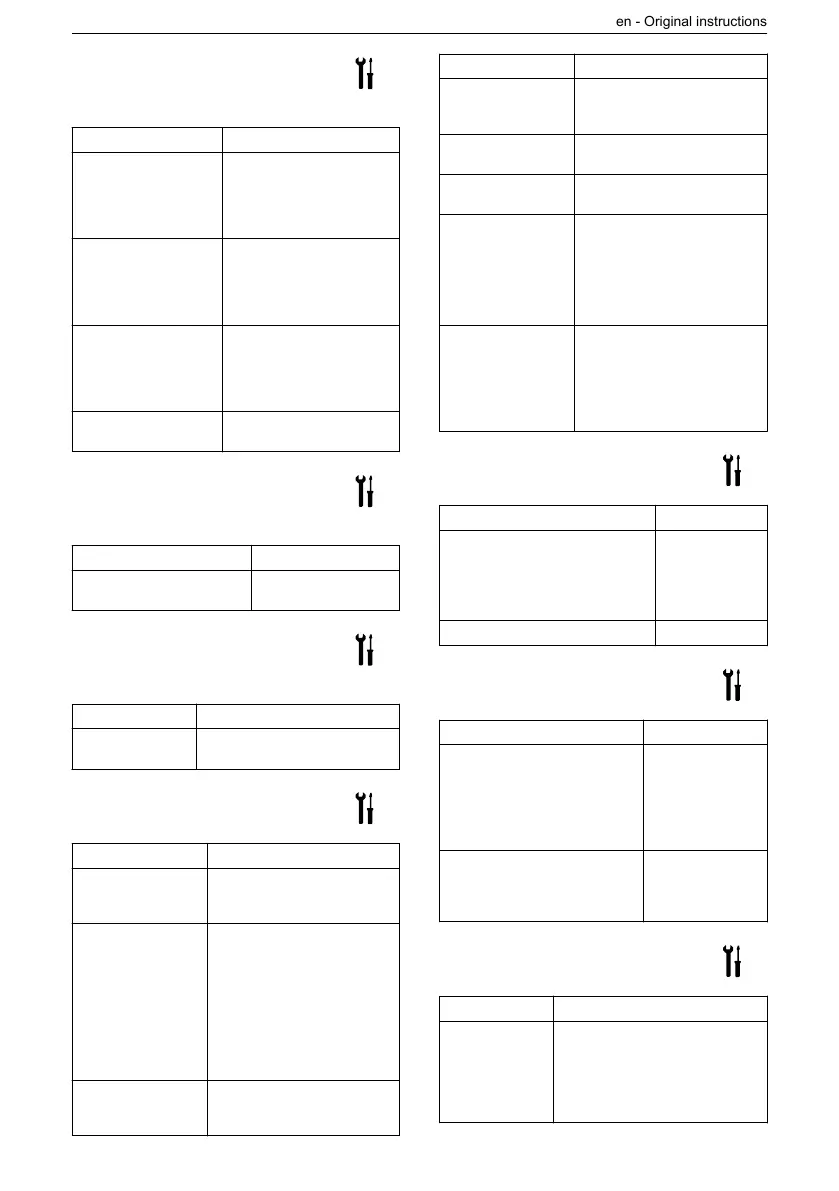

7.5 The electric pump starts, but

the thermal protector trips a varying

time after

Cause Remedy

There are foreign ob-

jects (solids or fibrous

substances) inside the

pump which have jam-

med the impeller.

Contact the local sales and

service representative.

The pumps delivery

rate is higher than the

limits specified on the

data plate.

Partially close the on-off

valve down stream until the

delivery rate is equal or

less than the limits speci-

fied on the data plate.

The pump is overload-

ed because it is pump-

ing liquid that is too

dense and viscous.

Check the actual power re-

quirements based on the

characteristics of the

pumped liquid and replace

the motor accordingly.

The motor bearings

are worn.

Contact the local sales and

service representative.

7.6 The electric pump starts, but

the system's general protection is

activated

Cause Remedy

A short circuit in the electri-

cal system.

Check the electrical

system.

7.7 The electric pump starts, but

the system's residual current device

(RCD) is activated

Cause

Remedy

There is an ground

(earth) leakage.

Check the insulation of the

electrical system components.

7.8 The pump runs but delivers too

little or no liquid

Cause

Remedy

There is air inside

the pump or the pip-

ing.

• Bleed the air

The pump is not cor-

rectly primed.

Stop the pump and repeat the

prime procedure.

If the problem continues:

• Check that the mechani-

cal seal is not leaking.

• Check the suction pipe for

perfect tightness.

• Replace any valves that

are leaking.

The throttling on the

delivery side is too

extensive.

Open the valve.

Cause Remedy

Valves are locked in

closed or partially

closed position.

