Instructions for use Lojer Modux nursing bed / Version 2.5

Copyright © Lojer Oy, 2022 47

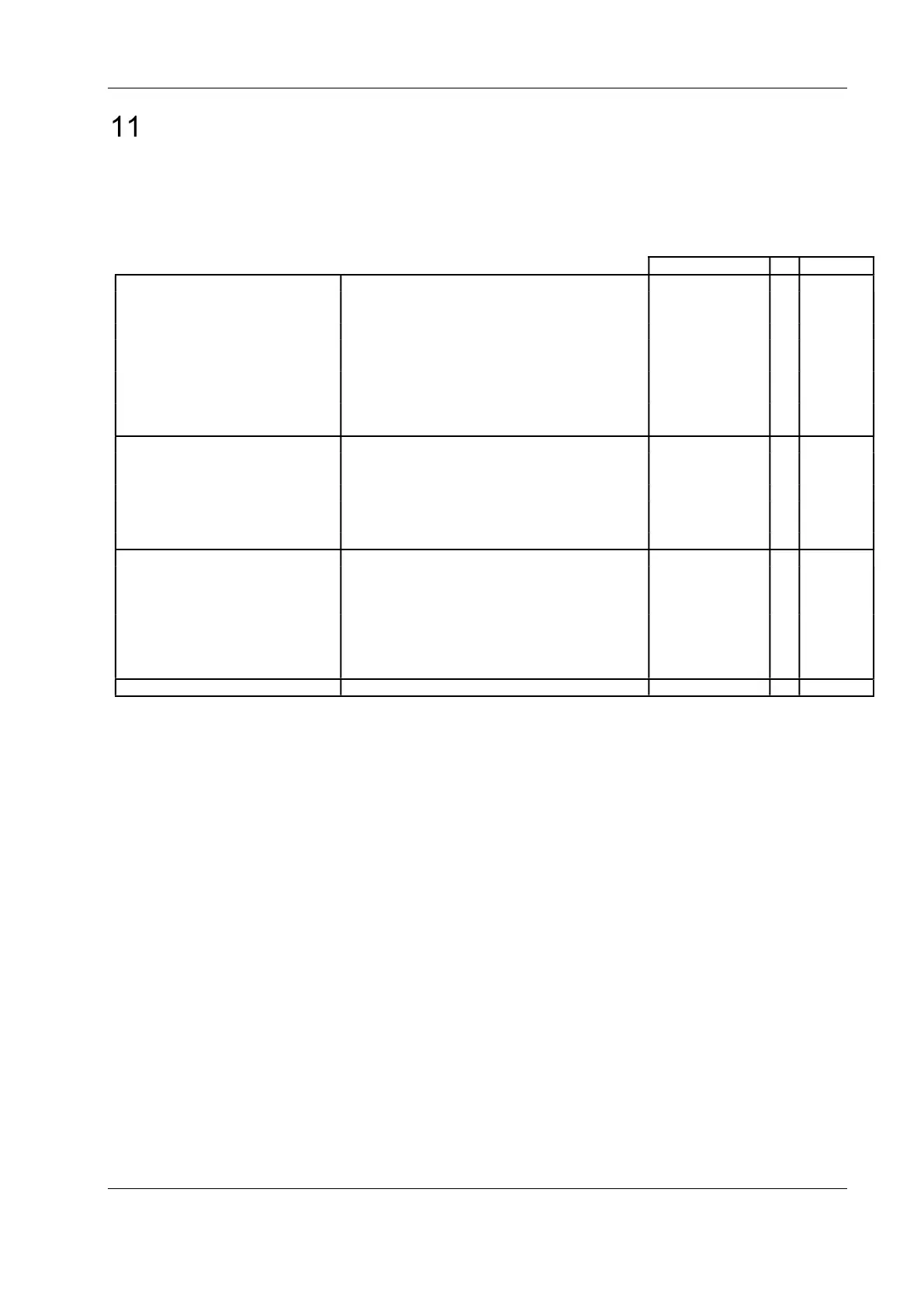

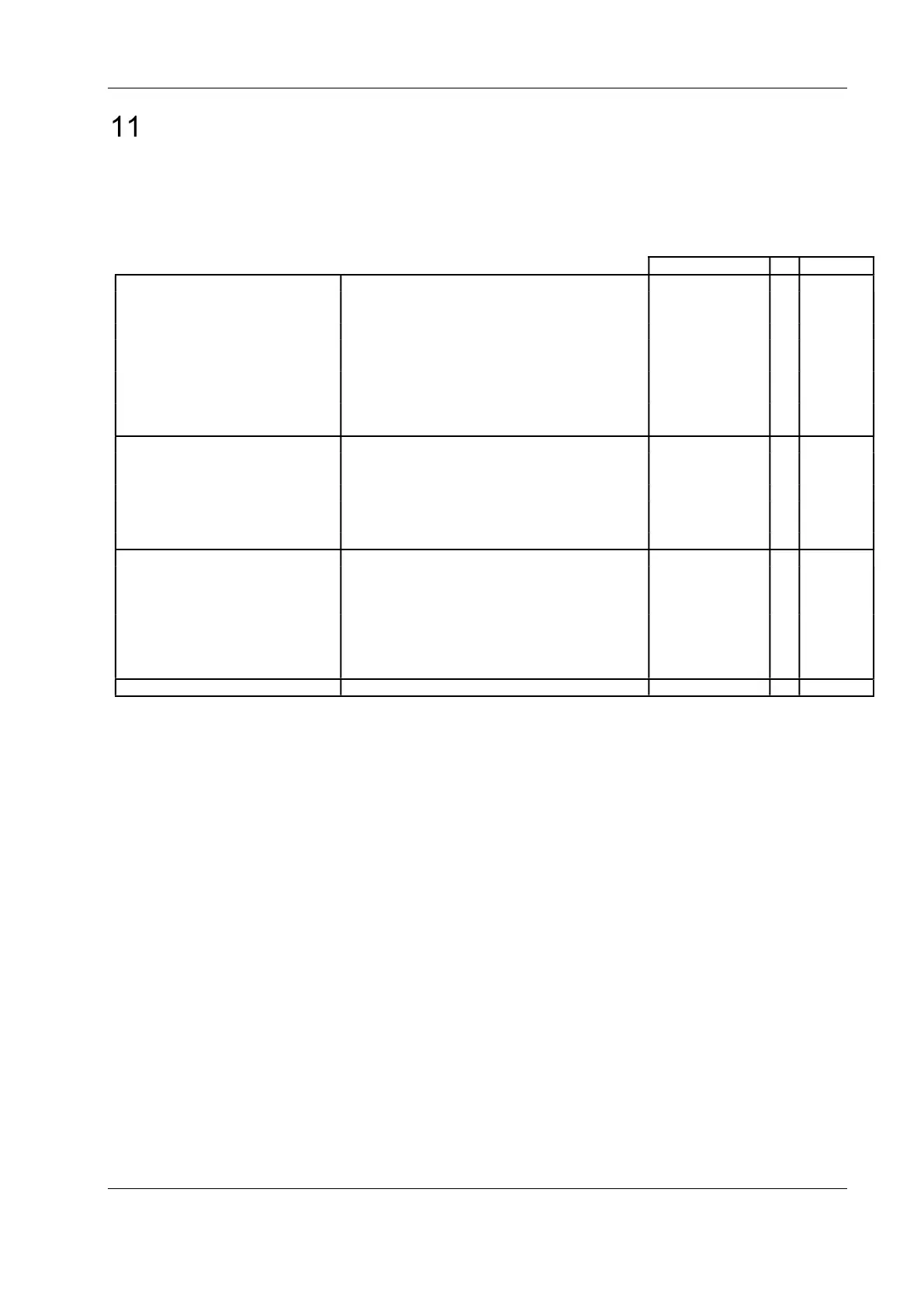

Inspection form

ANNUAL INSPECTION / ANNUAL MAINTENANCE PROCEDURES

SERVICE TECHNICIAN AND DATE:

________________________________________

________________________________________

________________________________________

ELECTRICAL CLASS OF THE

MOUNTING POINTS FOR ACCESSORIES

MAINTENANCE AND INSPECTION:

FOLDING MECHANISM STRUCTURES

CLEANING/WASHING OF STRUCTURES

NURSE CONTROL PANEL (optional)

TRENDELENBURG (hospital beds)

BATTERY CHARGE (optional)

ELECTRICAL SAFETY MEASUREMENTS

ACCESSORIES, LIFT SUPPORT, ETC.

