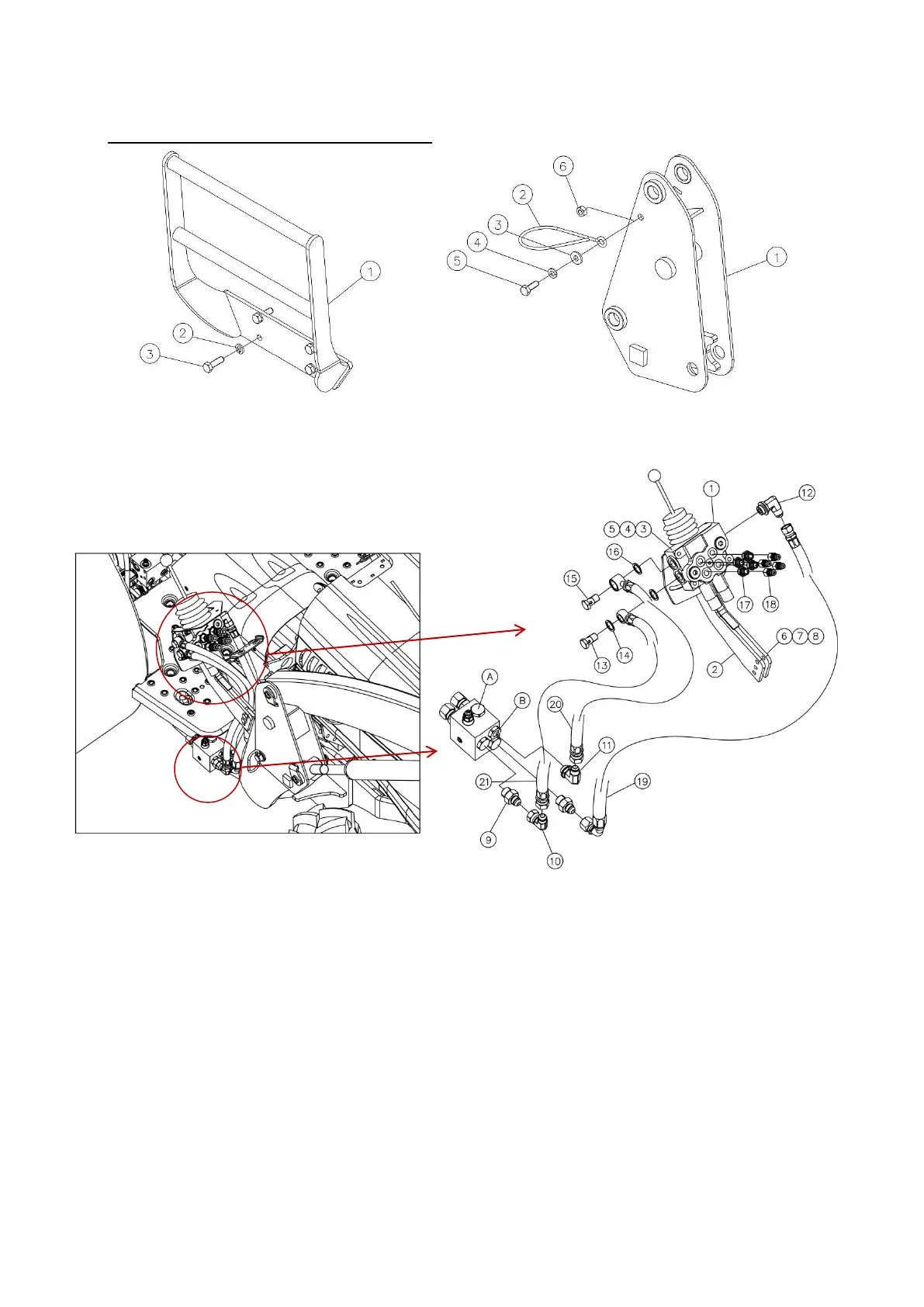

LOADER INSTALLATION

▶ Install Grille Guard

(1) BUMPER - 1EA

(2) SPRING WASHER M14 - 4EA

(3) BOLT M14x45Lx1.5P - 4EA

▶ Hose Guide

(1) COLUMN - 1EA

(2) HOLDER - 1EA

(3) PLAIN WASHER, M10 - 1EA

(4) SPRING WASHER, M10 - 1EA

(5) BLOT, M10x30L - 1EA

(6) NUT, M10 - 1EA

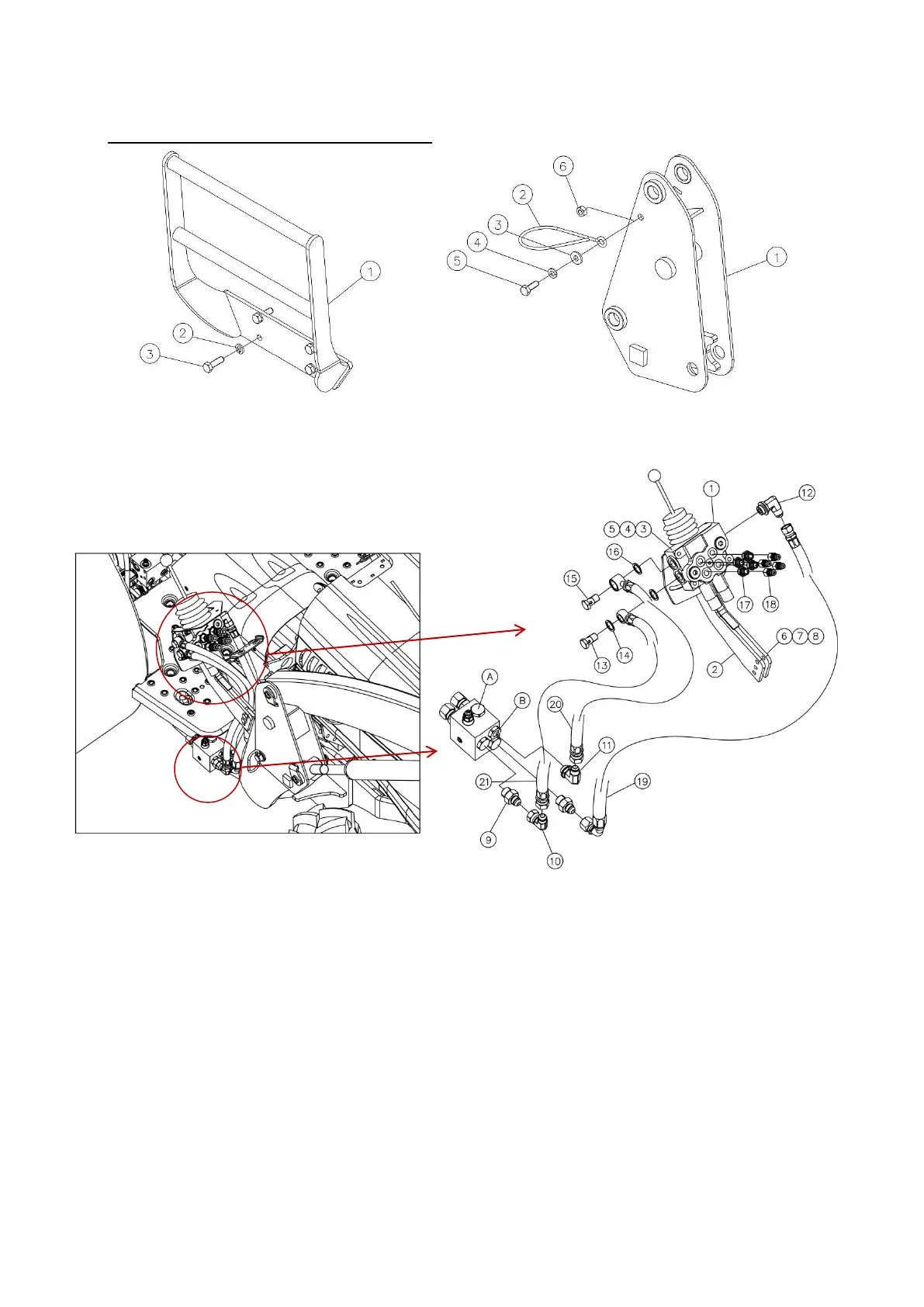

▶ Install Valve

(1) VALVE- 1EA

(4) SPRING WASHER, M8 - 3EA

(7) SPRING WASHER, M10 - 2EA

(10) ELBOW NIPPLE - 1EA

(13) BENJO BOLT – 1EA

(16) COPPER WASHER – 1EA

(19) HOSE, P LINE - 1EA

(2) BRACKET-C/V - 1EA

(5) NUT, M8 - 3EA

(8) NUT, M10 - 2EA

(11) ELBOW NIPPLE - 1EA

(14) COPPER WASHER – 2EA

(17) NIPPLE – 4EA

(20) HOSE, P/B LINE - 1EA

(3) BLOT, M8x70L - 3EA

(6) BLOT, M10x40L - 2EA

(9) NIPPLE - 2EA

(12) ELBOW NIPPLE - 1EA

(15) HOUSING – 1EA

(18) Q-COUPLING - 4EA

(21) HOSE, T LINE - 1EA

※ Remove the plug from “B” port of Hydraulic block, and then install it onto “A” port.

Verify that all mounting kit hardware has been torqued as specified before installing loader.

▶ Identify hardware size and grade.

▶ Refer to Torque Chart, page 24 and find correct torque for your hardware size and grade.

▶ Torque hardware to this specification unless otherwise specified.

▶ IMPORTANT NOTE: To keep mounting kit hardware from loosening during loader operation,

hardware must be torque to specifications.

Loading...

Loading...