Disassemble and clean the

valves.

The pump is clog-

ged.

Contact the local sales and

service representative.

The piping is clog-

ged.

Check and clean the pipes.

The rotation direc-

tion of the impeller is

wrong

(three-phase ver-

sion)

.

Change the position of two of

the phases on the terminal

board of the motor or in the

electric control panel.

The suction lift is too

high or the flow re-

sistance in the suc-

tion pipes is too

great.

Check the operating condi-

tions of the pump. If necessa-

ry, do the following:

• Decrease the suction lift

• Increase the diameter of

the suction pipe.

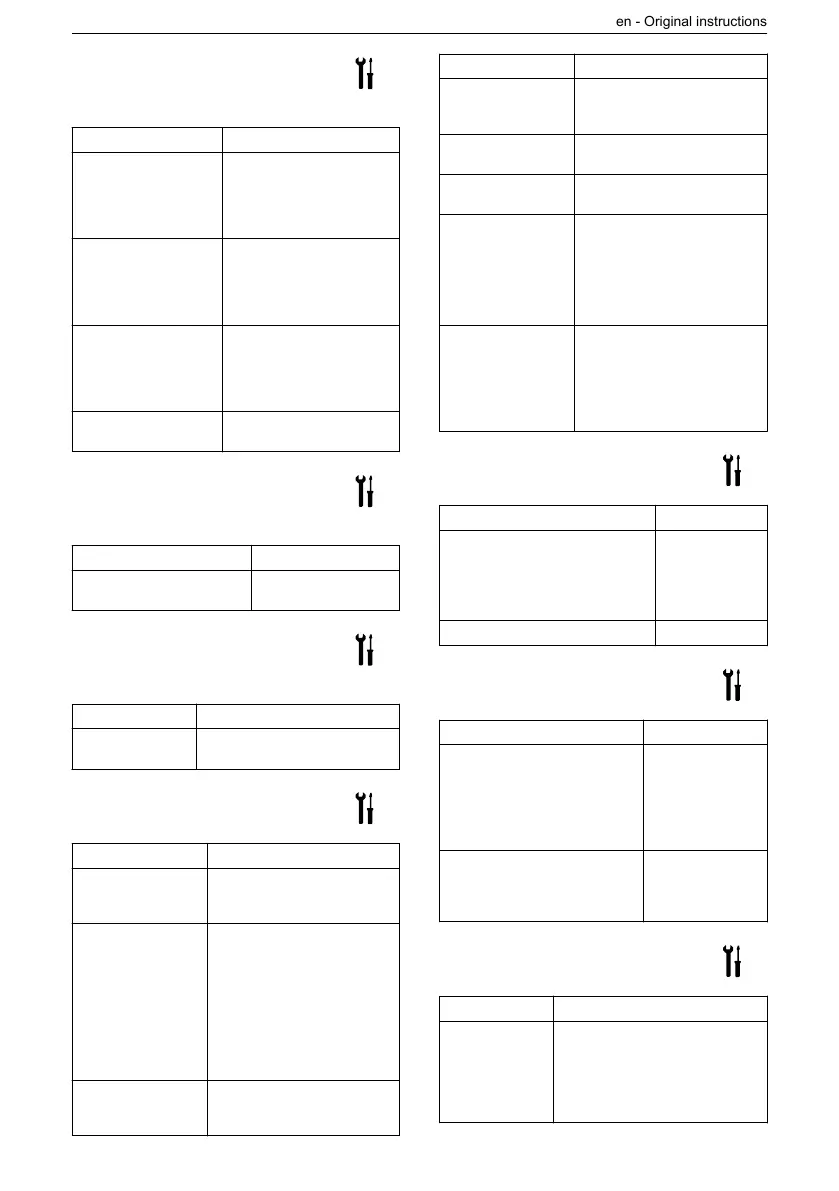

7.9 The electric pump stops, and

then rotates in the wrong direction

Cause Remedy

There is a leakage in one or both

of the following components:

• The suction pipe

• The foot valve or the check

valve

Repair or re-

place the faulty

component.

There is air in the suction pipe. Bleed the air.

7.10 The pump starts up too

frequently

Cause

Remedy

There is a leakage in one or

both of the following compo-

nents:

• The suction pipe

• The foot valve or the check

valve

Repair or replace

the faulty compo-

nent.

There is a ruptured membrane

or no air pre-charge in the pres-

sure tank.

See the relevant

instructions in the

pressure tank

manual.

7.11 The pump vibrates and

generates too much noise

Cause

Remedy

Pump cavitation Reduce the required flow rate by

partially closing the on-off valve

downstream from the pump. If

the problem persists check the

operating conditions of the pump

(for example height difference,

en - Original instructions

25

Loading...

Loading...