G-24

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

Electrical System

Alternator

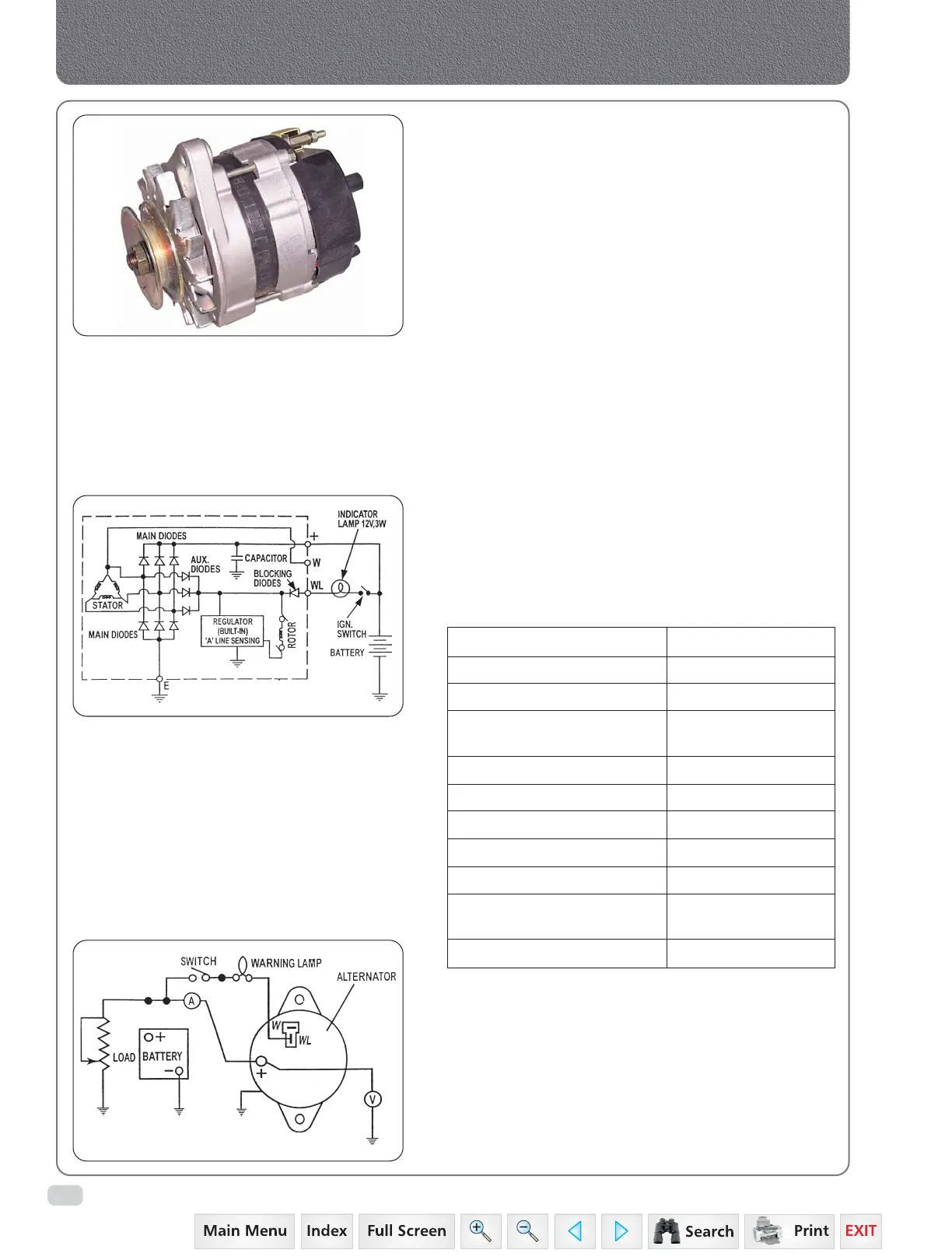

Wiring Diagram for Alternator

C. ALTERNATOR

1. GENERAL DESCRIPTION

This Alternator is built-in with Electronic Regulator is

designed and matched to form part of an Battery Charging

& Electrical Power System for Tractor applications. This

alternator is suitable for negative earth systems.

2. SALIENT FEATURES

• Delta connected 3-phase output winding wound

on a laminated stator.

• 12-pole wound field rotor, carried on ball-race

bearings in aluminium end brackets and belt

driven from engine.

• Self-excited field (via three field diodes) at normal

running speeds.

• Built-in rectifier provides rectification of generated

A.C.

• Voltage control is provided via a built-in electronic

regulator.

• An RFI suppression capacitor is provided across

the positive and negative terminals.

• A phase terminal can be made available if

required.

3. SPECIFICATIONS FOR ALTERNATOR

1. Type 3GA15

2. Rating Continuous

3. Normal Output 12 V

4. Weight 7 Kg Approx.

(Incl. Pump & Pulley)

5. Rated Max. Output Speed 6000 R.p.m.

6. Max. Permissible Speed 11,500 R.P.M.

7. Polarity Negative Earth

8. Regulator System Built-in Regulator

9. Reg. Set Voltage 14.1 – 14.6 V

10. Direction of Rotation Clockwise (Viewed

From Pulley Side)

11. Operating Temperature –30ºC To 100ºC

4. CHECKING AFTER RE-ASSEMBLY ALTERNATOR

1. Clamp the Alternator in a test rig.

2. Connect as shown in figure.

3. Observe correct polarity of battery.

4. Connect oil inlet, outlet and vacuum connection.

5. Close the switch, warning lamp should glow.

6. The oil pump and the main drive should be

switched ‘ON’ simultaneously.

Loading...

Loading...