8 ENGLISH

Function Status of the tool Status of the LED indicator/beeper Action to be taken

LED indicator Beeper

Alarm for low battery

capacity

The battery power

became low and it is

time to replace the

battery cartridge.

Flickers in red slowly. A series of long beeps Replace the battery with

fully charged one.

Auto-stop with low

remaining battery

capacity

The battery power is

almost used up and the

tool stopped.

Lights up in red. A long beep Replace the battery with

fully charged one.

Anti-reset of controller The battery voltage

dropped abnormally for

some reason, and the

tool stopped.

Flickers in red and green

alternatively.

A series of short beeps Replace the battery with

fully charged one.

Overheat protection Tool's controller heated

up abnormally and the

tool stopped.

Flickers in red quickly. A series of short beeps Remove the battery car-

tridge immediately and

cool the tool down.

Motor failure detection Motor failure has been

detected. At this time,

tool does not work.

Flickers in red and green

alternatively.

A series of short beeps Ask your local Makita

Service Center for repair.

Maintenance alarm A maintenance time has

come according to your

preset number of screws

driven.

Flickers in yellow. – Reset the alarm with the

application software.

Alarm for unavailable

data communication

(with the tool in connec-

tion with PC)

Data cannot be

exchanged between the

tool and PC in spite of

the connection.

Flickers in yellow. – Restart the application

software and re-connect

the USB cable.

Indication that data com-

munication is available

(with the tool in connec-

tion with PC)

The tool is connected to

PC and data communi-

cation is available.

Flickers in green. – –

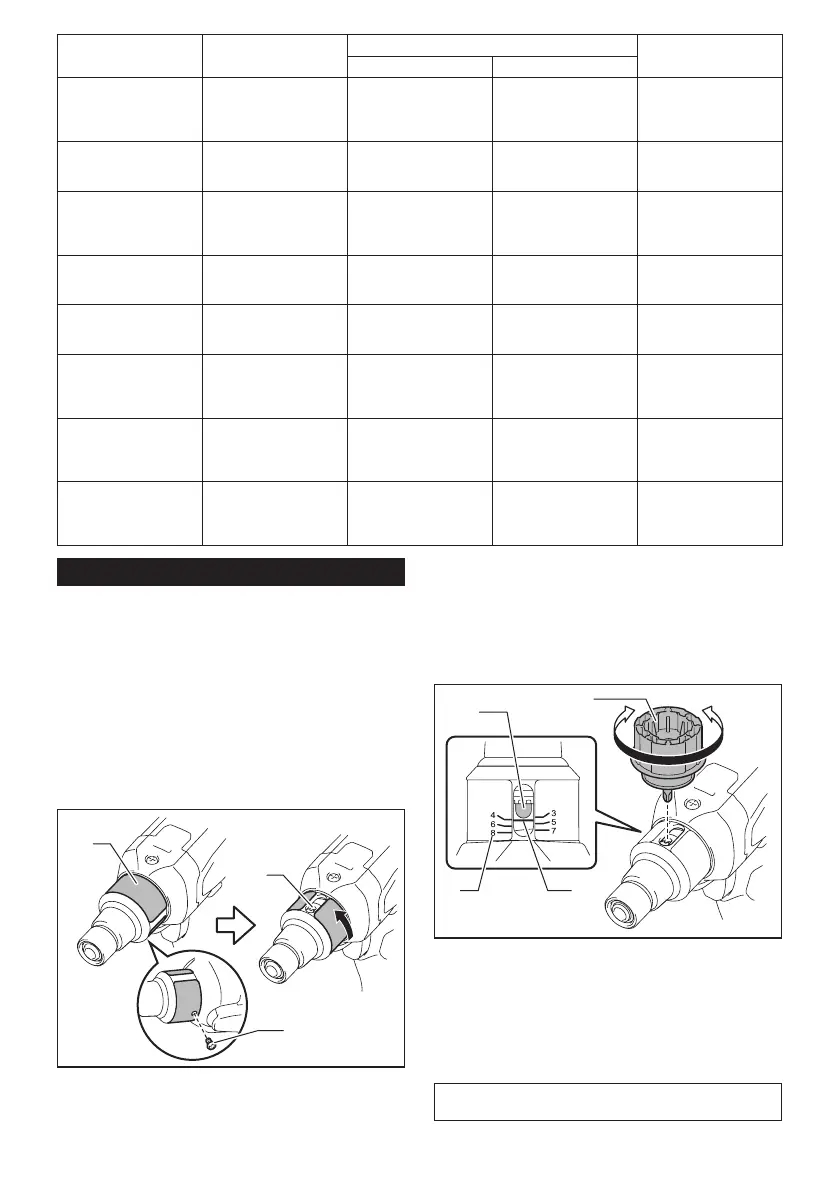

Adjusting the fastening torque

When you wish to drive machine screws, hex bolts,

etc. with the predetermined torque, adjust the fastening

torque as follows.

