CDA3000 Operation Manual

3-5

3 Electrical installation

1

2

3

4

5

A

DE

EN

FR

IT

ES

FR

Attention: If the inverter is operated as a controller with encoder (FOR

motor control method), motor phases U,V and W must

never be reversed! If the motor phases are reversed the

inverter has no control over the motor. The motor may buck or

accelerate in an uncontrolled manner (“race”).

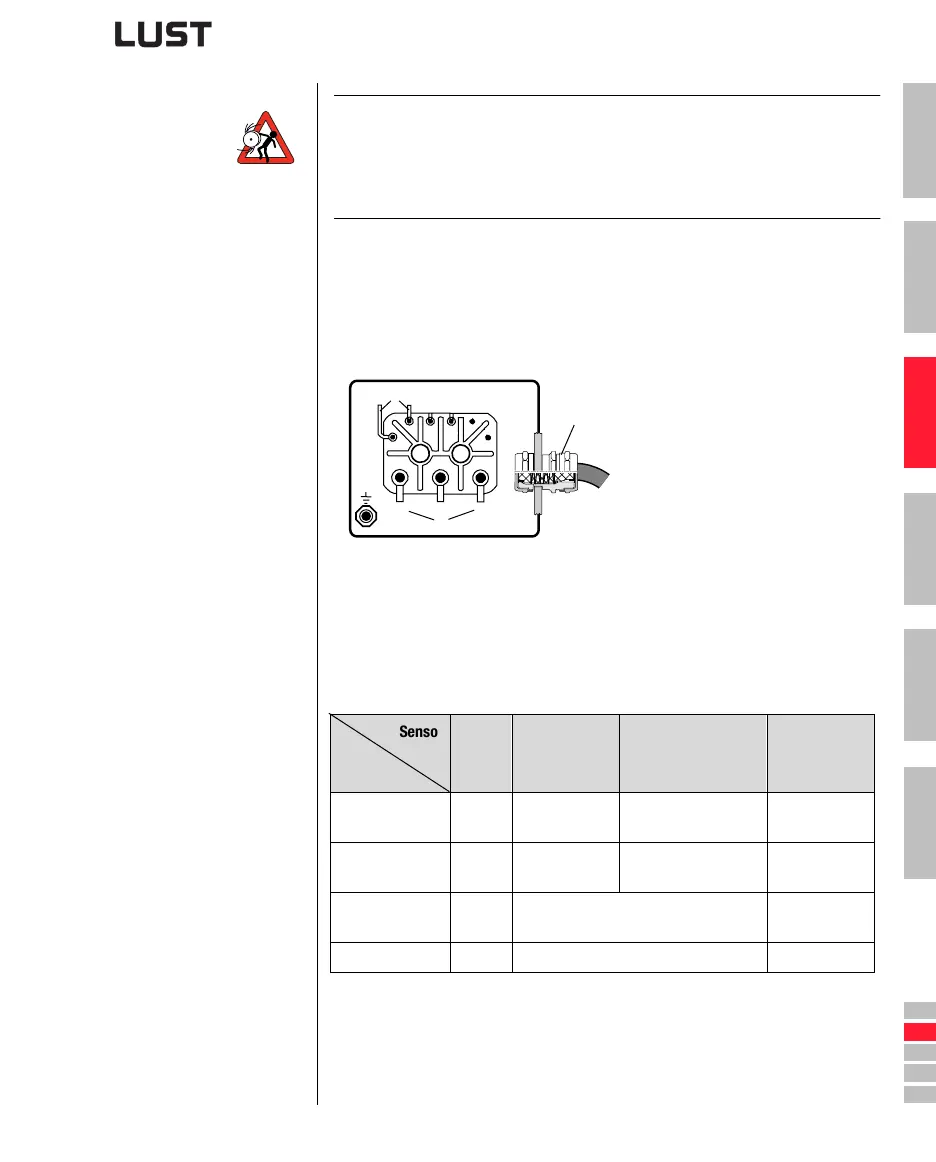

Terminal box

For proper EMC installation the motor terminal box must be HF-tight

(metal or metallized plastic). For the cable entry, packing glands with

large-area shield contact should be used.

Motor temperature monitoring

For thermal monitoring of the motor coil, a thermistor (PTC) may be con-

nected to terminals X3/ϑ− and ϑ+. The type used must be set during

commissioning in parameter 330-MOPTC (factory default setting is "off").

(1) Thermistor (PTC)

(2)

Packing gland with shield

contact

(3) Motor phases

(4) Grounding lead connection

Figure 3.4 Motor terminal box

1

2

U

VW

U

VW

(1)

(2)

(3)

(4)

Sensor

Tech. data

No PTC

used

Standard

PTC

Linear

voltage evaluation

TSS -

Thermostatic

circuit-breaker

Usable type –

PTC to

DIN44082

KTY84, yellow Klixon

Parameter

330-MOPTC =

OFF DIN KTY TSS

Measured voltage

UMAX

– 12 V –

Measuring range – 100

Ω

to 15 k

Ω

–

Table 3.1 Motor temperature monitoring specification

Loading...

Loading...