B-2

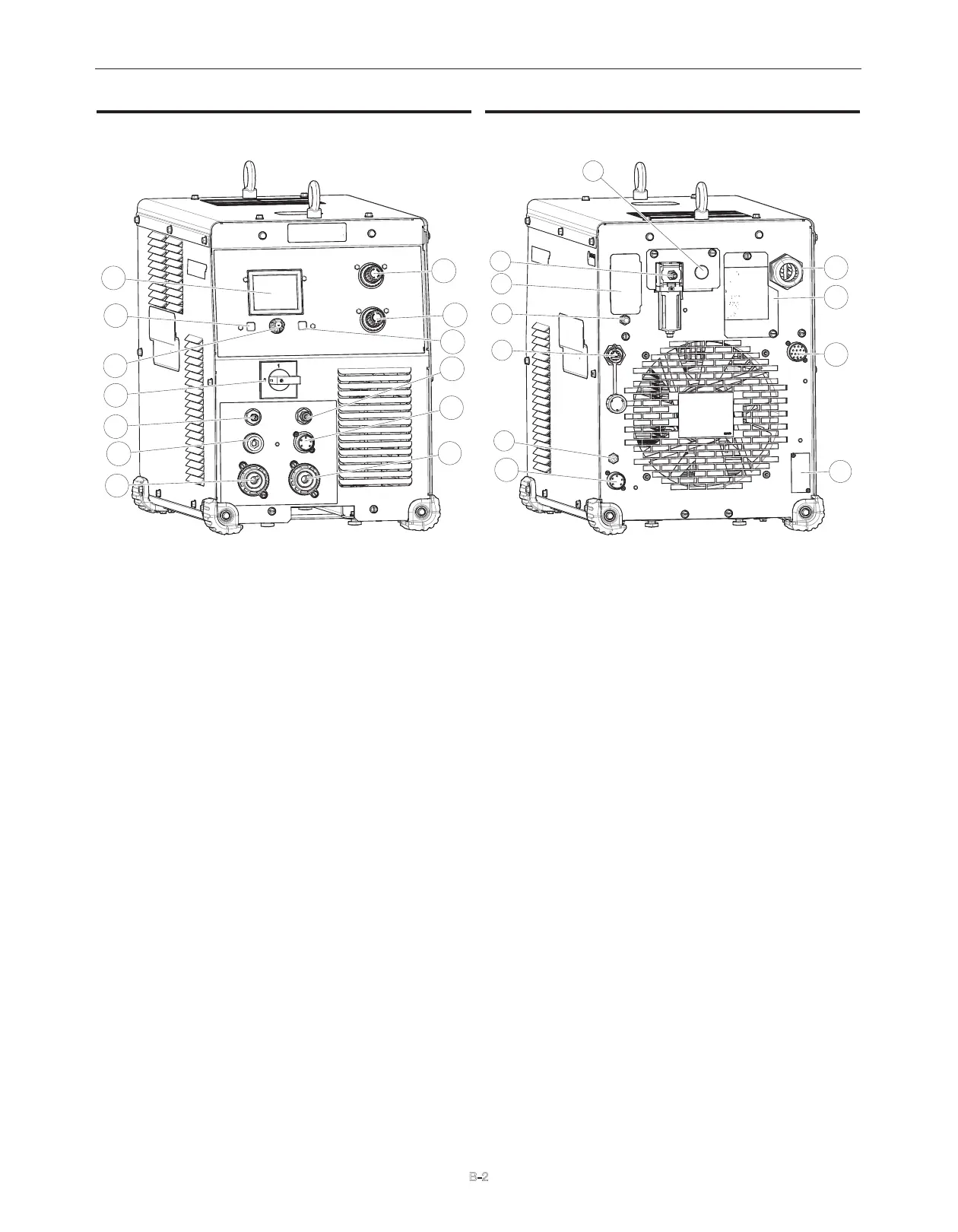

FIGURE B.1

1. LCD Display: Shows available modes and real time

parameters and system errors.

2. Home Button: Allows the user to return to the Home Screen

3. Menu Control Knob/Button: Used to navigate and select items

on the display.

4. On/Off Switch: Turns the input power to the machine ON/OFF.

5. Shield Gas Outlet: Connect a gas hose from here to the shield

gas inlet on the torch.

6. Nozzle Lead Connection: Connect a #6 AWG cable from here

to pilot connection in FlexStart

®

console.

7. Work Lead Connection: Connect a 1/0 AWG cable from here to

cutting table.

8. Electrode Lead Connection: Connect a 1/0 AWG cable from

here to electrode connection in the FlexStart

®

console.

9. ArcLink Connector (5 Pin): Provides power and commu-

nication to the FlexStart

®

console.

10. Plasma Gas Outlet: Connect gas hose from here to 2-Gang

plasma gas inlet.

11. Purge: Allows the user to enable airflow from the machine for

both plasma and shielding gas.

12. Shield Gas Regulator: Allows the regulation of the shield

air/gas pressure.

13. Plasma Gas Regulator: Allows the regulation of the plasma

air/gas pressure.

FIGURE B.2

14. Shielding Gas Inlet (optional): Allows ability for independent

air/gas to be connected for shield .

15. Plasma Gas Inlet: Compressed air or gas connection.

16. 115V/10A Auxiliary Power Receptacle.

17. 10 Amp Circuit Breaker (CB-2): Protects the 115V Auxiliary

Power Receptacle.

18. Ethernet Connector (RJ-45): Used for ArcLink® XT commu-

nication.

19. 10 Amp Circuit Breaker (CB-2): Protects the 40V ArcLink

Power Supply

20. ArcLink Connector (5 Pin): Provides power and commu-

nication to the FLEXCOOL cooler.

21. Analog Terminal Strip (optional): Provides additional input

controls for corner current reduction, hold, and remote poten-

tiometer control.

22. 14-Pin CNC Interface: Allows access to Arc Start Trigger, Arc

Initiated contact, raw or divided voltage Arc Voltage, and

Forced Mark.

23. Reconnect Panel Access: Allows the unit to be configured for

380/400/415, 460, or 575 VAC input.

24. Input Cord Strain Relief: Used to connect the unit to input

power.

1

2

3

4

5

6

7

13

12

11

10

9

8

14

15

16

17

18

19

20

21

22

23

24

FlexCut

®

200 CE

OPERATION

CASE FRONT CONTROLS CASE BACK CONTROLS