Do you have a question about the Lincoln LN-25 PRO and is the answer not in the manual?

Inspect shipment for immediate damage upon receipt.

Read and understand manual and safety precautions for safe operation.

Protect yourself and others with appropriate safety gear.

Address specific hazardous conditions and materials.

State warnings regarding diesel and gasoline engine exhaust constituents.

General hazards and precautions for arc welding.

Safety measures specific to engine-driven equipment.

Hazards and precautions related to EMF fields.

Warnings and precautions regarding electric shock.

Protection against burns from arc rays.

Dangers of welding fumes and gases.

Preventing fires and explosions from welding sparks.

Precautions for handling compressed gas cylinders.

Safety considerations for electrically powered units.

CE mark conformity and EM emissions overview.

User responsibility for installation and managing disturbances.

Evaluating the surrounding area for potential EMC issues.

Connecting to mains and shielding supply cables.

Routine maintenance and cable management for EMC.

Equipotential bonding and workpiece earthing for EMC.

Key technical data including voltage, current, duty cycle, and dimensions.

Electrical shock warnings and safe installation practices.

Proper placement for optimal performance and safety.

Avoiding interference with RF controlled equipment.

Recommended cable sizes based on amperage and duty cycle.

Procedure for connecting shielding gas supply.

Steps for setting up the wire drive system.

How to replace the gun bushing and related parts.

Procedure for installing drive rolls and guides.

Instructions for loading wire spools onto the feeder.

Adjusting the pressure arm for optimal wire feeding.

Connecting the welding gun to the wire feeder.

Diagrams for connecting to CC power sources.

Diagrams for connecting to CV power sources.

Wiring diagrams for CV sources without remote/local switch.

Wiring diagrams for CV sources with Twist-Mate and remote/local switch.

Wiring diagrams for CV sources with Twist-Mate, no remote/local.

Critical safety warnings before operating the machine.

Explanation of symbols used on the machine and in the manual.

Definitions of common welding terms.

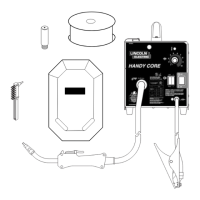

Overview of the LN-25 PRO's features and capabilities.

Suitable welding processes and limitations.

List of compatible power sources.

Identification and function of controls on the front panel.

How to set parameters for CV operation.

Adjusting WFS for CC power sources.

Guidelines for welding with CC power sources.

Using the WFS knob and range switch.

Connecting and using the gun trigger and work sense lead.

Understanding the Thermal and Polarity LEDs.

Identification of internal switches and components.

Functions of trigger modes and CV/CC settings.

Adjusting spool retainer and brake.

Using the cold feed feature for wire threading.

Function of the gas purge button.

Description of pre-installed accessories.

Types of drive roll kits available for different wire types.

Details on timer kits and coaxial power cables.

Information on work and feeder cable packages.

Accessories for power source connection and grounding.

Various gun receiver bushings for different gun types.

Adapters for spools and water connection kits.

Gas regulators and wire feed speed meters.

Critical safety warnings before performing maintenance.

Tasks for regular and periodic upkeep.

Procedure to verify and adjust the analog voltmeter.

Steps to calibrate the wire feed speed mechanism.

Instructions for navigating the troubleshooting section.

Diagnosing digital display error codes and motor issues.

Troubleshooting power-up issues and display absence.

Diagnosing output problems and gas flow failures.

Addressing issues with inconsistent wire feed.

Troubleshooting incorrect or stuck wire feed speeds.

Diagnosing and fixing an unstable or hunting arc.

Resolving issues with arc starts and bead appearance.

Schematic of the unit's electrical wiring.

Physical dimensions and measurements of the unit.

Information on Lincoln Electric's customer support and advice policy.

| Output Current Range | 30-250A |

|---|---|

| Processes | MIG, Flux-Cored |

| Wire Feed Speed Range | 50-700 IPM |

| Wire Size Range | 0.023-0.045 in (0.6-1.2 mm) |

| Input Current at Rated Output | 20A |

| Output Range | 30-250A |

Loading...

Loading...