Add 15-20 Drops

Smoke Fluid

! Remove the side rods (the rods that connect each drive wheel to the other) from

the wheels in order to slip the new tire over the grooved drive wheel. These bolts

can be loosened with a 5.5 mm nutdriver.

! Clean the groove using a cotton swab and denatured alcohol.

! Make sure the old tire has been completely removed from the groove in the drive

wheel, using a razor blade or small flathead screwdriver to pry away any remains.

! Clean the groove using a cotton swab and denatured alcohol.

! Slip the new tire onto the wheel. You may find it useful to use two small flathead

screwdrivers to stretch the tire over the wheel.

! If you twist the tire while stretching it over the wheel, you will need to remove and

reinstall the tire. Otherwise your engine will wobble while operating.

! Make sure the tire is fully seated inside the groove. Use a razor blade to trim away

any excess tire that doesn't seat itself inside the groove properly.

STEP

2

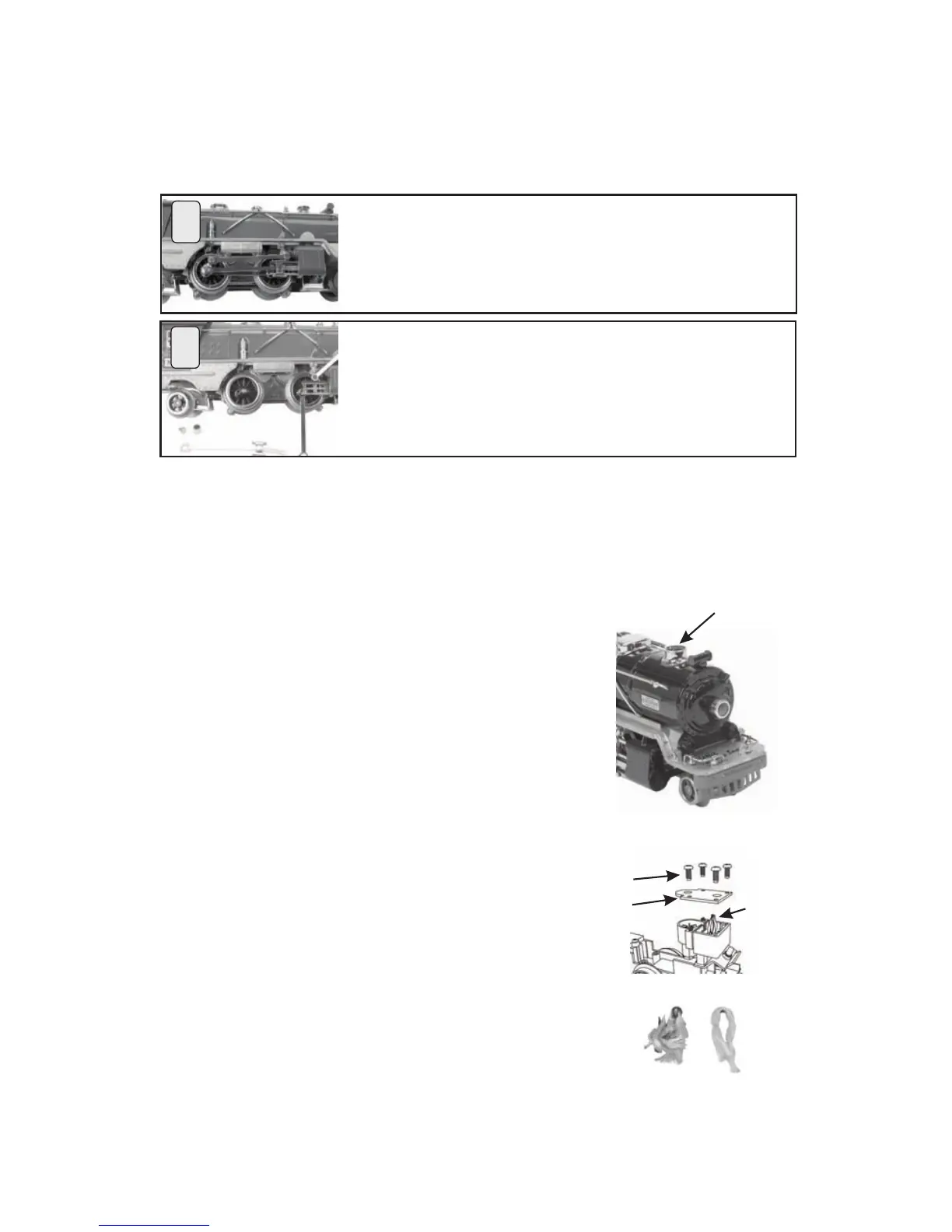

Smoke Unit Cover

Wick in

Poor

Condition

Wick in

Good

Condition

Traction Tire Replacement Instructions

Your locomotive is equipped with two neoprene rubber traction tires on the rear set

of flanged drivers. While these tires are extremely durable, they may occasionally

need to be replaced.

ProtoSmoke™ Unit Operation

This steam locomotive contains a smoke unit that outputs smoke through the

smokestack on the boiler of the engine. The smoke unit is essentially a small

heating element and wick that soaks up and then heats a mineral

oil-based fluid that emits a harmless smoke. The smoke is then

forced out of the stack by a small electric fan.

With a few easy maintenance steps, you should enjoy

trouble-free smoke unit operation for years.

! When preparing to run this engine, add 15-

20 drops of smoke fluid through the

smokestack. We recommend M.T.H.

ProtoSmoke fluid (a small pipette of

ProtoSmoke fluid is included). Do not

overfill the unit or the fluid may leak out

and coat the interior engine components.

! If you choose not to add the fluid (or have

already added the fluid but choose to run

smoke-free), turn off the smoke unit control

(Full Counter Clockwise Position) located

under the tender body. Failure either to

add fluid to the unit or to turn it off may

damage the smoke unit heating element

and/or wicking material.

! When the smoke output while running the

engine begins to diminish, add another 10-15

drops of smoke fluid or turn the smoke unit off.

! When storing the unit for long periods of

time, you may want to add about 15 drops of

fluid to prevent the wick from drying out.

STEP

1

Lionel Corporation No. 255, 260 & 263 Steam Engines with Proto-Sound® 3.0

35

Fig. 14: Adding Fluid

Inspection

Cover

Screws

Inspection

Cover

Wick

Loading...

Loading...