Page 8 of 14 507860-01Issue 1927

Air Filter

All indoor return air must be ltered. A washable lter is

furnished with the unit, located in the return air compartment.

If the optional front return opening is used and a duct is

installed, provisions must be made to accommodate lter

servicing. If a lter is installed at a separate central return

location, then the factory furnished lter must be removed

from the unit.

The lter should be cleaned at least three times during

each of the heating and cooling seasons, or more

frequently if unusual conditions are encountered. To clean

the washable lter, shake lter to remove excess dirt and/

or use a vacuum cleaner. Wash lter in soap or detergent

water and replace after lter is dry. It is not necessary to oil

the lter after washing.

The washable lter may be replaced with a disposable

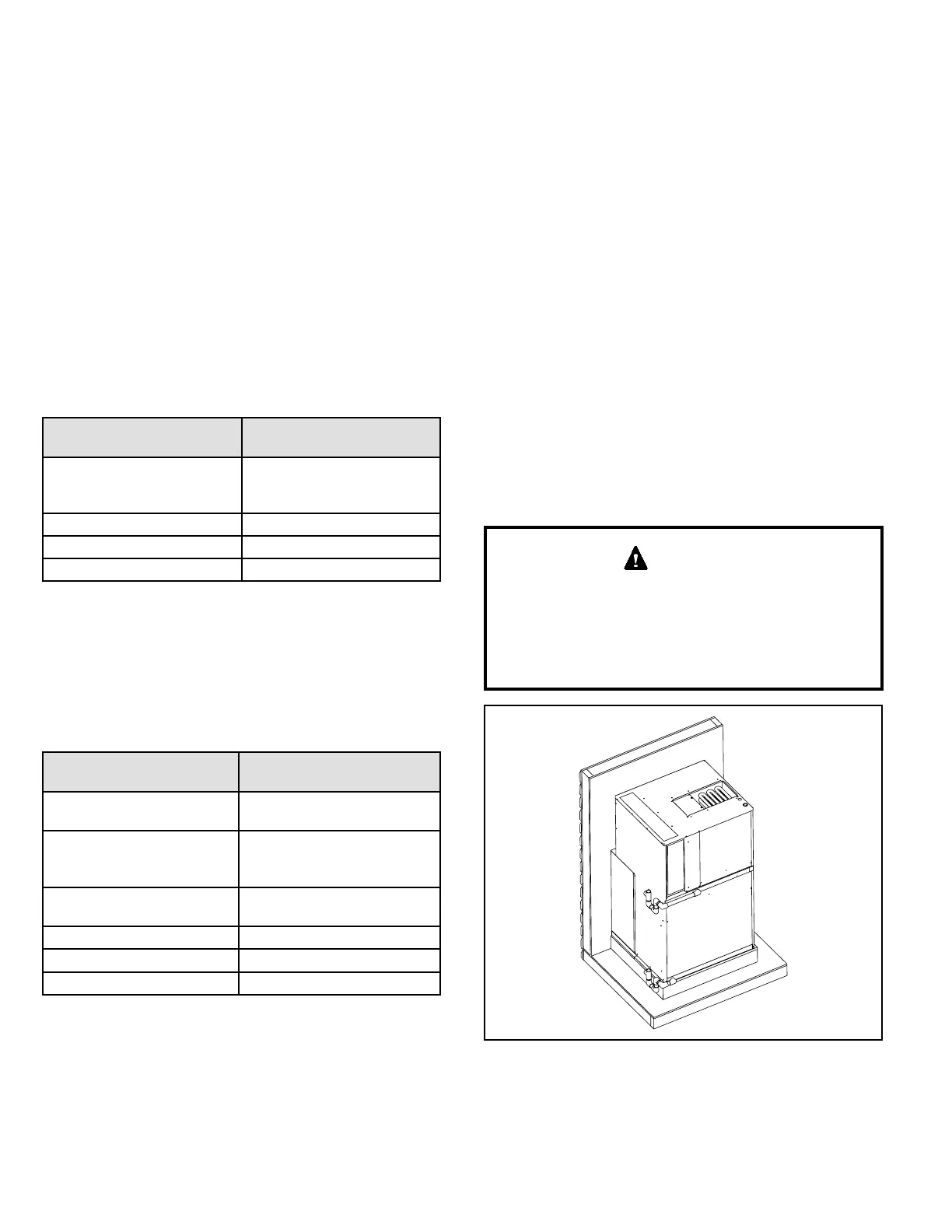

lter. Table 4 lists lter sizes that t the unit.

Model Number

Filter Size

(in.)

*MCE4-11-09*

*MCE4-11-12*

*MCE4-11-18*

18 x 20 x 1

*MCE4-11-24* 20 x 22 x 1

*MCE4-11-30* 22 x 24 x 1

*MCE4-11-36* 22 x 28 x 1

Table 4. Filter Sizes

If an installation is made in which it is more desirable to

mount the lter exterior to the unit, in the return duct work

or elsewhere, the washable lter can be used or replaced

with a disposable lter. If a disposable lter is used, use the

information provided in Table 5 when sizing the disposable

lter.

