C-66

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

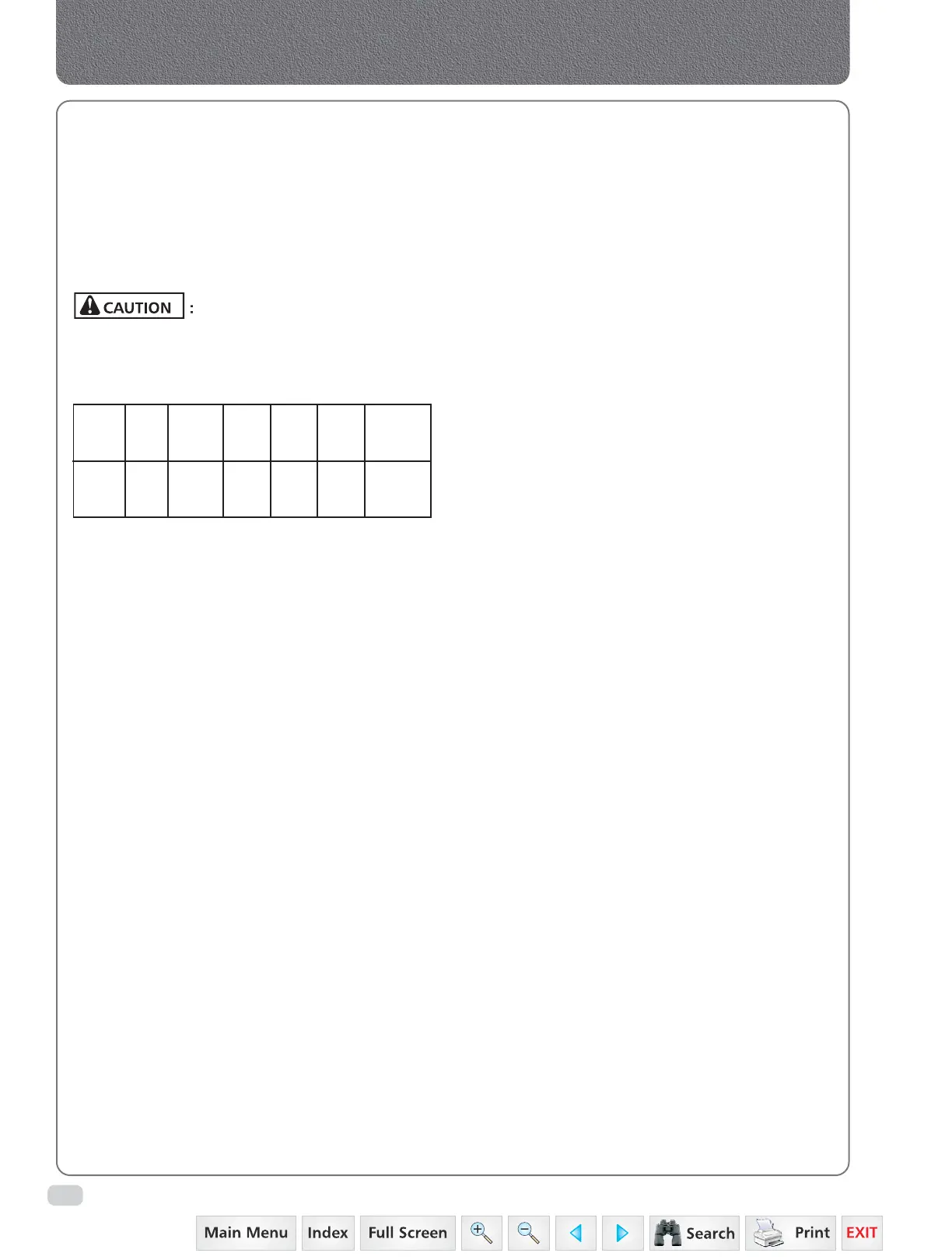

Thread

size

NPTF

Threads

per

inch

Pitch D

Ø

G

Length

Assembly

TFFT

3/4” 14 0.071

1.81

1.05

26.56

0.34

8.6

2.0–3.0inch

mm

inch

mm

Table A

Crankcase, Crankshaft, Main Bearings & Flywheel

2. Apply sealant (Teflon tape) / lubricant to male

NPT threads (Pre-applied dry sealant are

preferred over other sealants). With any

sealant, the first one to two threads should

be let uncovered to avoid system

contamination. If PTFE tape is used it should

be wrapped 1.½ to 2 turns in clockwise

direction when viewed front the pipe thread

end.

More than two turns of tape

may cause distortion or cracking of the port.

3. Screw the connector into the port to the finger

tight position.

4. Wrench tighten the connector to the

appropriate T.F.F.T. Values shown in the table

A, making sure that the tube end of a shaped

connector is aligned to receive the incoming

tube or hose assembly. Never back off (loosen)

pipe threaded connectors to achieve

alignment.

5. If leakage persists after following the above

steps, check for damaged threads and total

number of threads engaged.

If threads on the fitting are badly nicked or

galled, replace the fitting. If port threads are

damaged, re-tap, if possible, or replace the

component. If the port is cracked,

replace the component.

CHECKING COMPRESSION

Use compression gauge to check compression in

all cylinders of the engine individually. (It is advisable

to check cylinder compression before overhauling.

Comparison of these figures will disclose errors or

show improvements.)

To check the cylinder compression, screw in a plug

port adapter in place of the injector of the respective

cylinder and connect with compression. Draw up

both connections tight.

Close the vent valve of the compression gauge and

crank the engine briefly by means of the starting

motor. Only a few cycles of the engine are required

to obtain a satisfactory reading. After taking the

reading retard the pointer on the dial all the way

by opening the vent valve. Close the valve again

and repeat the check to make sure that the reading

is correct.

Check compression in all cylinders of the engine

as described above. The compression shown on the

gauge is 16½ atu. (235 lbs. per sq. in.) each

graduation mark being 2 atu. (28½ lbs. per sq. in.).

With the engine warmed up, normal compression

in the cylinders is 16 to 18 atu. (228 to 256 lbs.

sq. in.) at the speed of 100 r.p.m. (starting motor

speed).

Compression pressure should be nearly equal in all four

cylinders of the engine. When a reading is taken that

deviates considerably from the above specifications,

as for example 14 atu. (200 lbs. p. sq. in.) and below,

the cause must be determined and the trouble

remedied.

Check for leaking valves, faulty piston rings and

worn pistons or cylinder sleeves.

Loading...

Loading...