Checking and setting

45

Setting start of delivery

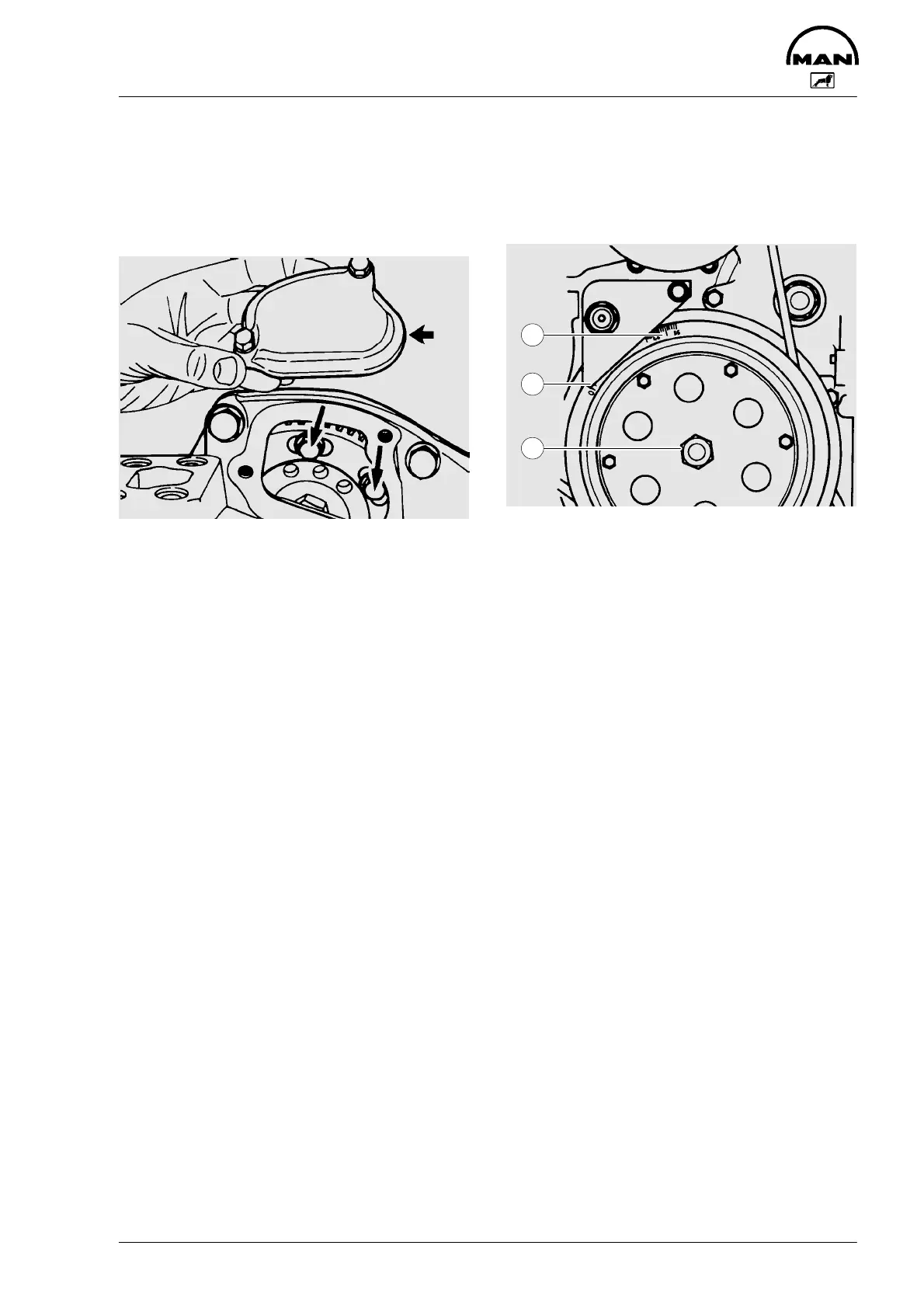

Correct start of delivery by turning the

pump hub in the slotted holes of the drive

gear.

Remove cover above the injection pump

drive gear

Rotate engine with barring device until the

pointer is on the specified start of delivery

(scale disc ahead of vibration damper).

Unscrew timing case cover. Remove fixing

screws of injection pump impeller. Turn

the hub of the injection pump accordingly

until the line marks (pointer and injection

pump hub) are in alignment. After every

adjustment carefully retighten fixing

screws.

Recheck start of delivery.

Use new gaskets when mounting cover

and screw plug.

Note:

The D 2866 LE / LXE engines with fan-

cooled radiator are not equipped with

a scale disc in front of the torsional

vibration damper. Start of delivery in

these engines should be set by means

of the degrees scale on the flywheel.

