8

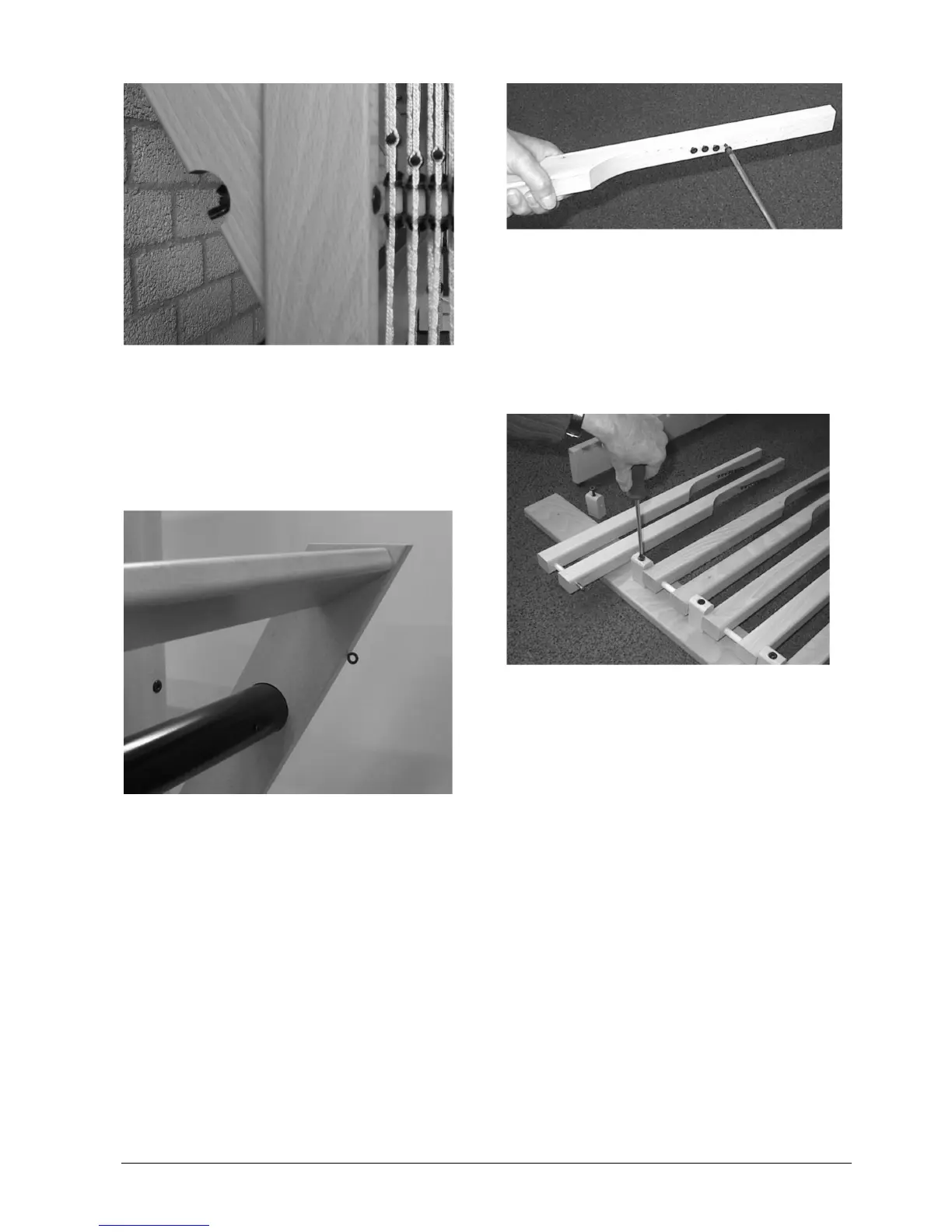

Take the two carriage bolts with washer and

wing nut and secure the back part as shown on

the picture.

When the loom is not in use, you can fold the

back part of the loom after removing the wing

nuts and washers again.

Screw the two screw eyes into the pilot holes at

the backside of the warp beam supports. If you

are used to leaving the lease sticks in the warp,

attach them to these eyelets.