Model Number

Filter Area

(in

2

)

*MCE4-11-09*

*MCE4-11-12*

250

0MCE4-11-18*

3MCE4-11-18*

5MCE4-11-18*

310

7MCE4-11-18*

10MCE4-11-18*

380

*MCE4-11-24* 420

*MCE4-11-30* 480

*MCE4-11-36* 575

Table 5. Minimum Required Surface Area for

Disposable Filters

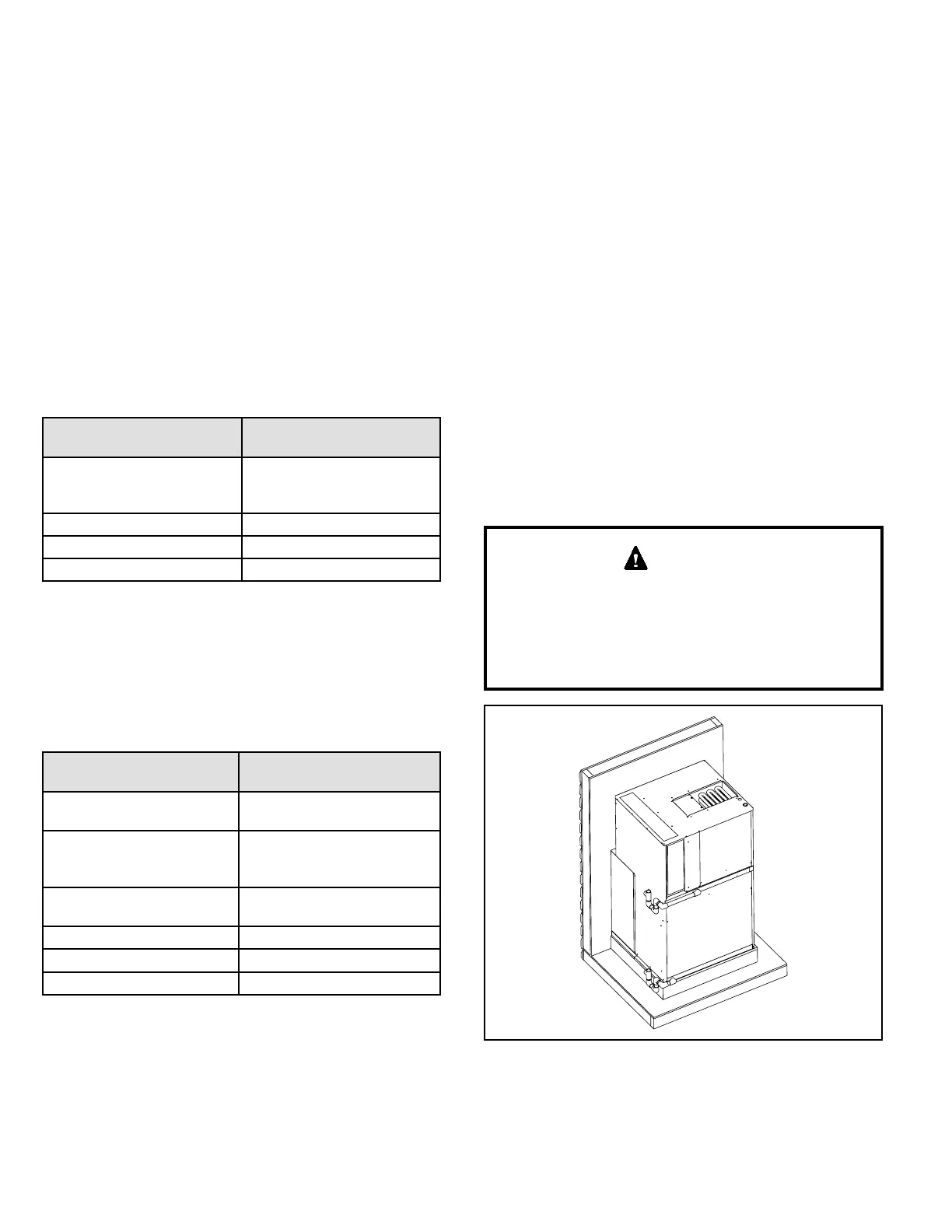

Condensate Drain

Provisions must be made to properly drain the indoor and

outdoor drain pans of this appliance.

Indoor drain and outdoor drain connection: 3/4” NPT to

3/4” PVC tting (schedule 40 minimum). Both drains must

be trapped as shown in Figure 6. The drain line should

pitch gradually downward at least 1” per 10’ of horizontal

run to an open drain.

If local codes require the use of metal condensate lines,

do not thread metal ttings into the unit drain pans. Thread

a PVC tting into the unit drain pans and make the eld

connection to the PVC tting.

NOTE: MCE units are designed with a redundant drain

system to handle condensate without the need for a

secondary or emergency drain pan. Should the indoor

coil condensate drain system fail, all water is contained

within the unit and the ow is directed into the unit base

pan. From there it will drain into the condensate riser.

If for some reason the water cannot drain into the main

condensate riser, all water is contained in the unit, and the

design will allow drainage out through the wall sleeve and

louver assembly to the outside of the building.

Use thread sealant on the threaded ttings. Install

threaded ttings by hand only. Do not over torque the

ttings.

Do not thread metal condensate ttings to unit drain

pans.

CAUTION

Figure 6. Condensate Drain Installation

Loading...

Loading...