To check and set the start of deliv-

ery with start of delivery indicator

in the governor housing

(by authorized specialist personnel)

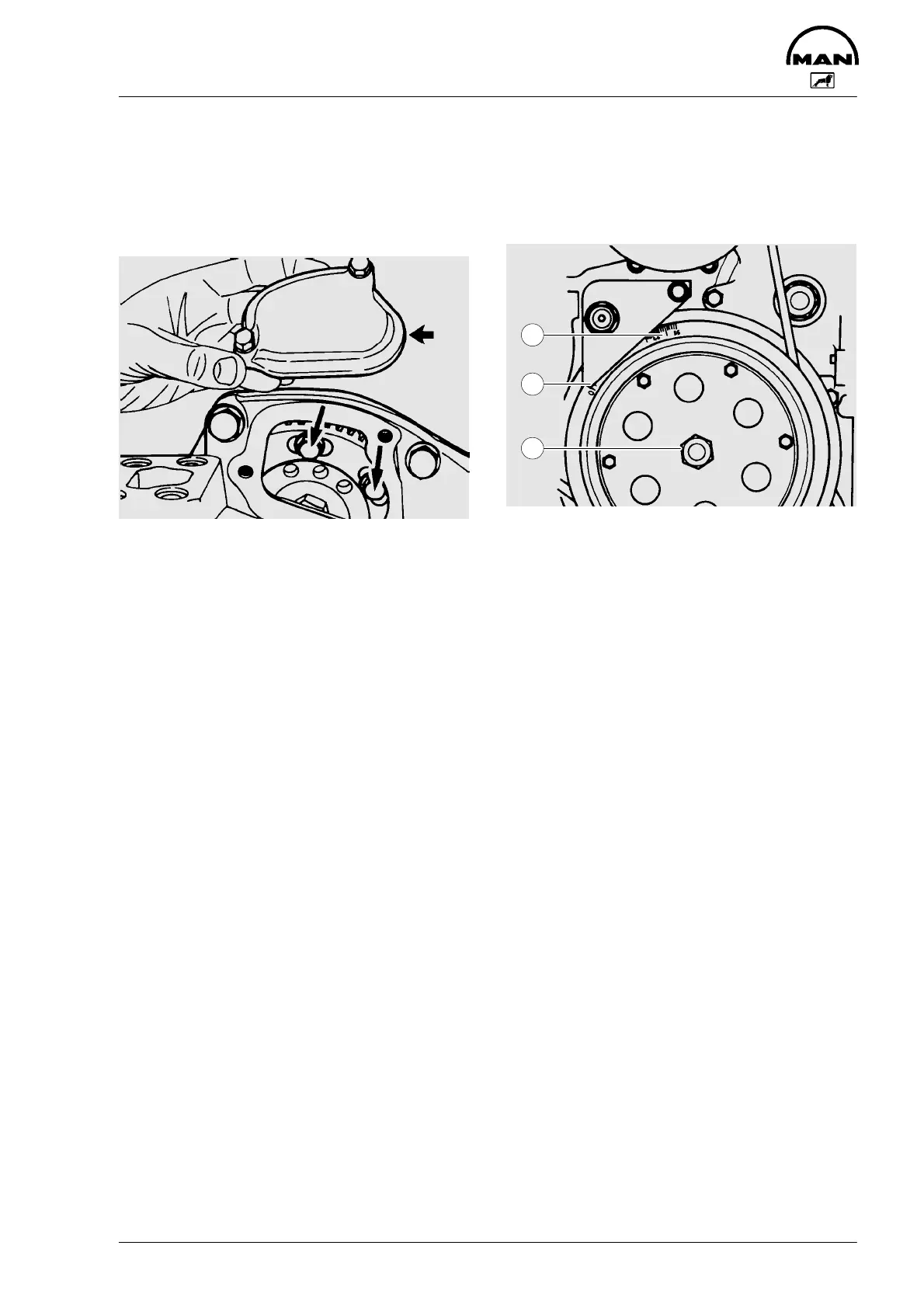

2

1

3

1 Setting pointer

2 “OT” (top dead centre) mark and scale

3 Hexagon driver to rotate engine by

hand (Width across flats 32)

For the purpose of checking the start-of-

delivery setting, an “OT” (top dead centre)

mark and a scale from 10 ... 50° before

top dead centre is engraved on a disc

fitted in front of the torsional vibration

damper. The scale marks are read against

a pointer fitted to the crankcase.

There is another scale engraved on the

flywheel which can be read through an in-

spection hole in the flywheel housing but

access may be difficult. The scale should

be used for readjusting the pointer after

the vibration damper has been removed

or replaced.

In other words, before the vibration

damper with the scale disc is installed, the

engine should be positioned at “OT” (top

dead centre) by means of the scale on the

flywheel.

Loading...

Loading...