15

4.8 Wiring the Pump

The power wires on the pump are black with white

lettering to indicate L1, L2 and L3. WRITE DOWN the

colors that you splice to L1/ L2 / L3 so you can match

them with the L1/ L2 / L3 terminals in the pump control-

ler. If your pump cable has the standard GREY,

BROWN, BLACK and GREEN-YELLOW colors, use

this sequence:

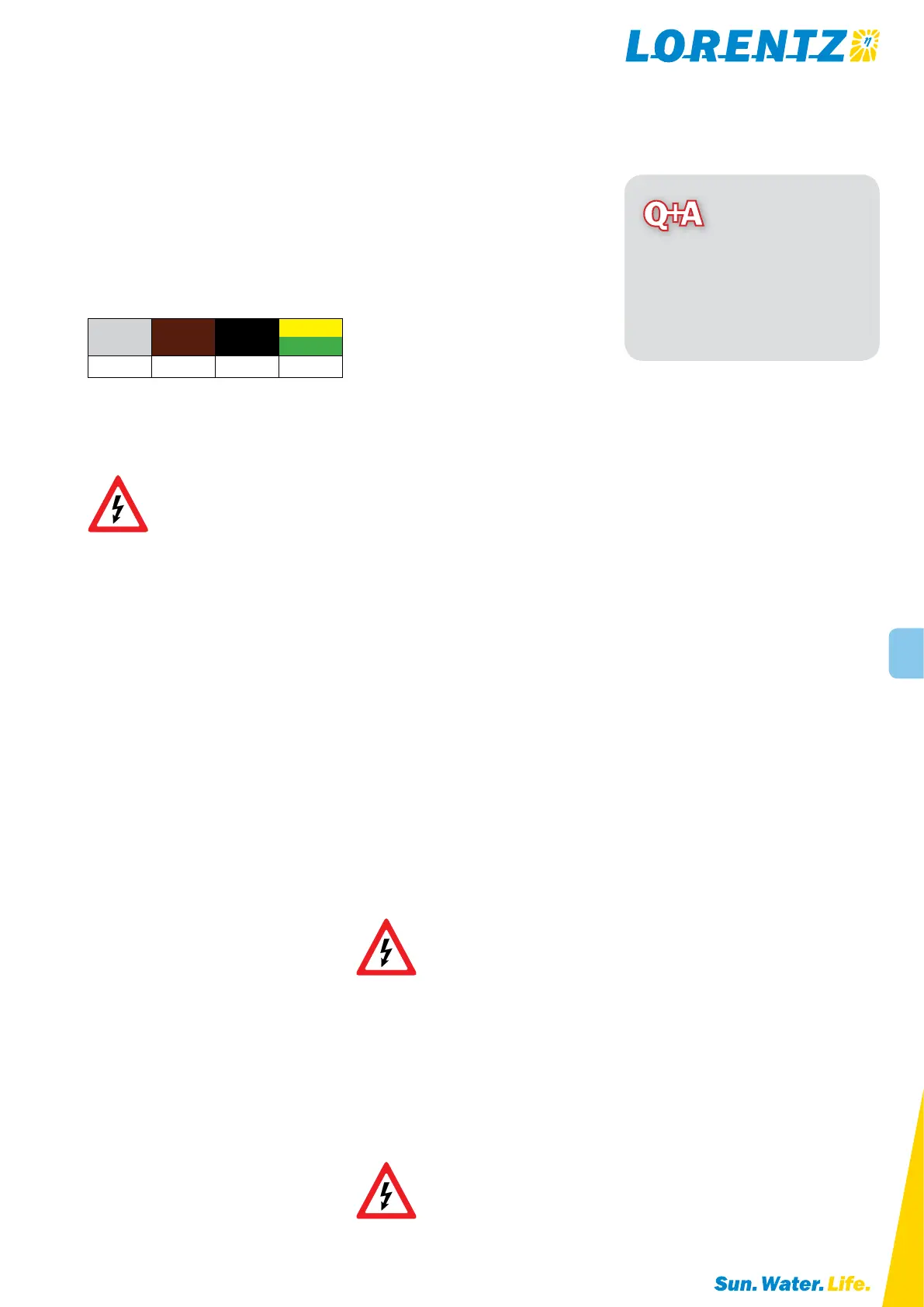

GREY BROWN BLACK

YELLOW-

GREEN

L1 L2 L3 Ground

The power wires on the pump may also be brown-black-

grey for Motors delivered before Q2 2005. Then use

brown as L1, black as L2 and grey as L3.

No disconnect switches must be

installed in power wires between

motor pump controller. Connecting

the motor wire to the switched-on

controller might irreparably damage it. Such

damages are excluded from the warranty.

4.9 Wiring Order for Correct Rotation

Testing the pump for direction Helical rotor pumps

will produce water flow only if they are rotating in

the right direction. If you place it in a water tank or a

bucket, you will observe flow if the rotation is correct.

(Submerge at least 75 % to observe full flow).

Alternative, dry test If you do not have a water ves-

sel to test the pump in, you can test it dry by watching

the pump shaft and running it for only a few seconds.

The metal label on the pump has an arrow to indicate

the proper direction of rotation. If the pump is new from

the factory, it is lubricated so it can run dry for about

90 seconds without risk. If the pump is not new, it can

be run dry safely for about 15 seconds. Either way, this

is more than enough time to observe the direction of

the shaft.

If you did not write down the color match (or the wind

blew your note away) connect the three power wires

to the controller in ANY random order. Apply power.

Observe the pump shaft rotation, then turn the power

off. If the direction is wrong, exchange ANY TWO of the

power wires at the controller. In any case, when you are

finished connecting the pump to the controller, test it to

assure the proper direction.

Did you install the pump in the well without

checking the wiring order or the direction?

OR – Is it running but not pumping?

HELICAL ROTOR pump (model number does NOT

contain “C”) Turn the pump on. Observe if air is rising

from the pipe. If it isn’t, reverse any two motor wires

and observe again. If you cannot observe air rise, chose

whichever direction is quieter (less vibration). There is

risk of dry-run damage if it runs too long in reverse. If

the pump is new from the factory, it is lubricated so it

can run dry for about 90 seconds without risk. If the

pump has been used, it

WARNING If the pump wires are in

the wrong order, the motor will run

in reverse and the pump will not

function. Damage may result.

Check the direction BEFORE installing the pump.

The proper direction is COUNTERCLOCKWISE

when viewed from above.

CENTRIFUGAL pump (model with C in the name)

In reverse, it will produce no flow (or very little). This

will NOT damage the pump. If the flow is not normal,

reverse any two motor wires.

WARNING When testing for

direction, do not run the pump dry

for more than 15 seconds.

QUESTION The motor shaft

is hard to turn by hand, and

moves in a bumpy manner. Is

this normal? – ANSWER YES. This is

caused by permanent magnets in the motor.

It is especially hard to turn when it is

connected to the controller, or if the pump

wires are connected together.

Loading...

Loading...