Assembly of the foot rail and treadles

Open hardware bag 2:

− 80 screws 4 x 17 mm

− 4 screws 5 x 50 mm

− 6 screws 6 x 70 mm

− 5 axles Ø6 x 122 mm

− 5 nylon spacer bushings

− 6 axle support blocks

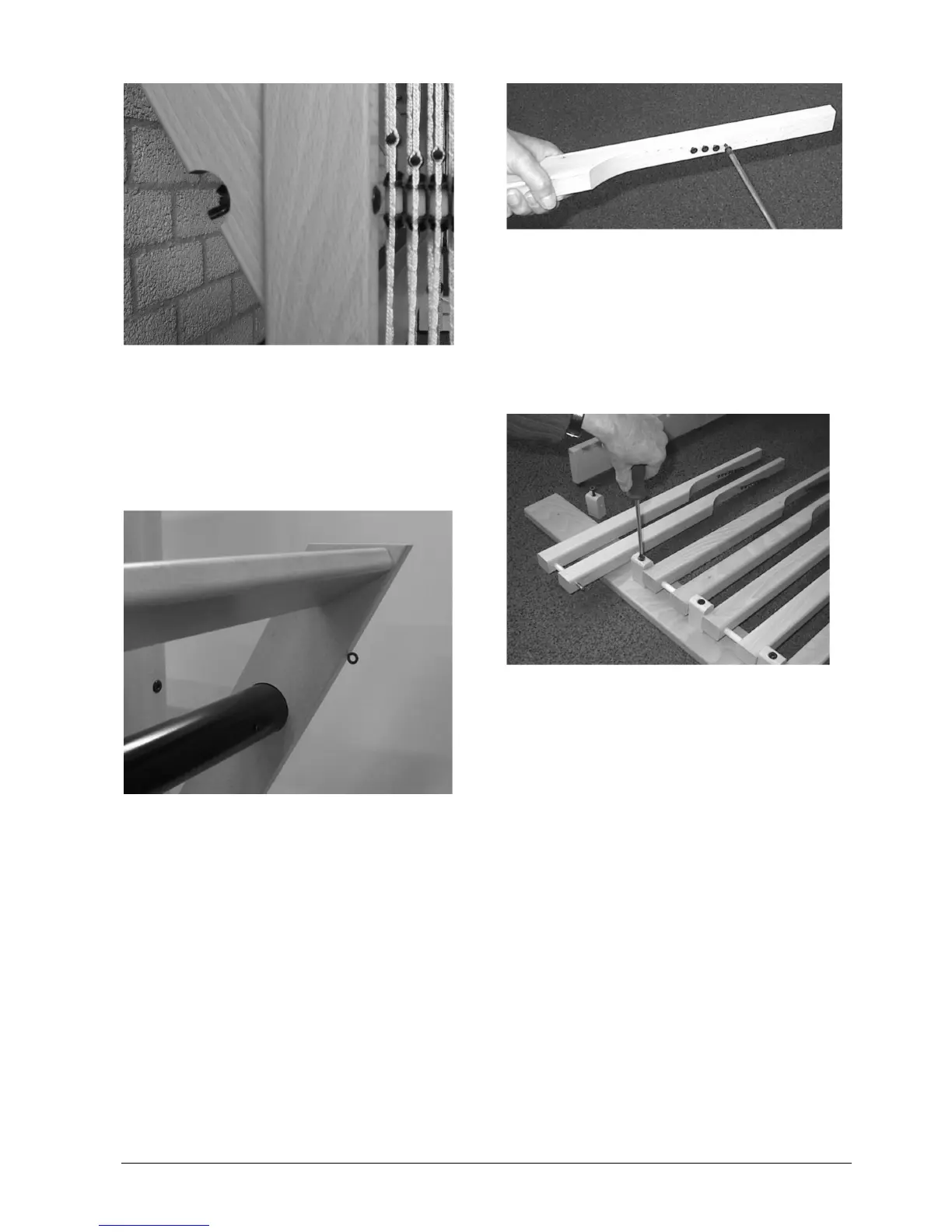

Screw the small screws into eight holes of each

treadle, so far that the screw heads protrude

approximately 5 mm (3/16”) from the wood. The

thread of the screws should just disappear into

the wood.

Use the eight holes closest to the end of the

treadle; the other four holes are to be used for

an extension to twelve shafts.

Place the foot rail upside down (pilot holes up)

on the floor in front of the loom.

Assemble the treadles onto the foot rail. The

screw heads on the treadles should point to the

right.

Slide two treadles with a nylon bushing in

between on each axle. Use the axle suspension

blocks and the big screws to assemble these

pairs of treadles to the foot rail. On each side,

one pilot hole on the foot rail should not be

used, unless you are assembling four more

treadles of an extension to twelve shafts.

Loading...

Loading...