Do you have a question about the Lincoln Ranger 250 and is the answer not in the manual?

Warnings about chemicals in engine exhaust known to cause cancer or reproductive harm.

General warnings about the dangers of arc welding and protective measures.

Information on potential interference of EMF fields with pacemakers and health effects.

Details on preventing electric shock, including insulation and wet conditions.

Guidance on protecting eyes and skin from arc rays using proper shielding and clothing.

Warnings about hazardous fumes and gases produced during welding and ventilation needs.

Precautions to prevent fire and explosion caused by welding sparks and hot materials.

Guidelines for safe handling and storage of compressed gas cylinders.

Safety measures for electrically powered equipment, including grounding and wiring.

Detailed technical data for the Ranger® 250 welder, including engine, output, and dimensions.

Details on available receptacles and circuit breaker ratings for auxiliary power.

Critical safety guidelines for installing and operating the welder, covering electrical, engine, and physical hazards.

Guidelines for safely towing and mounting the welder onto vehicles.

Instructions for checking engine oil, fuel, and battery before initial operation.

Installation details for the muffler, spark arrester, and high frequency TIG components.

Connecting remote controls and understanding machine grounding requirements.

Connecting welding output cables to terminals and proper cable sizing and installation.

Information on auxiliary power receptacles and setting up standby power connections.

Electrical diagram and safety warnings for connecting the welder to premises wiring.

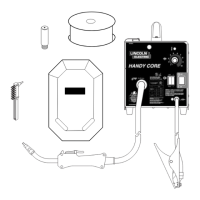

Step-by-step guide for connecting various wire feeders to the Ranger® 250.

Steps to connect LN-742, K487-25 Spool Gun, and Cobramatic to the Ranger® 250.

Essential safety guidelines to follow before and during machine operation.

Overview of the Ranger® 250's capabilities and key design elements.

Procedures for starting the engine, adding fuel, and related safety warnings.

Explanation of the primary welding controls: Output, Mode Selector, and Arc Control.

Detailed description of all operator controls, connectors, and engine control switches.

Step-by-step instructions for starting and stopping the engine safely.

Explanation of CC-Stick and Downhill Pipe welding modes and their settings.

Information on duty cycle definition and typical fuel consumption rates for different operating conditions.

Guidelines for DC TIG welding, including Touch Start and use of TIG modules.

Procedures for MIG and flux-cored wire welding using the CV-WIRE mode.

Instructions for arc gouging and details on the auxiliary power output and its limitations.

Guidance on using welding and auxiliary power simultaneously and selecting appropriate extension cords.

Safety guidelines for performing maintenance on the machine and engine.

Daily and periodic maintenance tasks for Kohler and Subaru Robin engines.

Procedures for changing engine oil, refilling capacities, and servicing the oil filter.

Instructions for cleaning and maintaining the air cleaner and pre-cleaner elements.

Maintenance procedures for the air filter paper element and spark plug.

Procedures for servicing the fuel filter, engine adjustments, and battery care.

Steps for cleaning the battery, checking electrolyte, and proper charging procedures.

Guidelines for storing, cleaning, and servicing the welder and generator components.

Instructions on how to effectively use the troubleshooting section to diagnose and resolve issues.

Troubleshooting common engine starting problems and battery charging issues.

Diagnosing problems related to engine idle speed and lack of full power output.

Troubleshooting issues with welding power output, control, wire feeder, and auxiliary power.

Addressing problems with a cold, unstable, or unsatisfactory welding arc.

Detailed wiring diagram for the Ranger 250G model.

Diagram showing connection of LN-25 to K857 remote control.

Diagram showing connection of LN-25 to K444-1 remote control.

Diagram for connecting LN-25 with K624-1 42 volt remote output control module.

Wiring diagram for connecting the LN-7 wire feeder.

Wiring diagram for connecting the LN-742 wire feeder.

Wiring diagram for connecting the LN-8 wire feeder.

Diagram for connecting engine welders to K867 control cable adapter.

Diagram for connecting spool guns (K691-10, K488, K487) to the engine welder.

Wiring diagram for connecting the K930 TIG Module.

Wiring diagram for connecting the K1587-1 Cobramatic wire feeder.

Drawings showing the physical dimensions and mounting hole locations of the Ranger® 250.

| Fuel Capacity | 12.5 Gallons |

|---|---|

| Processes | Stick, TIG, MIG, Flux-Cored |

| Power Source | Engine Driven |

| Auxiliary Power | 10, 000 Watts |

| Open Circuit Voltage | 80V |

| Rated Output | 250A AC/DC at 25V, 100% Duty Cycle |

Loading...

Loading...