32

MAC 6000 Hydronic Heater

Trailer Axle Manual

2106 East Indiana Ave., Bismarck, ND 58504 U.S.A. • www.macheaters.com • +1-800-272-4604

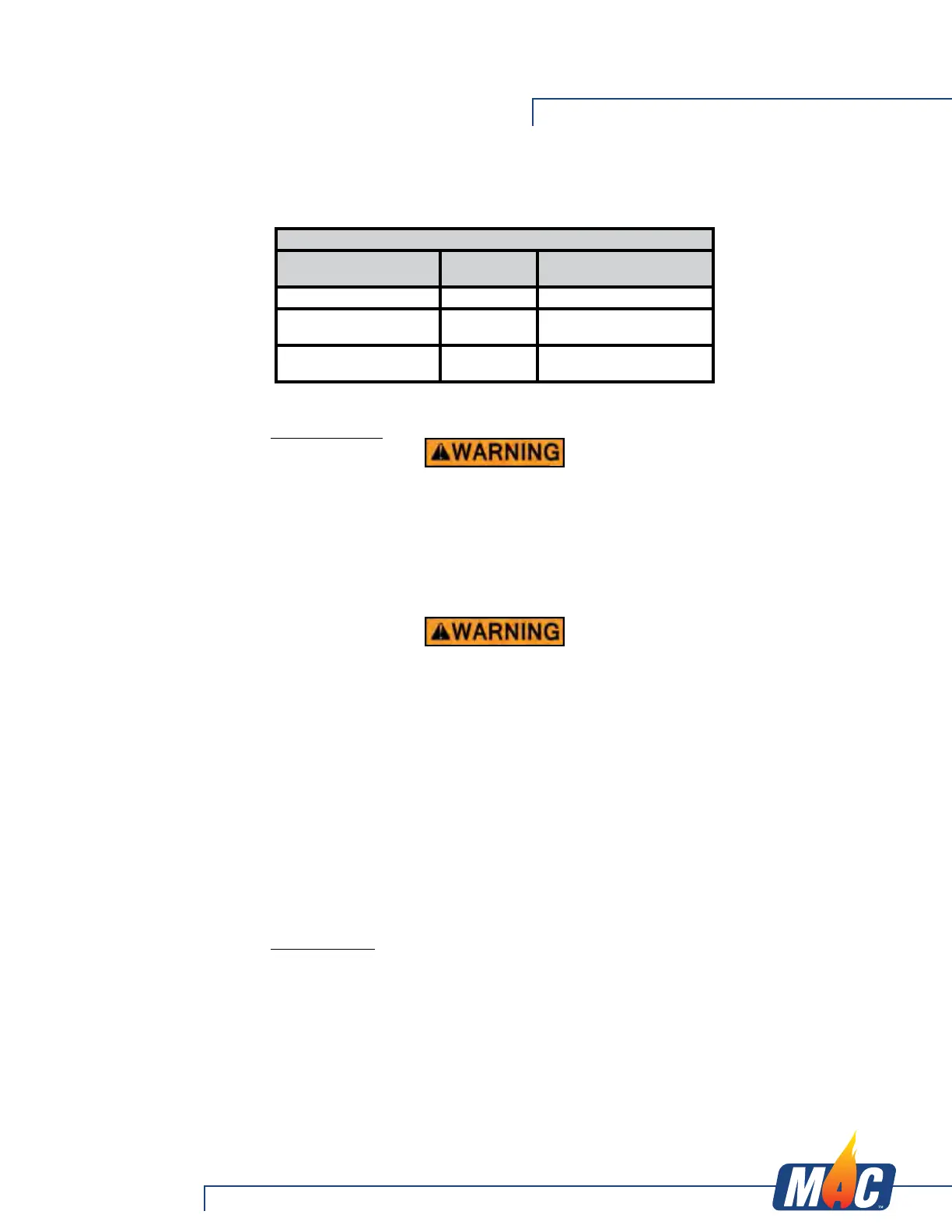

Trailer Wire Gauge Chart

Wire Gauge and Type

Number of

Axles

Length of Run

16 Ga Stranded Copper 1 N/A

14 Ga Stranded Copper 2

Under 30ft. (9.1m) from

hitch to center of axles

12 Ga Stranded Copper 2 or 3

Over 30ft. (9.1m) from

hitch to center of axles

GENERAL MAINTENANCE - ELECTRIC BRAKES

BRAKE ADJUSTMENT

Prior to testing or adjusting brakes, be sure area is clear of any persons and

vehicles. Failure to perform test in a clear area may result in serious injury or

death.

Lippert Components, Inc. Electric Brakes are automatic adjust only. If manual adjusting

is needed, the following 6-step procedure can be utilized. The brakes should be

adjusted in the following manner:

1. Jack up trailer and secure on adequate capacity jack stands. Follow trailer

manufacturer’s recommendations for lifting and supporting the unit. Make sure

the wheel and drum rotates freely.

Lift unit by frame and never the axle or suspension. Do not go under unit unless

it is properly supported by jack stands. Unsupported units can fall causing

serious injury or death.

2. Remove the adjusting hole cover from the adjusting slot on the bottom of the

brake backing plate.

3. With a screwdriver or standard adjusting tool, rotate the starwheel of the

adjuster assembly to expand the brake shoes. Adjust the brake shoes out until

the pressure of the linings against the drum makes the wheel very difficult to

turn.

4. Then rotate the starwheel in the opposite direction until the wheel turns freely

with a slight lining drag.

NOTE: A second screwdriver will be needed to push the auto adjusting lever away

from the adjuster starwheel so that the starwheel can be rotated backwards.

5. Replace the adjusting hole cover and lower the wheel to the ground.

6. Repeat the above procedure on all brakes. For best results, the brakes should all

be set at the same clearance.

LUBRICATE BRAKES

Prior to reassembling the brake drum assembly, remember to apply a light film of

white grease or an anti-seize compound on the brake anchor pin, the actuating arm

bushing and pin, and the areas on the backing plate that are in contact with the brake

shoes and magnet lever arm. In addition apply a light film of grease on the actuating

block mounted on the actuating arm.

Electric Brake Maintenance

Loading...

Loading...