Do you have a question about the Lincoln Electric SQUARE WAVE TIG 255 IM520-B and is the answer not in the manual?

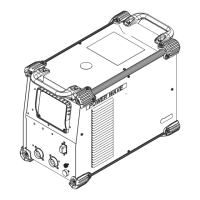

| Input Phase | Single Phase |

|---|---|

| Input Frequency | 50/60 Hz |

| Output Current Range (TIG) | 5 - 255 A |

| Output Current Range (Stick) | 20 - 255 A |

| Open Circuit Voltage | 80V |

| TIG Welding Capability | Yes |

| Stick Welding Capability | Yes |

| Pulse Welding Capability | Yes |

| AC/DC Output | Yes |

| High Frequency Start | Yes |

| Lift Arc Start | Yes |

| AC Frequency | 20 - 250 Hz |

| Input Voltage | 230/460 V |

Discusses potential health risks associated with electric and magnetic fields generated during welding.

Details the severe risks of electric shock, emphasizing protective measures and insulation.

Covers the dangers of arc rays and the necessary eye, skin, and helper protection.

Highlights hazards from welding fumes and gases, recommending ventilation and respiratory protection.

Warns about welding sparks causing fires and explosions, advising fire prevention.

Crucial safety guidelines for qualified personnel during machine installation.

Details machine grounding and measures to mitigate high frequency interference.

Overarching safety warnings including shock, fumes, sparks, and arc rays.

Critical safety measures to follow before and during maintenance procedures.

Steps for cleaning, inspecting, and maintaining the machine for optimal performance.

Instructions on how to effectively use the troubleshooting section to diagnose issues.

Addresses symptoms like complete machine failure, no fan, or no displays.

Explains symptoms related to overheating, thermostat activation, and cooling issues.

Loading...

Loading...