Do you have a question about the Lincoln Electric SQUARE WAVE TIG 175 and is the answer not in the manual?

Provides detailed technical data for the welding machine.

Guidance on choosing a location, lifting, environmental factors, and preparing the area.

Details on connecting the welder to the power supply and voltage reconnection.

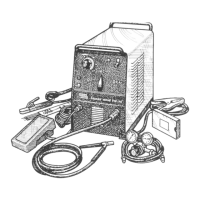

Connecting TIG torch, stick electrode holder, and work cables.

Essential safety rules, product description, and welding capabilities.

Detailed explanation of all front panel controls and their functions.

Step-by-step instructions for TIG and Stick welding, remote control use, and process guidance.

Options for machine mobility and remote current adjustment.

Various TIG torch models, adapters, parts kits, and filler metals.

Information on the included stick electrode holder and cable.

Critical safety warnings before performing any maintenance procedures.

Steps for cleaning internal components and inspecting cables and hoses.

Instructions on navigating and utilizing the troubleshooting section effectively.

Identifies and resolves issues related to machine output, fan operation, and no response.

Addresses common problems and solutions specific to TIG and Stick welding operations.

Electrical schematic for the SQUARE WAVE TIG 175, Code 11691.

Electrical schematic for the SQUARE WAVE TIG 175, Code 11826.

| Input Phase | Single Phase |

|---|---|

| Input Frequency | 60 Hz |

| Rated Output | 175 A |

| Output Range | 5 - 175 A |

| Output Current Range | 5-175A |

| Processes | TIG, Stick |

| TIG Welding Capability | Yes |

| Input Voltage | 230 V |

Loading...

Loading...