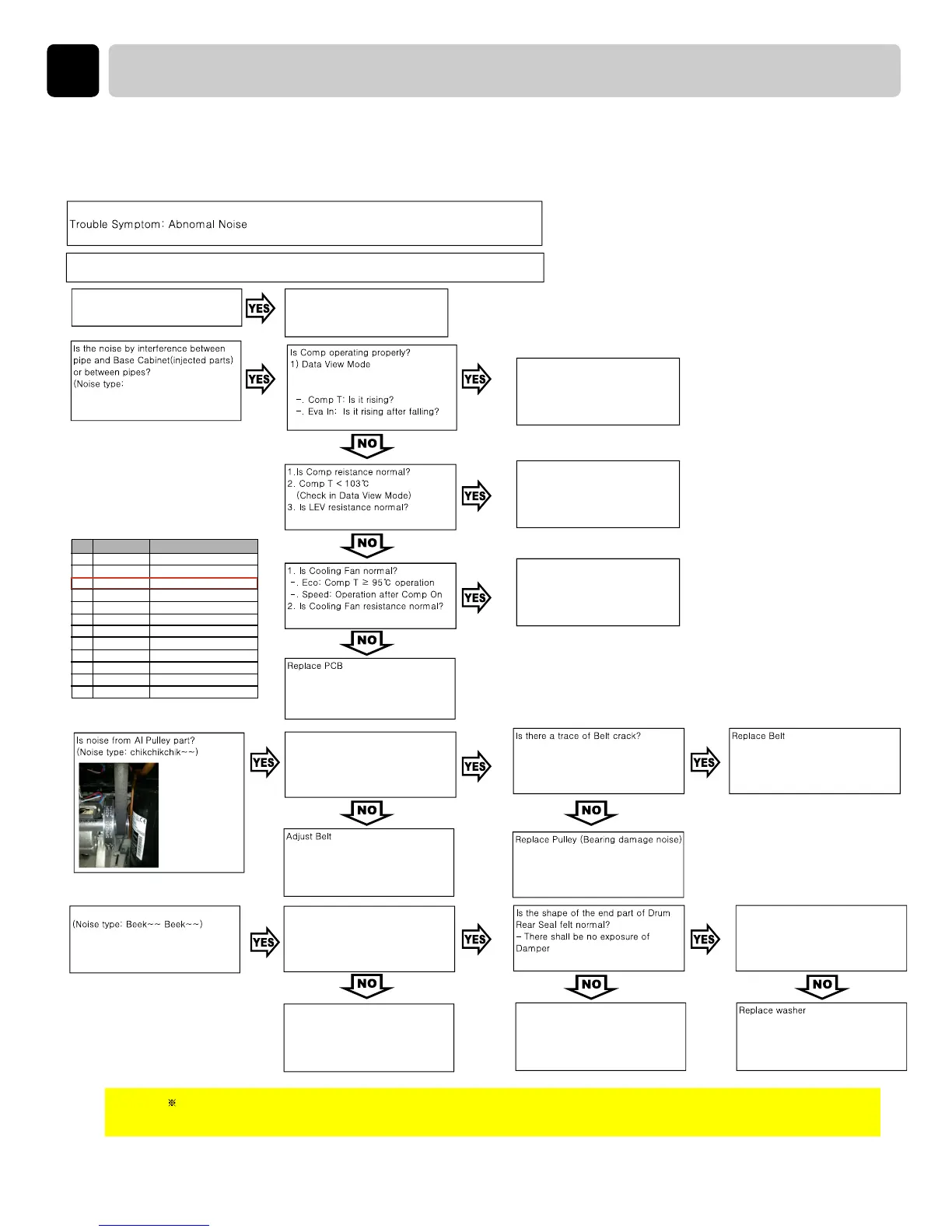

Measurement condition : Check if they are working when connected to power supply.

Is the product leveled?

(Check shaking / tilt )

Adjust product leveling

(Refer to how to leveling, Page 10)

Adjust pipe position to insure minimum

5mm gap with pipe or mold

Adjust pipe position to insure minimum

5mm gap with pipe or mold

Is Belt properly assembled to Pulley?

Is Journal Bearing grease properly

Sprayed?

( Refer to exploded view ,

Refer to picture C page35 )

Replace Journal bearing (D122)

Refer to picture A , page35

Replace real seal (D152)

Note: The roler noise (dung dung dung) at the initial operation, and pump and water flowing noise during auto cleaning

TM

are normal noises of the

product. If noise of metal materials bumping each other occurs, check if screw is properly locked or if it is properly assembled.

Is the washer between Drum and

Rear cover flat?

