5

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 Toll Free 1 800 331 6232 www.logangraphic.com

Instruction Manual

Model F300-1

Studio Joiner

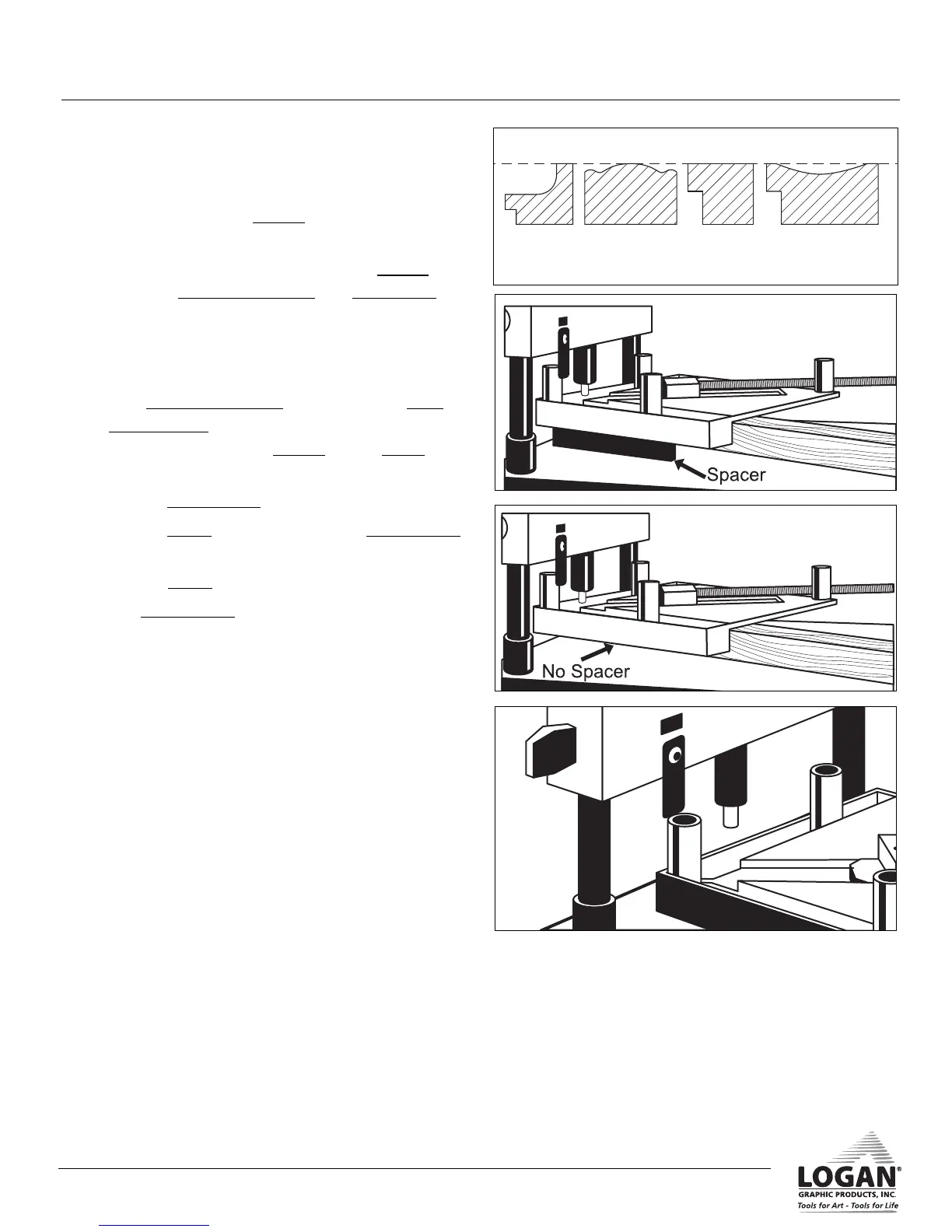

Horizontal Plane

Spacer

Needed

Spacer

Needed

No Spacer

Needed

No Spacer

Needed

Fig. 10

Preparation continued

C. Moulding Spacer

1. Moulding must have support for V-nail to drive

into wood. Use the spacer when moulding is

not even with horizontal plane (Fig. 10).

