D-9

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

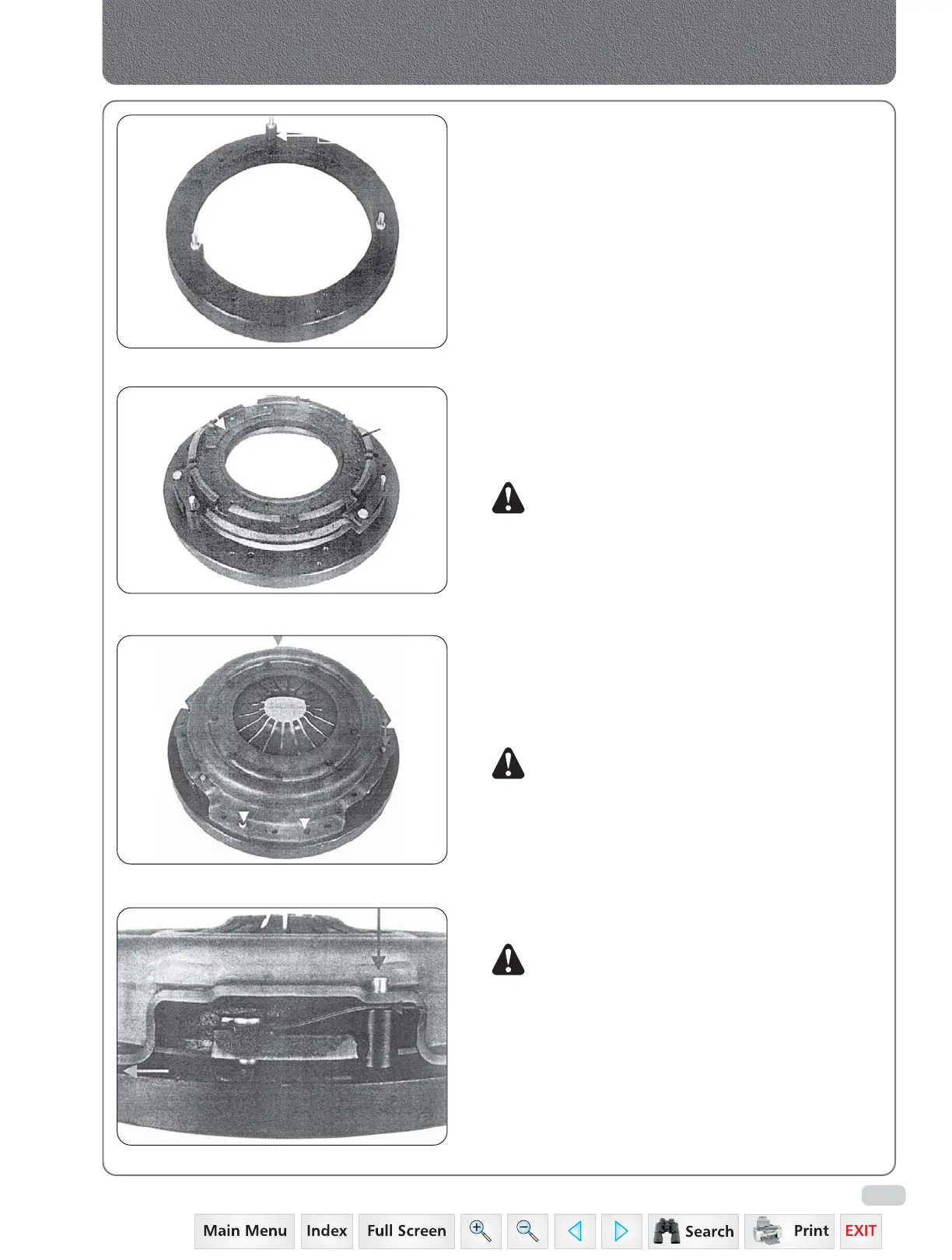

Fig. 12

Fig. 11

8. Take 3 bushes and fix it on the outer ring fixture.

9. Keep the pressure plate fixture accordingly as

shown in fig.11.

10. Take pressure plate sub. assy. and keep it over the

fixture as shown fig.12.

11. Ensure that whether the drive straps are properly

seated over rivet.

12. Place the cover & diaphragm sub-assy. over the

pressure plate sub-assy. Then tighten the cover

sub-assy. against the outer ring.

