17

GB

CHECKING THE FITTING

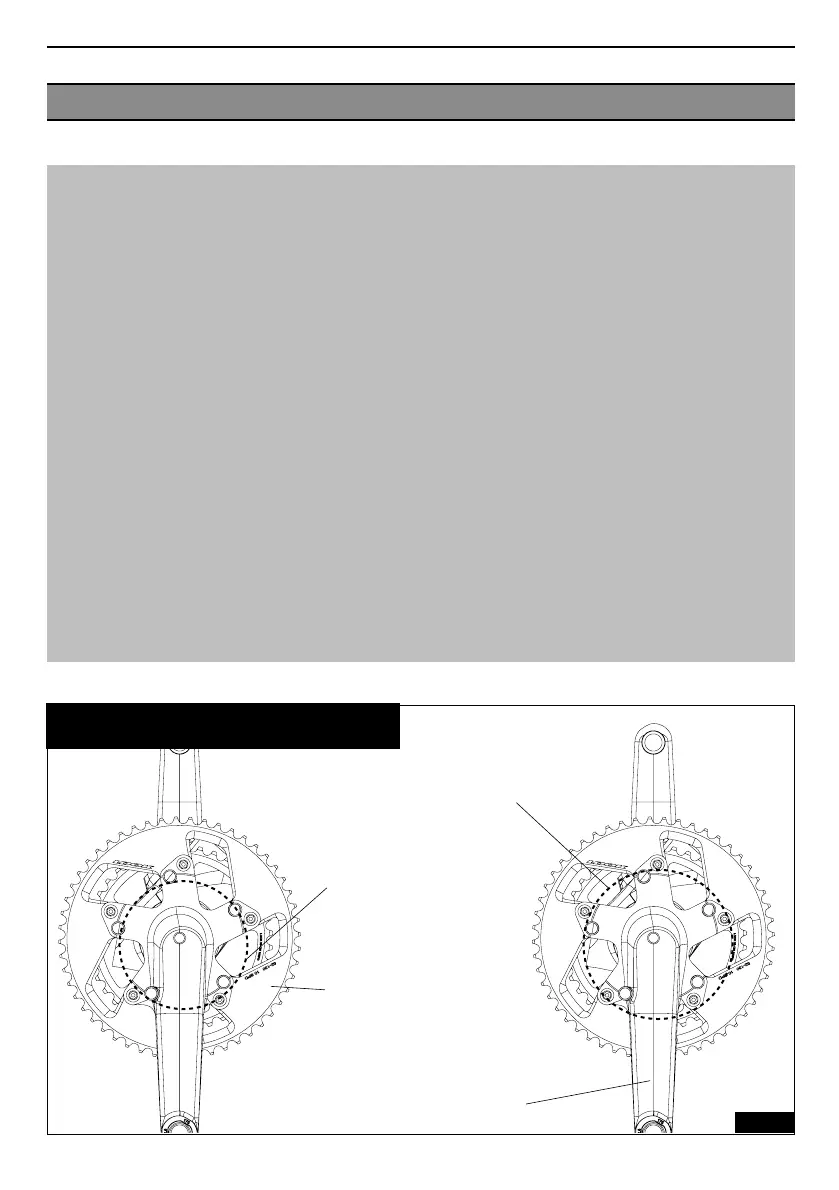

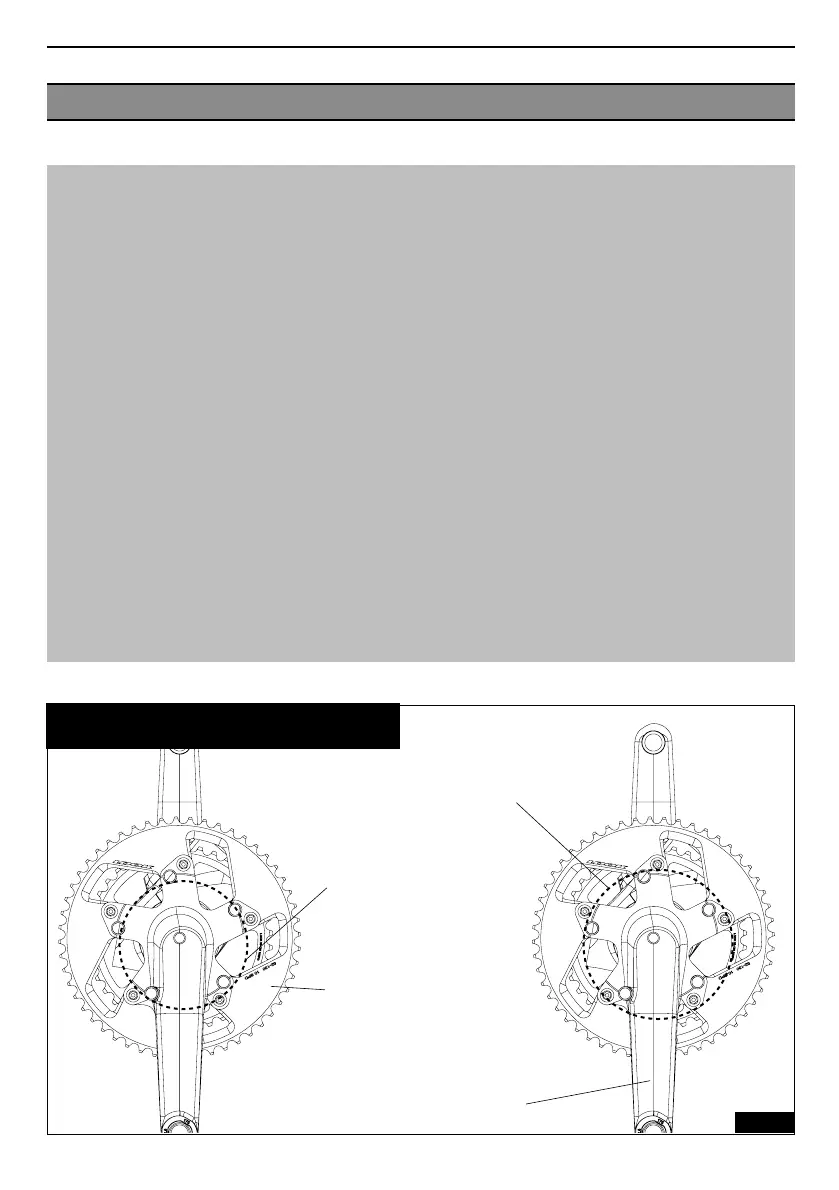

Fig 5

Chainring bolt holes spread out

over a 130mm-diameter circle

(the largest) for fitting double

chainrings.

Chainring bolt holes spread out

over a 110 mm-diameter circle

(the smallest) for fitting compact

chainrings.

The marking on the small

chainring should appear through

the large chainring.

The 2 markings should be

juxtaposed. This is the best

configuration for gear change.

Direction of the chainrings by

alignment of the chain securing

device behind the right-hand

crank.

Checking fitting of the chainrings:

When fitting the chainrings, check the following:

- The direction of the chainrings so that gears can be changed correctly for standard chainrings.

- That 130mm bolt patterns are placed on the outermost of the spider and 110mm bolt patterns are

placed on the innermost holes as shown in Figure 5.

- That the LOOK engravings are in the direction shown on figure 5 for LOOK specific chainrings.

- The position of the chain securing device on the outer chainring to prevent the chain from be-

coming stuck between the chainring and the crank. This chain securing device should be located

behind the crank.

- Torque of chain wheel attachment screws: 6 Nm.

IMPORTANT:

LOOK recommends use of its specific chainrings designed for the ZED 2 crank assembly for the fol-

lowing reasons:

- The specific shapes of the teeth of each LOOK chainring to facilitate gear change have been devel-

oped especially for fitting on the double and/or compact ZED 2 spider.

- The resistance and rigidity of LOOK chainrings have been optimised by providing a larger contact

surface at the attachment of each spoke.

Important: the following flange combinations are not recommended:

- 42 x 51 teeth

- 44 x 51 teeth

Loading...

Loading...