Auxiliary roll gauge settings

A. Type “S” Double Seam: (22-26 Gauge) 5/16” Pocket. Uses approximately 1” material.

Gauge setting……………1-1/8”

B. Type “L” Double Seam: (16-20 Gauge) 7/16” Pocket. Uses approximately 1-1/8” material.

Gauge setting…………….1-5/16”

C. Standing Seam Rolls: (16-20 Gauge) 3/4” Height. Uses approximately 2-1/8” per completed

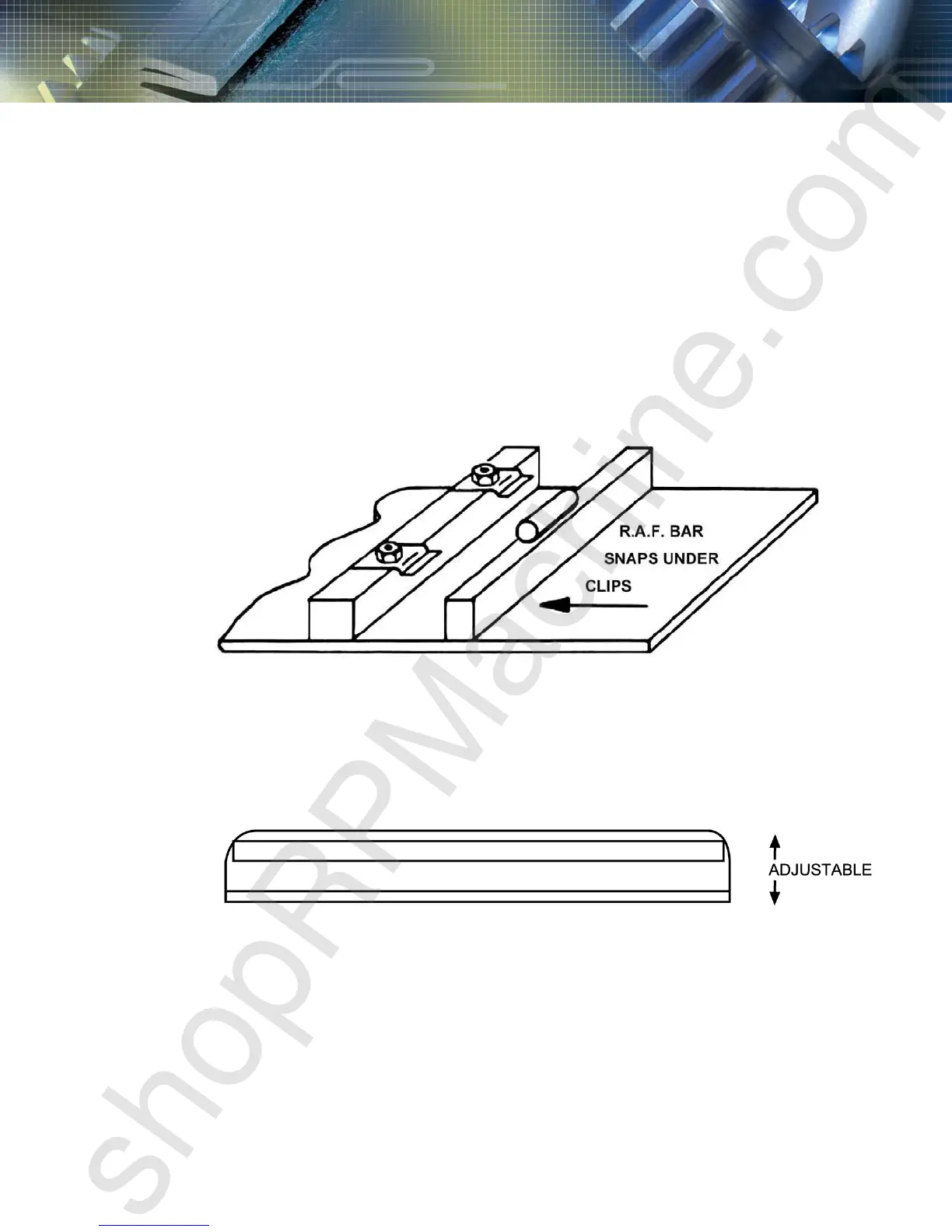

seam. Forms both single and double edge by simple gauge attachment. Note: Two piece

entrance gauge supplied. Drilled bar mounted to stand with clips attached, to form standing

seam.

Gauge setting……………... 2”

Second Gauge edge bar snaps under clips and is used for right angle flange.

See Sketch below: (2)

SKETCH No. 2

The top seven roll is not fastened by bolt and washer but allowed to float.