( Refer to picture D , page35 )

2) After Comp on, check corresponding

thermistor temp.

ta ~ ta~ ta~ sound)

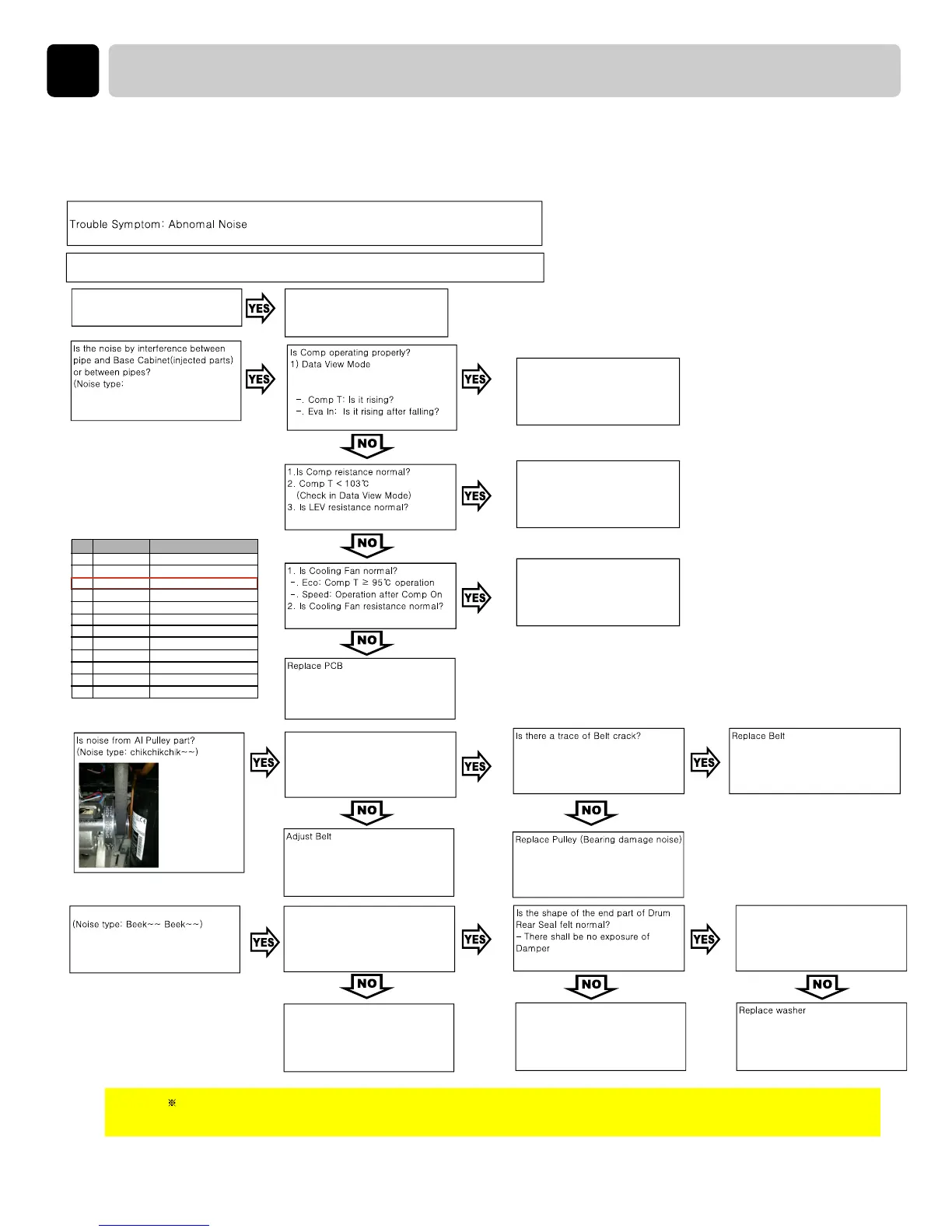

NO The course Show details

1

2

3

4

5

6

7

8

9

10

11

12

Refresh

Skin Care

Jeans

Bulky Item

Easy Care

Mixed Fabric

Cotten

Sports Wear

Quick Dry

Delicate

Wool

Rack Dry

Humidity values

Low Temp

Comp Temp

T_heater (High Thermistor)

Eva in Temp

Sump Water Level

Drain Pump RPM

LEV Pulse

Main PGM Tool

Main Version

※Check the status of the actions Sensor

- Drum Light + Buzzer 3 when entering

Pressing enter, Once again press the same key

fot three seconds to escape.

- Turn the Jog Dial in data view state data can be

checked as shown below.

- Not to enter the Child lock status.

- Apply the model : Only Touch LED model.

Loading...

Loading...