Do you have a question about the Lincoln Electric SQUARE WAVE TIG 255 and is the answer not in the manual?

General safety warnings including Proposition 65 and arc welding hazards.

Safety precautions specific to engine-powered equipment operation and maintenance.

Information on the potential dangers of electric and magnetic fields during welding.

Detailed safety measures to prevent electric shock while operating welding equipment.

Precautions to protect against arc rays, including eye and skin protection.

Safety guidelines for avoiding hazards associated with welding fumes and gases.

Safety measures to prevent fires and explosions caused by welding sparks and hot materials.

Precautions for the safe handling and use of compressed gas cylinders.

Safety guidelines for electrically powered equipment installation and grounding.

Detailed technical specifications for the Square Wave TIG 255, including input, output, and physical dimensions.

Recommended input wire and fuse sizes based on voltage and electrical code.

Essential safety precautions to be followed during the installation process.

Guidelines for choosing an appropriate location and understanding environmental protection ratings.

Procedures for proper machine grounding and minimizing high-frequency interference.

Instructions for connecting the input power supply to the machine.

Guidelines for connecting output cables, torch, and work leads.

How to connect the TIG torch to the welding output terminals.

Instructions for connecting the electrode cable for stick welding.

Important general warnings to be observed before operating the equipment.

Key safety instructions covering electric shock, fumes, sparks, and arc rays.

Explanation of graphic symbols used on the machine and in the manual.

Continuation of graphic symbol explanations for the welding machine.

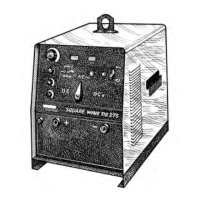

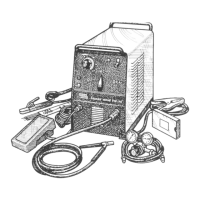

Overview of the Square Wave TIG 255, its features, recommended processes, controls, and design advantages.

Details on the machine's welding ratings, duty cycles, and known operational limitations.

Overview of the operator controls and detailed explanation of control panel keys.

Explanation of the different sections of the machine's display and what they show.

Identification and description of controls located on the front case of the machine.

How to use hand and foot amptrols for remote current control and arc starting.

Guidelines and considerations for performing TIG welding with the machine.

Step-by-step procedure for performing TIG welds using the 2-Step mode.

Step-by-step procedure for performing TIG welds using the 4-Step mode.

Detailed explanation of advanced TIG welding features like AC Wave Balance.

Information on the TIG Pulser feature, its settings, and operation.

Instructions for performing stick welding operations with the machine.

Details on auxiliary power outlets and the machine's overload protection system.

List of available optional accessories for the welding machine.

Information on the undercarriage and instructions for installing other accessories.

Safety warnings and precautions to be observed before performing maintenance.

Procedures for routine cleaning and periodic maintenance of the welding machine.

An exploded view diagram showing the general assembly of the machine's components.

Instructions on how to effectively use the troubleshooting guide to diagnose and solve problems.

Troubleshooting steps for problems related to the machine's output.

Troubleshooting steps for issues related to specific functions or indicators.

Further troubleshooting steps for output-related problems like overheating.

Further troubleshooting steps for function-related issues like buzzing noise.

Troubleshooting for issues related to indicator lights and audible alerts.

Troubleshooting specific problems encountered during TIG welding operations.

Further troubleshooting for TIG welding issues like low output or weak high frequency.

Troubleshooting for TIG welding problems such as lack of high frequency or gas flow.

Troubleshooting specific problems encountered during stick welding operations.

Wiring diagram for specific model codes, illustrating internal connections.

Wiring diagram for different model codes, illustrating internal connections.

Details of the limited warranty provided by Lincoln Electric for the equipment, including coverage and period.

Procedures for obtaining warranty repair and associated costs.

Key limitations and exclusions applicable to the product warranty.

| Processes | TIG, Stick |

|---|---|

| TIG Welding Capability | Yes |

| Stick Welding Capability | Yes |

| Pulse TIG Welding | Yes |

| AC/DC Output | Yes |

| High Frequency Start | Yes |

| Lift Arc Start | Yes |

| Input Frequency | 60 Hz |

Loading...

Loading...