C-34

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

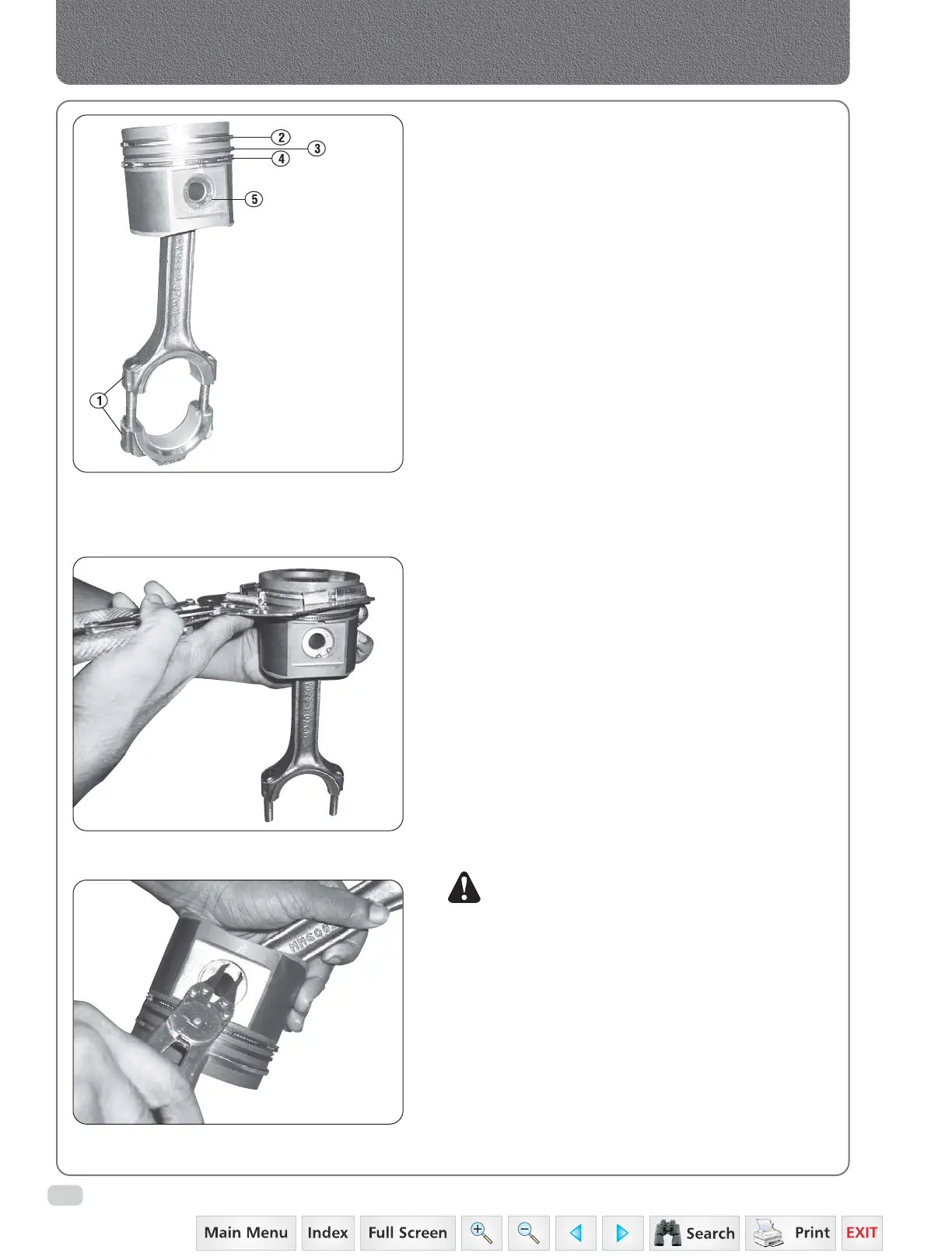

Fig. 3

Connecting Rod & Piston Assembly

Fig. 4

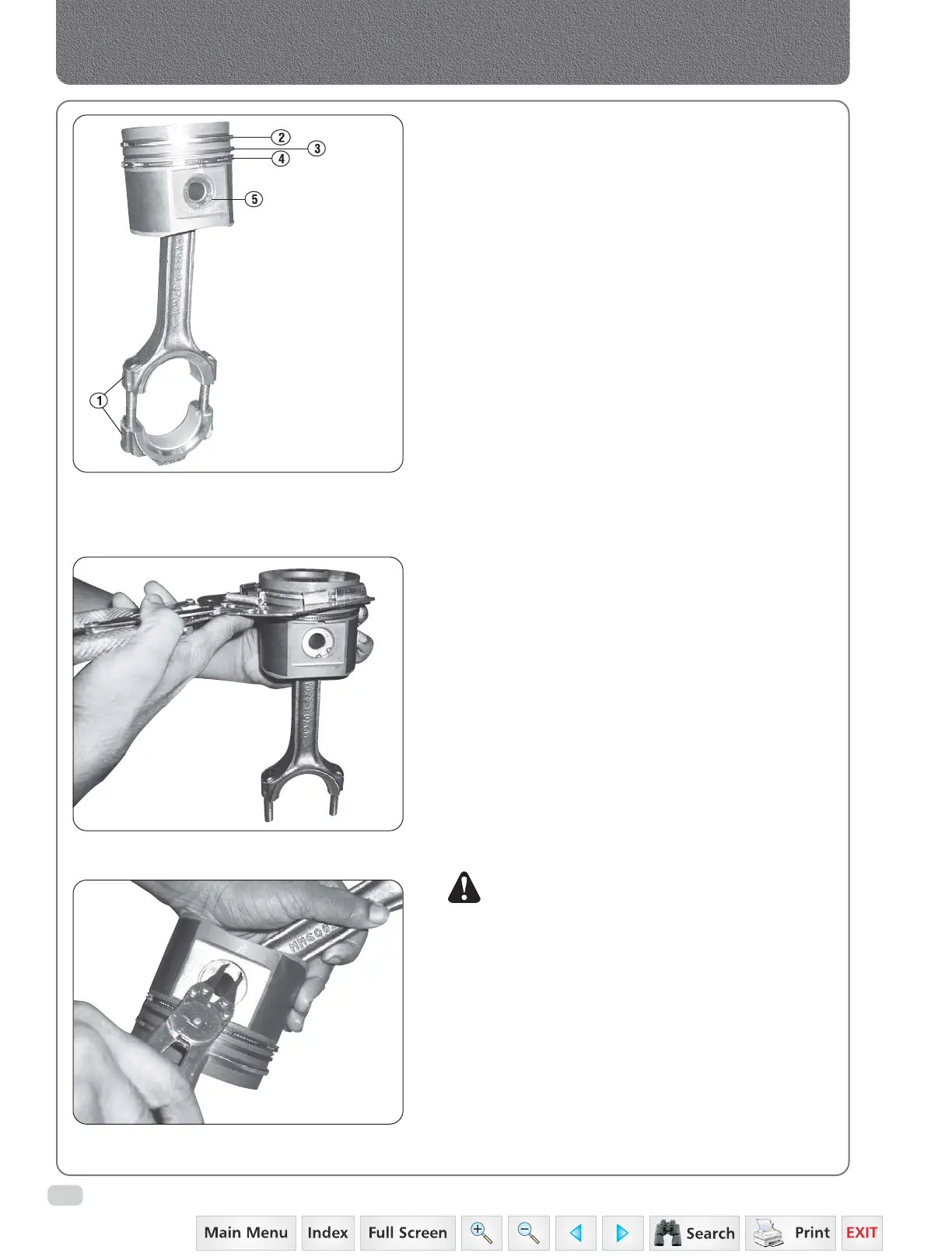

Removing or installing piston pin circlips

Removing or installing piston rings with ring expander

1. Cylinder number

2. Top compression

ring

3. Zud Compression

ring

4. Oil control rings

5. Piston pin snap

ring

c) Check the connecting rods for alignment (Fig.6).

The bores must be square and parallel with each

other in all planes within +0.12 (+0.005 inch)

(L-6) measured 127 mm (5 inches) each side of

the centre line (A-6), if necessary realign by

straightening the connecting rod or replace them.

d) Check the threads in the connecting rod big end

for wear and damage.

e) Check the wear and condition of the connecting

rod bushings. If replacement is necessary proceed

as follows :

1. Press out the old bushing (10-2).

2. Align the oil hole in the new bushing with

the oil hole in the connecting rod and, using

a pilot dolly, press the bushing into the rod.

3. Ream the bushing to the dimension given

in specifications and check the fit of the

piston pin.

f) Check the piston pin for wear or corrosion.

g) If the piston pin is a slack fit in an otherwise

serviceable piston, the piston bore and connecting

rod bushing can be reamed to take an oversize

piston pin. Refer the specifications for dimensions.

h) Insert piston ring in bore and use a piston without

ring to it square in the bore. Check the ring gap

(Fig. 7).

i) Repeat operation (h) with each piston ring and

reject anywhere the gap exceeds. (0.030 inch).

j) Check new rings in the same manner, as detailed

in operation (h) and check the gap to

specifications. The ends of the ring may be filled

carefully to bring the gap within the limits.

k) Check the clearance between the connecting rod

bearings and the crankshaft as follows :-

NOTE: Do not rotate the crankshaft while this check

is being made.

1) Assemble the insert to the connecting rods

and caps.

2) Lay a length of plastigauge across the

bearing cap insert.

3) Install the connecting rod on the crankshaft

all the main rod and tighten bolts to the

correct torque.

4) Remove each bearing cap and measure

thickness of the plastigauge to determine

the bearing clearance.

Remove the connecting rod from the

crankshaft.

Connecting Rods, Pistons & Cylinder Sleeves

Loading...

Loading...