POSSIBLE DAMAGE; FRACTURES, DEFORMATIONS, SIGNS OF UNUSUAL WEAR

: FRACTURES, FASTENINGS FOR CORDS

SIGNS OF WEAR OR ABRASION ON COMPONENTS OR CORDS.

C) CHECK THAT THE PEG LOCKING RINGS AND C

FASTENINGS AND THE FASTENINGS OF ALL COMPONENTS, TOLERANCES AND MECHANISMS IN GENERAL.

D) LUBRICATE MECHANISM JOINTS, BEARINGS AND SLIDING SURFACES, LIFTING MECHANISM JOINTS, LOWER FRAME

ROCKER PIPE BEARINGS. STRUT BAR JOINTS AND BRAKE LEVER JO

INTS, SIDERAIL MECHANISM IN BED END.

FUNCTIONAL TESTING, STOPPING IN THE EXTREME POSITIONS, ALSO UNDER LOAD,

FUNCTIONAL TESTING OF THE

HELD CONTROLLER AND THE NURSE CONTROL PANEL.

F) CHECK THE HOLD OF ALL WHEEL BRAKES, THE LOCKING OF THE

DIRECTION WHEEL IN THE TRANSPORT POSITION

THE GENERAL CONDITION OF THE WHEELS, OPERATION OF THE BRAKE PEDAL AND BRAKES ETC.

G) CHECK THE FUNCTIONALITY OF THE ADJUSTMENTS, CONDITION AND HOLD OF GAS SPRINGS.

TOP POSITION, SPACE UNDER LOWER RAIL, LUBRICATE LOCKS, SLIDING

PARTS, JOINTS IF NECESSARY. CHECK THE CONDITION IN GENERAL; FRACTURES, CRACKS, FASTENINGS

I) SUITABLE LUBRICANT E.G. WURTH HS 2000 SYNTHETIC SPRAY VASELINE OR SIMILAR

K) PERFORM AN ANNUAL ELECTRICAL SAFETY MEASUREMENT FOR CLASS I DEVICES, ALSO RECOMMENDED FOR

CLASS II DEVICES. PERFORM THE MEASUREMENT WHEN REPLACING POWER CORDS OR ELECTRICAL COMPONENTS

E.G CONTROL UNIT OR WHEN DISCONNECTING PROTECTIVE EARTH WIRINGS (CLASS I PRODUCTS).

MORE INFORMATION ON ELECTRICAL SAFETY MEASUREMENTS IN STANDARD EN 62353.

L) REPLACE DEFECTIVE COMPONENT, MAKE NOTIFICATIONS IF NEC

ESSARY FOR PARTS UNDER WARRANTY

X) WHEN CHECKING THE CONDITION OF MOTORS, PARTICULAR ATTENTION SHOULD BE PAID

AND SPECIAL ATTENTION IN INSPECTIONS WHEN FOLLOWING CRITERIA OR CASES:

IF LOAD ON THE BED HAS BEEN SIGNIFICANT, I.E. CONTINIUS LOAD HAS BEEN CLOSE SWL OR MAX. PATIE

IF BED IS RAISED MORE THAN 3,000 CYCLES PER YEAR

WHEN TESTING THE FUNCTIONALITY OF THE MOTORS, LISTEN TO ANY UNUSUAL SOUNDS OR VIBRATIONS FROM

MOTORS OR MOTOR GEARBOX, SPINDEL ETC. REPLACE OR SERVICE WHEN NECESSARY

Z) RECORD ALL REQUIRED REPAIR WORK, PART REPLACEMENTS ETC.

CONDITION AND ATTACHMENT OF MARKING

AND WARNINGSTICKERS OF THE DEVICE AND ACCESSORIES.

Loading...

Loading...