1. First remove the battery cartridge from the tool.

2. Loosen and remove the screw that secures ring.

3. Rotate the ring in the front of the tool by hand so

that a hole can be seen below the ring.

4. Install the battery cartridge in place. Pull the

switch trigger and release it so that the adjust ring

rotates and the hole becomes visible. And then remove

the battery cartridge.

3

1

2

►1. Ring 2. Screw 3. Hole

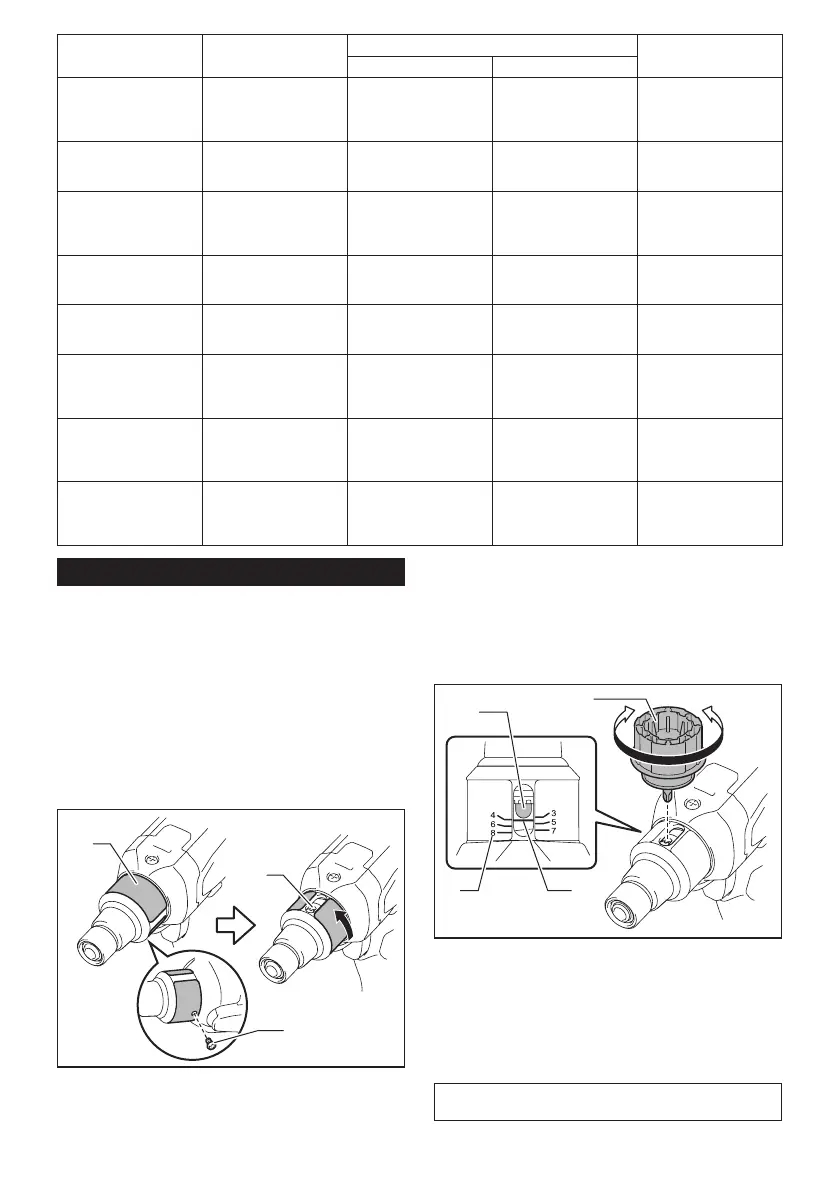

5. Use an optional adjust grip to adjust the fastening

torque. Insert the pin of the adjust grip into the hole

in the front of the tool. And then, turn the adjust grip

clockwise to set a greater fastening torque, and coun-

terclockwise to set a smaller fastening torque.

6. Align the yellow line with your desired number on

the fastening torque scale.

1

3

2

4

►1. Adjust grip 2. Hole for adjust grip 3. Scale

4. Yellow line

7. Insert the battery cartridge and be sure that a

fastening torque has been set up by using a fastening

torque tester.

8. Rotate the ring in front of the tool and then tighten

the screw to secure the ring.

NOTE: Numbers on the fastening torque scale is a

guideline to set up your desired fastening torque.

Loading...

Loading...