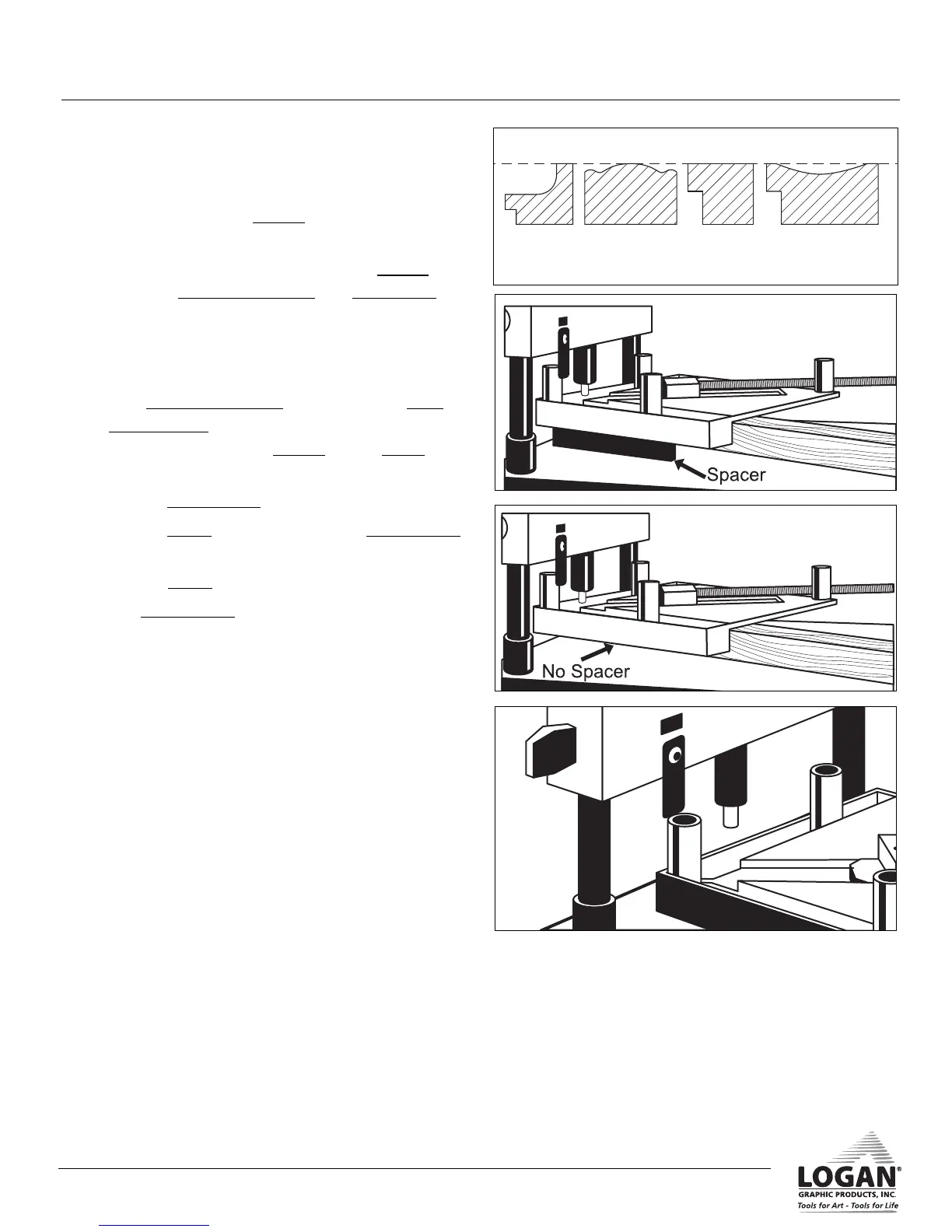

2. With rubber edges facing up, place spacer

between clamped moulding and base board

(Fig. 11).

D. Adjust Beam Height

1. Turn clamped moulding over and lay on base

board spacer (Fig. 12). If using spacer, position

clamped moulding on spacer where V-nail is to

be pressed in.

2. Line up depth gauge with vise post.

3. Loosen knobs and adjust beam so depth gauge

lightly touches vise post (Fig. 13).

4. Tighten knobs.

5. The depth gauge may be pivoted either to

left or right to gain extra clearance.

L956NStudio Joiner manual R1_08.qxd:Studio Joiner 1_4_05.qxd 1/4/10 11:17 AM Page 6

Loading...

Loading...