Do you have a question about the Lincoln Electric 11827 and is the answer not in the manual?

Essential safety advice including fume avoidance, PPE, and situational precautions.

Warnings regarding diesel exhaust and welding fumes as per California law.

Dangers of arc welding, protecting self and others, pacemaker users.

Potential risks from EMF fields and precautions for welders.

Critical warnings about electric shock, insulation, and safe practices.

Protection against hazardous arc rays, eye and skin protection.

Risks associated with welding fumes and gases, ventilation requirements.

Precautions against sparks, spatter, and flammable materials causing fire.

Dangers associated with compressed gas cylinders and explosion risks.

Safety guidelines for electrically powered welding equipment.

Details on input voltage/frequency, rated output amps/volts.

Recommended input wire gauge and fuse/breaker sizes for single phase.

Machine physical size, weight, and wire feed speed range.

Critical safety precautions before installing the equipment.

Procedures for uncrating the welder and selecting a suitable location.

Guidelines for connecting input power, grounding, and voltage selection.

Steps for connecting the welding gun and cable assembly to the machine.

Instructions for connecting the shielding gas supply to the welder.

Procedure for installing an air-cooled TIG torch for DC TIG welding.

Explains welding modes and common welding abbreviations used.

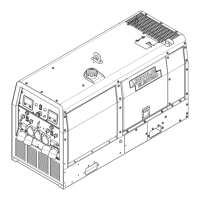

Details the machine's capabilities and identifies key control panel components.

Guide to selecting weld modes and adjusting parameters for optimal welding.

Explains various functions like Weld Mode, Preflow, Run-In, and Start.

How to adjust arc control, crater, burnback, and spot settings.

Covers drive roll installation, wire loading, and troubleshooting feed issues.

Details Pulse, Pulse-on-Pulse, Power Mode, and TIG welding processes.

Available drive roll kits and the Readi-Reel adapter for wire spools.

Kit for mounting two full-size gas cylinders side-by-side.

Information on available Magnum GMAW gun and cable assemblies.

Optional kit for using standard Magnum gun assemblies.

Routine cleaning procedures for the welder and its components.

Inspection and maintenance of drive rolls and guide plates for wire feeding.

Procedures for installing and maintaining contact tips and gas nozzles.

How to clean the gun cable liner to prevent feeding problems.

Steps for removing, installing, and trimming the gun liner.

Introduction to the troubleshooting process and safety warnings.

Diagnosing and resolving issues like physical damage, power, output, and thermal faults.

Troubleshooting low output, poor arc, and wetting problems.

Identifying and fixing issues with wire feeding, including jams and stops.

Troubleshooting issues related to gas not flowing during welding.

Understanding error codes and display messages for diagnostics.

Resolving problems specific to push-pull wire feeding operations.

Adjusting stall factor and performing a machine reset procedure.

Schematic showing electrical connections for code 11827.

Detail of connections on various printed circuit boards.

Schematic showing electrical connections for code 12875.

Visual representations of the machine's physical dimensions.

Policy regarding advice and information provided by Lincoln Electric.

| Brand | Lincoln Electric |

|---|---|

| Model | 11827 |

| Category | Welding System |

| Language | English |

Loading...

Loading...