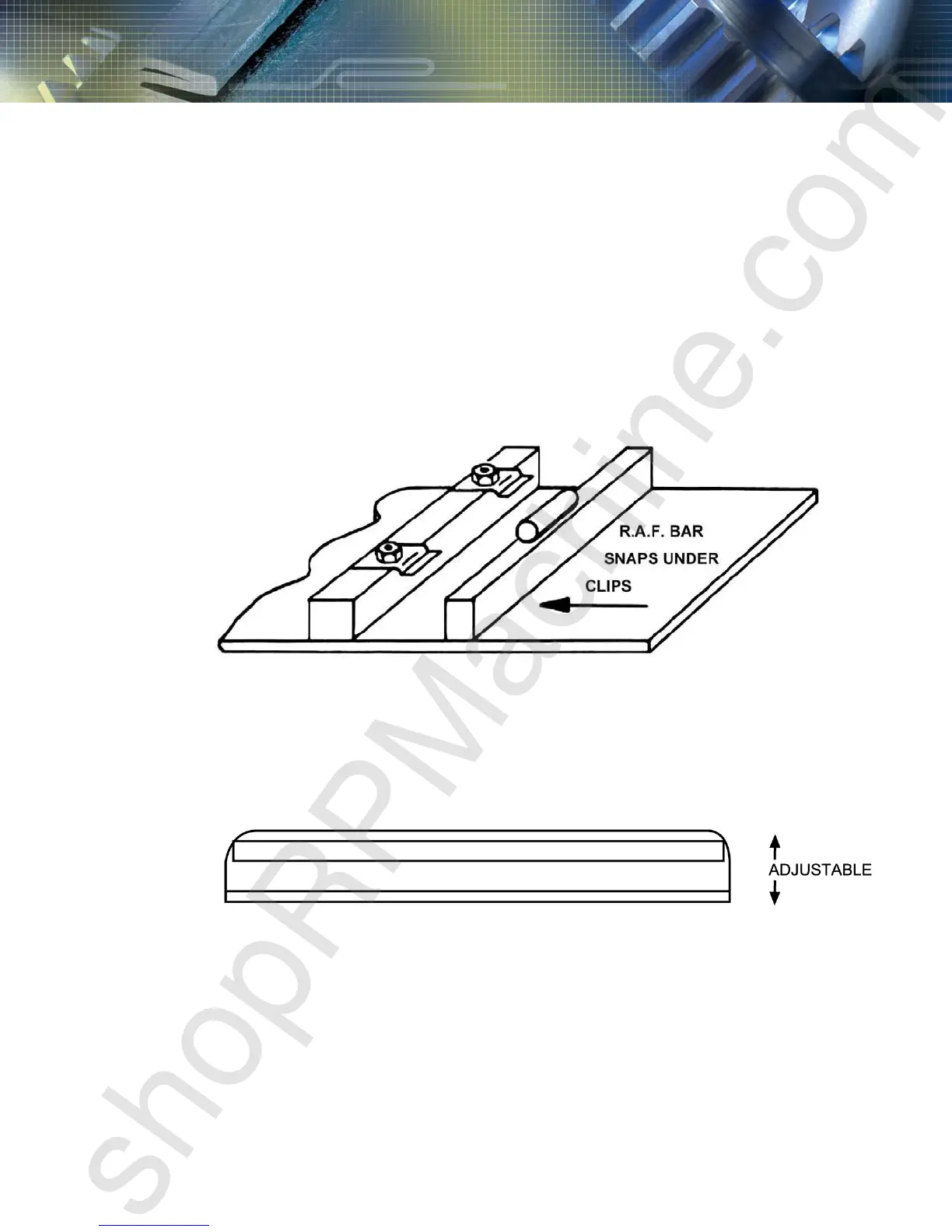

The exit angle gauge has an adjustable bar that can be lowered to exert pressure on the

material as it emerges from the rolls, thereby straightening the finished section.

See Sketch (3) below: Set exit gauge to the standing seam shape.

SKETCH No. 3

D. Right Angle Flange Rolls: (16-24 Gauge) on straight pieces only. Adjustable to 7/16” high.

Gauge setting……………….1-5/16”

E. 5/16” Pittsburgh Lock Rolls: (22-26 Gauge) 5/16” Pocket.

Gauge setting………………..1-11/16”

To install auxiliary opening roll holder remove rolls, from the number six roll station and bolts

that straddle bottom six roll shaft (See Sketch 4 and 4A). Place opening roll holder onto

machine and fasten with the two ½”-13 NC x 2” HHCS provided.

LKF Pittsburgh 16 Gauge

shopRPMachine.com

Loading...

Loading...