Site Preparation and Installation

31

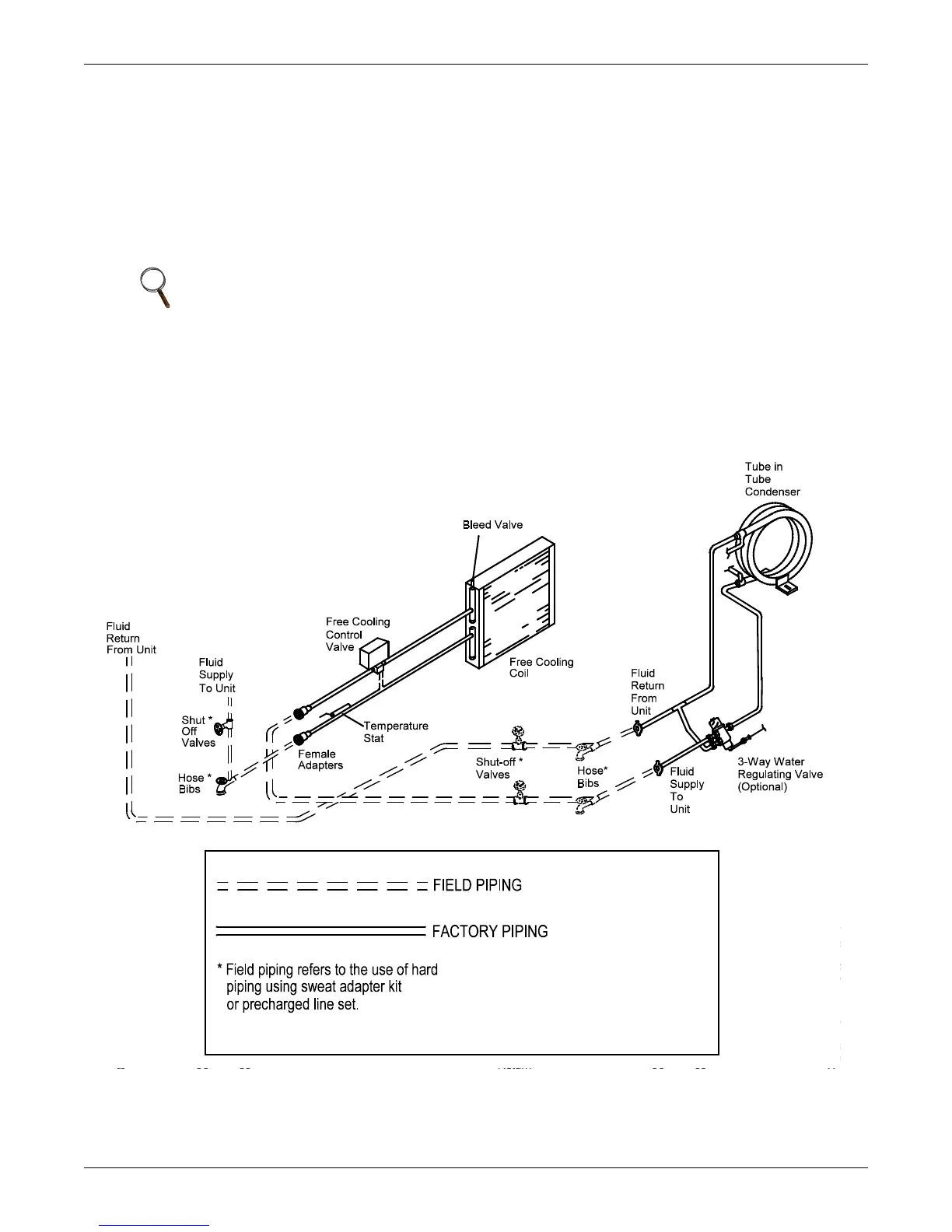

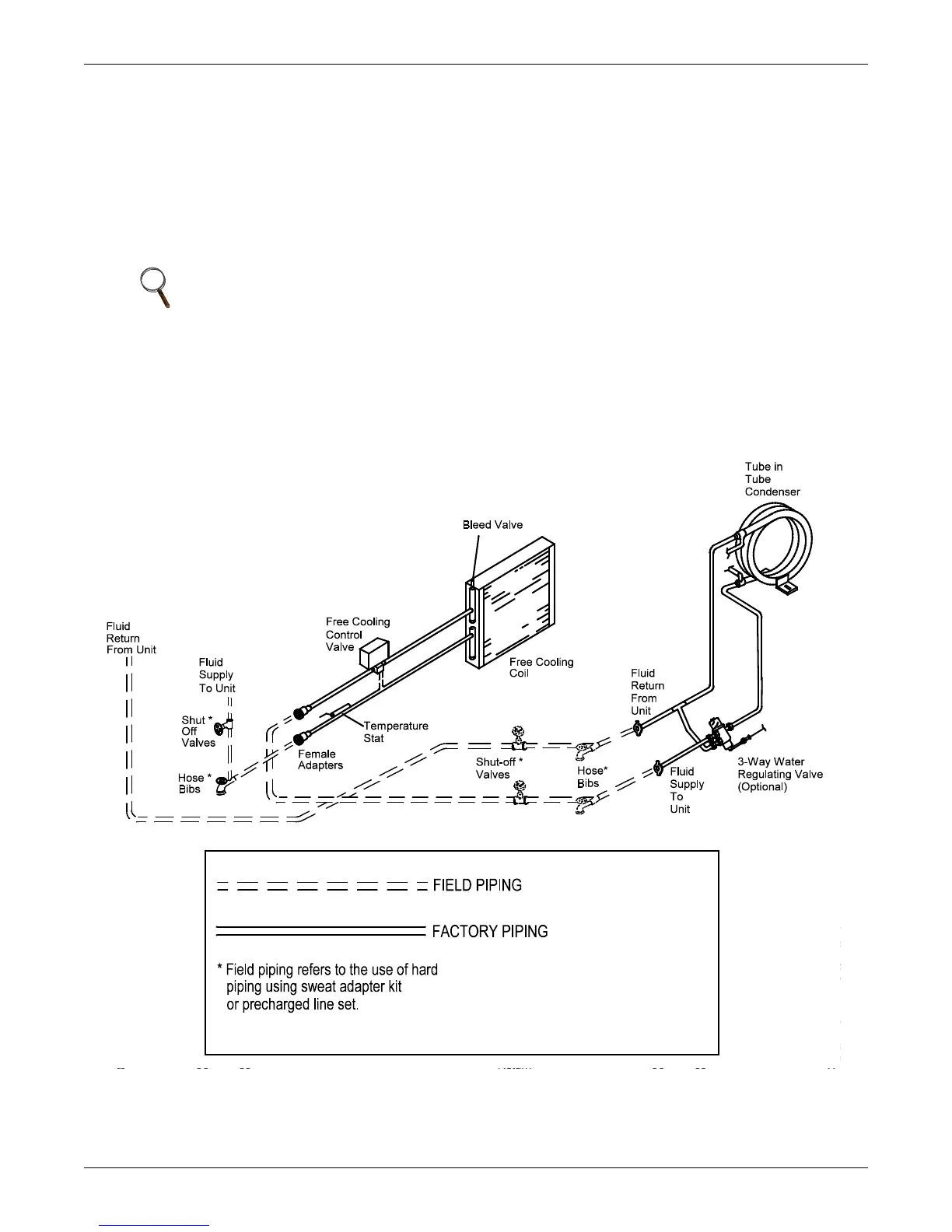

2.8 Optional Equipment Piping

2.8.1 Free-Cooling Coil (GLYCOOL)

The free-cooling coil is a secondary coil located upstream of the DX coil. To take maximum advantage

of available free-cooling, the secondary coil may operate at the same time as the DX coil. A tempera-

ture sensor is factory-mounted to the free-cooling piping. When fluid temperature is sufficiently below

the room temperature, cooling is provided by circulating the fluid through the secondary cooling coil

(flow is controlled by a motorized valve). Compressors are staged on if needed to supplement the free-

cooling. To keep deposits from building up in the free-cooling coil, the coil is flushed periodically.

On water-cooled systems, the free-cooling coil outlet can be field piped to the condensing unit inlet,

provided a 3-way regulating valve has been installed within the water/glycol condensing unit (see

Figure 21).

Figure 21 Optional free cooling coil (3-way valve) on water/glycol units

NOTE

If the free-cooling coil is piped to an open water tower, a CU/NI (cupro-nickel) type coil must

be ordered to prevent corrosion of the copper tubes; or a heat exchanger must separate the

tower water from the free-cooling loop.

SL-11088Pg12

Loading...

Loading...