HSILGNE

1 WIRING AND CONNECTIONS

• Before commencing wiring and connection work, read the SAFETY INSTRUCTIONS AND WARNINGS and INSTALLATION INSTRUCTIONS

AND WARNINGS Chaps carefully.

• All wiring and connection operations must be carried out with the control unit disconnected from the electricity supply. If the disconnection

device is not in view, display a sign reading: “ATTENTION: MAINTENANCE WORK IN PROGRESS”.

1.1 List of electric cables

The cables needed may vary depending on the installation and type and quantity of devices installed.

The cables used in the installation must be IEC 60335 compliant.

ATTENTION: the cables used must be suited to the type of installation. It is the Fitter’s

responsibility to choose appropriate material.

•

The power cable may be no lighter than 60245 IEC 57 ( HO5RN-F).

• Inside the power cable, one wire must be yellow and green.

• The power cable coating must be composed of a polychloroprene sheath.

• All wires must be unsheathed as little as possible (6mm at the most) and as close as possible

to the connection terminals, in order to prevent accidental contact with live parts in the event

that cables disconnect from the terminals.

• Do not pre-seal cables to be fastened to the terminals using screws.

• If it is possible that wires subject to voltage higher than 50 Volt RMS and very low voltage

safety wires may come into contact with one another, wires with voltage higher than 50 volt

RMS must be insulated with a sheath; or the very low voltage safety wire must have an

insulating sheath at least 1mm thick

• All external connection cables must not be of the flat twin tinsel cord type.

• A power cable fastening device must be provided. Assemble the power cable so that if it comes out of its fastening device, the neutral and live wires

are taut before the earth wire.

1.2 Setting up the electric system and connection to the mains supply

This manual does not describe how the electrics system should be prepared for connection to the mains. It does, however, give the following warnings:

• The electricity supply line must be installed and connected by an authorised electrician or professional fitter.

• The electricity supply must be adequately protected against short circuits and static discharge.

• The power supply network must contain an omnipolar disconnection device with an opening distance of the contacts equal or greater than 3.5 mm

that assures the complete disconnection of the power supply.

1.3 Control unit connections

Fitters must make the connections of the 230 Vac 50 Hz electricity supply, and the various automation devices.

Connections between the control unit, motor, encoder and transformer have already been performed by the Manufacturer.

• Once the connections to the control unit have been made, the Fitter must use bands to join adjacent wires into groups of 2, 3 or 4 in order to prevent

them coming away from the terminal board: bands must be attached as close as possible to the terminals, no more than 10mm away, taking care

not to damage wire insulation. No cable may remain unpaired.

• The bands are only for unsheathed cables (sheathed cables are held in place by the sheath).

• Pay careful attention not to pair wires with voltages higher than 50 Volt RMD with lower voltage wires.

• The wiring performed internally by the manufacturer is already equipped with clamping bands.

ATTENTION: for safety reasons, it is essential to earth the motor.