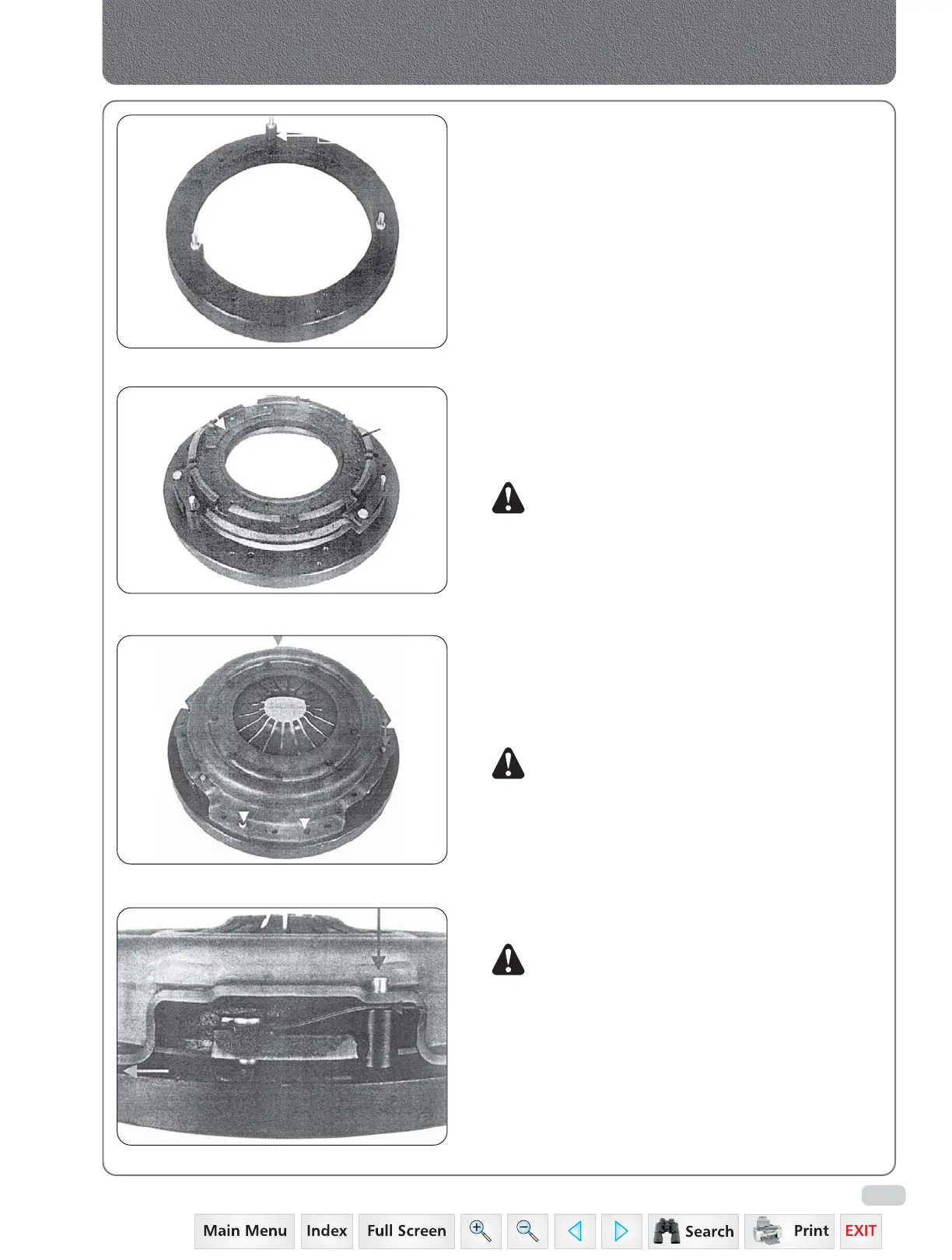

13. Cover the mounting holes locations are marked

thus (fig.13).

14. Use press to rivet the cover.

Finally loosen the mounting screws and take out

clutch assy.

NOTE:

1. There should not be any gap between cover

to fixture during assembly.

2. No gap between drive strap and rivet head

after riveting.

3. Form riveted head dia 10-11 min.

8. INSTALLATION

a. THE SINGLE PLATE CLUTCH

1. A pilot tool which will slide through the bore of

the driven member and locate in the pilot bearing

of the flywheel will aid installation of the clutch.

NOTE: The end of a transmission shaft will serve for

the single clutch, or a special tool is available.

See special tool list.

2. Lift the clutch assembly with driven member, and

position it on the flywheel dowel with the pilot

tool located in the pilot bearing in the flywheel.

3. Align the punch marks on the cover and flywheel

then insert and tighten the securing cap screws

and lock washers.

NOTE: The clutch securing capscrews should be

tighten a turn at a time by diagonal selection

til secured to avoid distortion of the cover

flange.

4. Withdraw the pilot tool.

5. Installation is now the reversal of the “REMOVAL”

procedure.

Fig. 14

Fig. 13

Clutch

Loading...

Loading...