5.

5.

5.

5. Maintenance

Maintenance

Maintenance

Maintenance and

and

and

and repair

repair

repair

repair

•

•

•

•

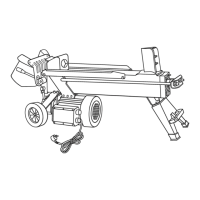

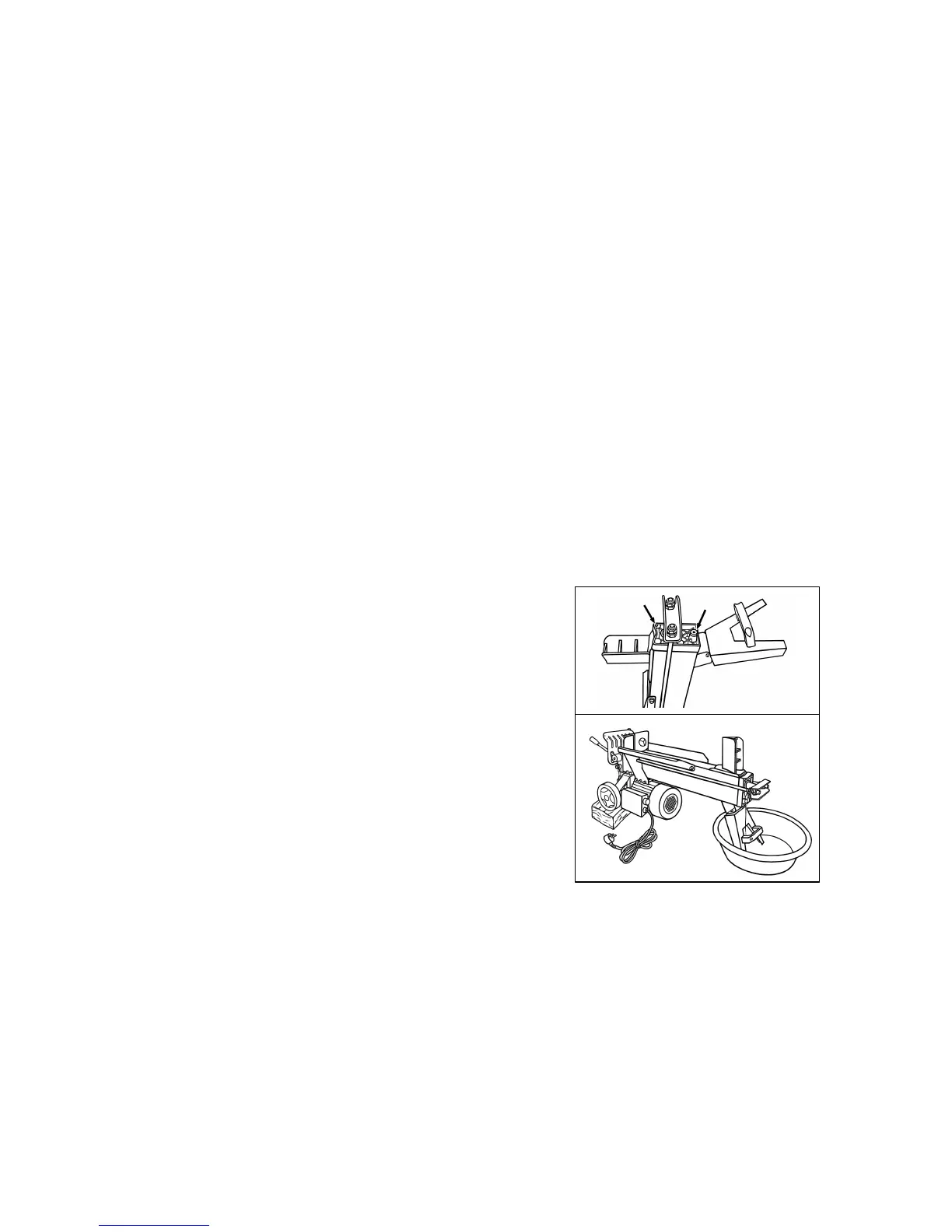

Refer to the Components drawing and parts list should it become necessary to disassemble the unit for

repair

or

replacement of parts.

NOTE:

a)

Ensure the power cable

is

unplugged while performing any maintenance and repair.

b) The hydraulic system

is

preset at the factory. Don ’ t adjust the valve.

c) Never alter this machine in any manner under any circumstances. Any alteration circumventing the design

capabilities and capacities of this machine could result in serious injury and will void the warranty.

d) Replace all damaged and worn parts immediately with original equipment and manufacturer ’

s

parts

only.

e) Wipe unit with an oiled rag to prevent rust. If the wedge becomes dull

or

nicked, it can be sharpened.

Wear safety gloves while handling the wedge.

f) Never check for leaks of hydraulic fluid with your hand. Escaping fluid under pressure can have sufficient

force to penetrate skin causing serious personal injury

or

even death. Leaks can be detected by passing a

piece of cardboard over the suspected leak and looking for discoloration.

g) Never loosen

or

remove hydraulic fittings

or

the cap of hydraulic tank while the log splitter

is

running.

h) If the motor i

s

overload for a long time, the thermal protector in it which operating temperature

is

1 30 ° C will disconnect the power of motor. Switch off and unplug the power cable, cool down the motor for

half an hour and it will connect again for continual operation. If not, i t ’

s

necessary for you to call your dealer

for customer support.

i)

The troubles of hydraulic system and motor other than described above should only be handled by

qualified specialists.

j) Periodically check the oil level in the hydraulic reservoir. If there ’

s

a slow

or

erratic ram running during

operation, it indicates the problem of oil shortage

or

excessive air in the reservoir.

T

o solve this problem,

please refer to the following Term

5.

l).

k) After each season use, check if the hydraulic oil need to change. Generally, this log splitter has oil filter in

the tank, so just change the oil when there ’

s

abnormal louder noise

or

ram block during operation.

T

o solve

this problem, please refer to the following T erm

5.

l).

l) Directions:

Directions:

Directions:

Directions: how

how

how

how to

to

to

to changing

changing

changing

changing hydraulic

hydraulic

hydraulic

hydraulic oil,

oil,

oil,

oil, fill

fill

fill

fill the

the

the

the hydraulic

hydraulic

hydraulic

hydraulic reservoir

reservoir

reservoir

reservoir and

and

and

and repel

repel

repel

repel the

the

the

the excessive

excessive

excessive

excessive air

air

air

air in

in

in

in

the

the

the

the reservoir.

reservoir.

reservoir.

reservoir.

Note: The hydraulic tank

is

shipped with 10W AW hydraulic fluid. If it

is

difficult to obtain, Dexron Ⅲ

automatic transmission fluid can be substituted. You must drain the system. Don ’ t mix Dextron and 10W

hydraulic fluid. Use only clean oil and take care to prevent dirt from entering the hydraulic reservoir.

6.

6.

6.

6.

Storage

Storage

Storage

Storage

NOTE:

a)

Store this unit switched off and unplugged.

b) Allow machine to cool 5 minutes after every use before storing.

c) Protect power supply cable from heat, sunshine, aggressive liquids and sharp edges.

d)

Store unit in a clean, dry area. Don ’ t store it unprotected outdoors, next to corrosive materials

or

in damp

environment .

e) Store this splitter where children can ’ t start it.

9

9

9

9

•

Loading...

Loading...