5

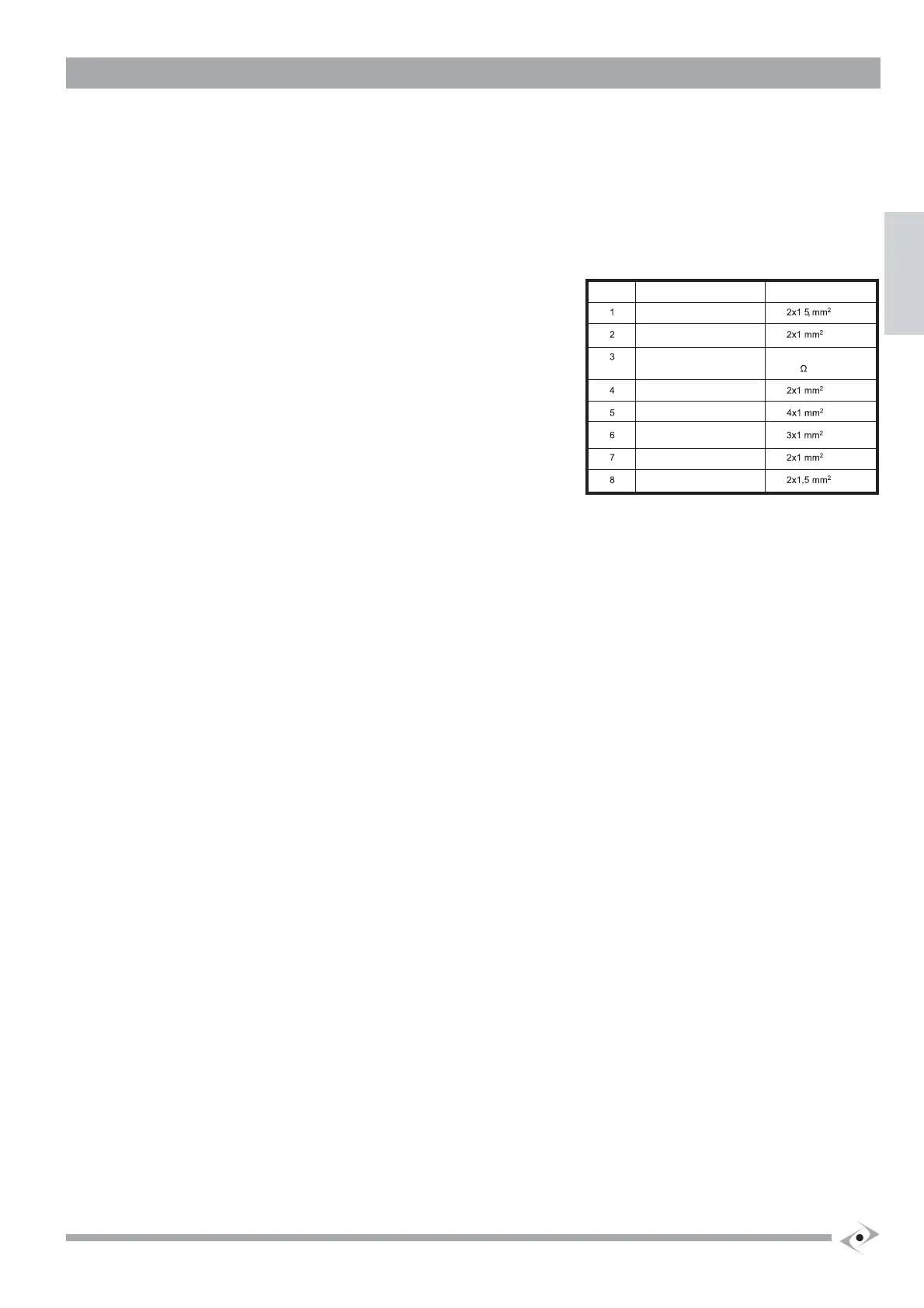

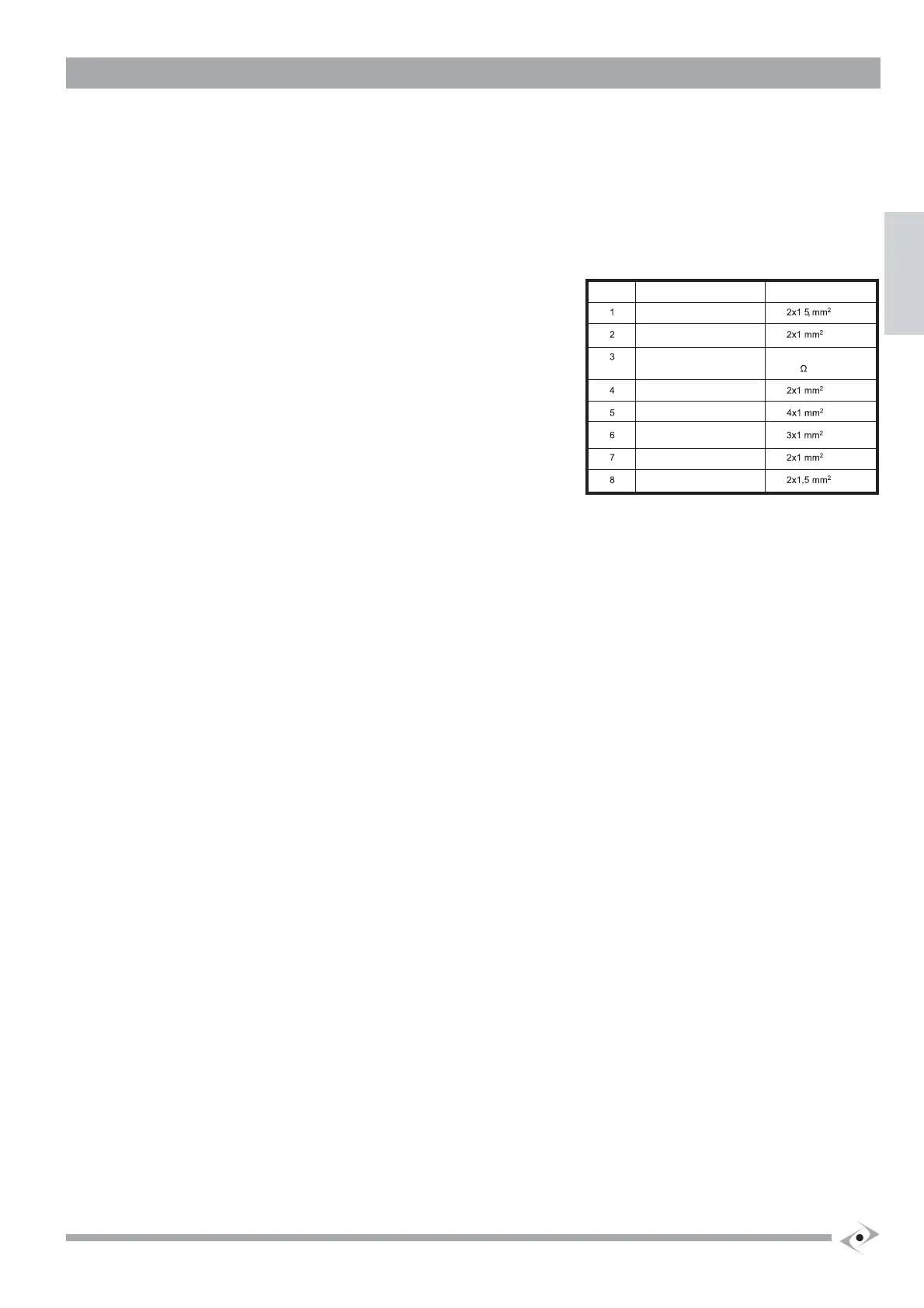

Pos. Type of cable

%LECTRICITYSUPPLYLINE

%LECTRICITYSUPPLYLINE

&LASHINGLIGHT

2ADIOAERIAL

4X0HOTO

2X0HOTO

3ELECTOR

%NCODER

3CREENED2'

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

CABLE

Connection

Loading...

Loading...