31

MAC 6000 Hydronic Heater

Trailer Axle Manual

2106 East Indiana Ave., Bismarck, ND 58504 U.S.A. • www.macheaters.com • +1-800-272-4604

8

Rev: 07.25.2013

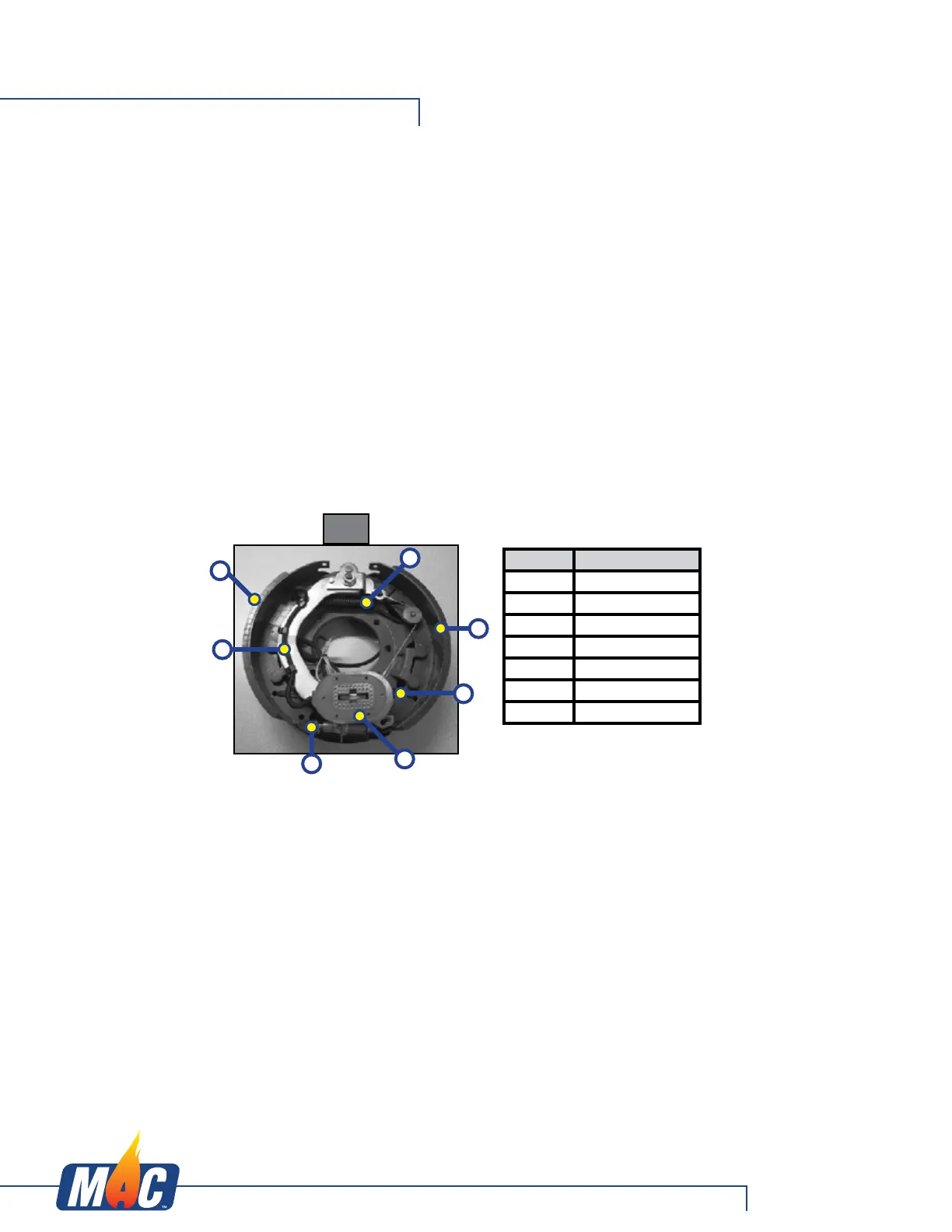

ELECTRIC BRAKES

The basic structure of the Electric Brakes on your trailer will resemble the brakes on

your car or tow vehicle, with one major difference; your trailer implements an Electric

Actuation system and your tow vehicle utilizes a hydraulic system. The Electric Braking

System operates in the following order of steps; refer to the Electric Braking System

Diagram and the brake diagram (Fig. 5) to follow along:

1. Electric current is supplied to the trailer’s braking system when the tow vehicle’s

brakes are applied.

2. From the tow vehicle’s battery, the electricity flows to the brake’s electromagnet.

3. When energized the magnets are attracted to the rotating surface of the drums.

4. This moves the actuating levers in the direction the drums are turning.

5. The actuating cam at the end of the shoe forces the primary shoe out to the

drum surface.

6. The force of the primary shoe actuates the secondary shoe to contact the drum.

7. The force applied to the brake drum can be increased by elevating the current

flow to the magnet.

Fig. 5

A

B

C

D

E

F

G

Callout Component

A Primary Shoe

B Actuating Lever

C Adjuster

D Magnet

E Adjusting Spring

F Secondary Shoe

G Retracting Spring

HOW TO USE LIPPERT ELECTRIC BRAKES PROPERLY

The Lippert Components, Inc. Electric Braking System is synchronized with the tow

vehicle brakes. Never attempt to stop the combined load of the tow vehicle and

the trailer by using either the tow vehicle brakes or the trailer brakes only. They are

designed to work together.

Small manual adjustments may occasionally be necessary to accommodate changing

loads and driving conditions. Synchronization of tow vehicle to trailer braking can only

be accomplished by road testing. Locking up, excessive grab, or delayed application is

quite often due to the lack of synchronization between the tow vehicle and the trailer

being towed. High voltage (2V+), Low voltage (2V-) or improperly adjusted brakes are

the most common causes of these problems and can be easily remedied.

Prior to any adjustments, your trailer brakes should be burnished-in by applying the

brakes 20-30 times with a 20 m.p.h. decrease in speed, e.g. 40 m.p.h. to 20 m.p.h. Allow

ample time for brakes to cool between application. This allows the brake shoes and

magnets to begin seating to the brake drum.

Loading...

Loading...