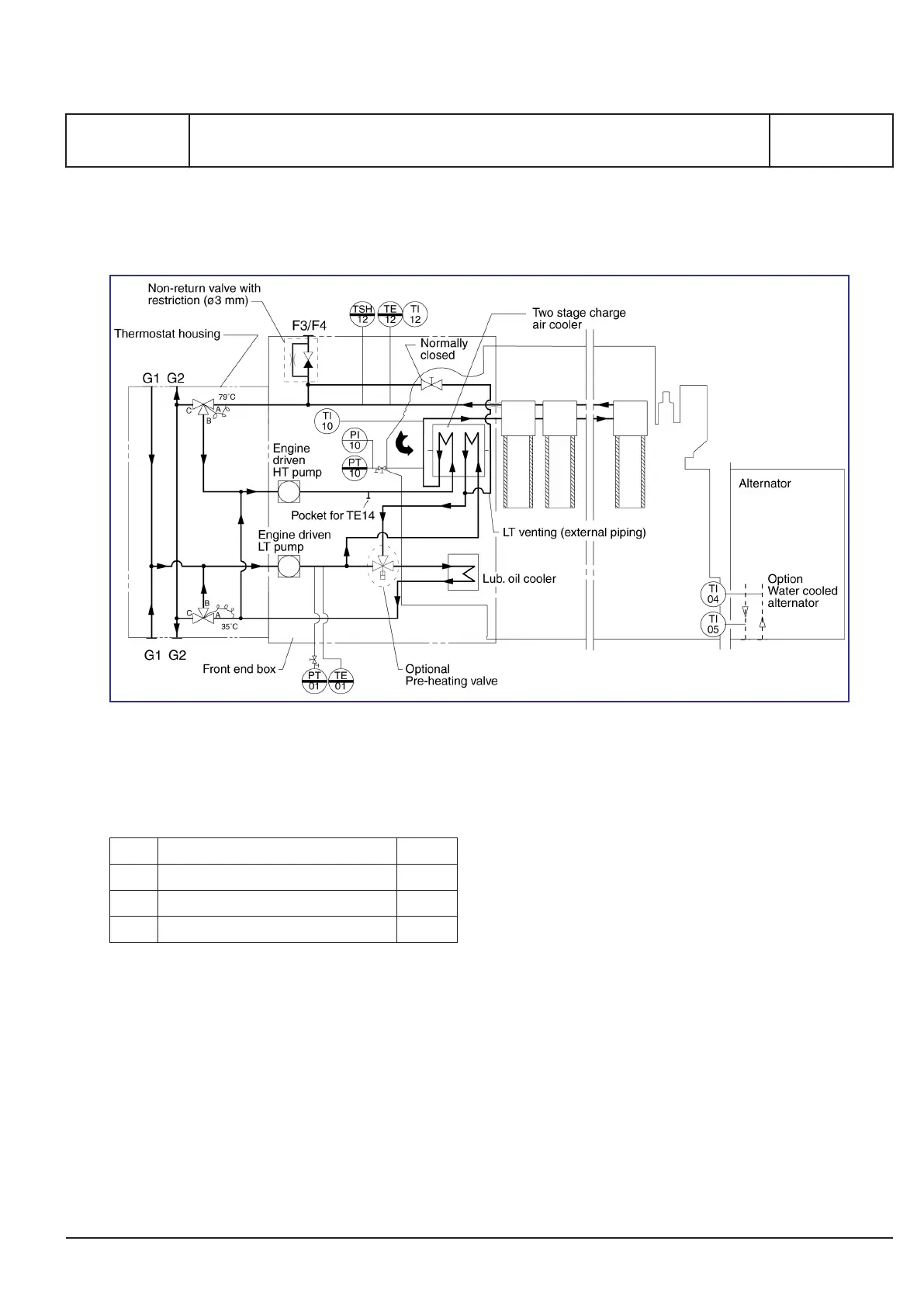

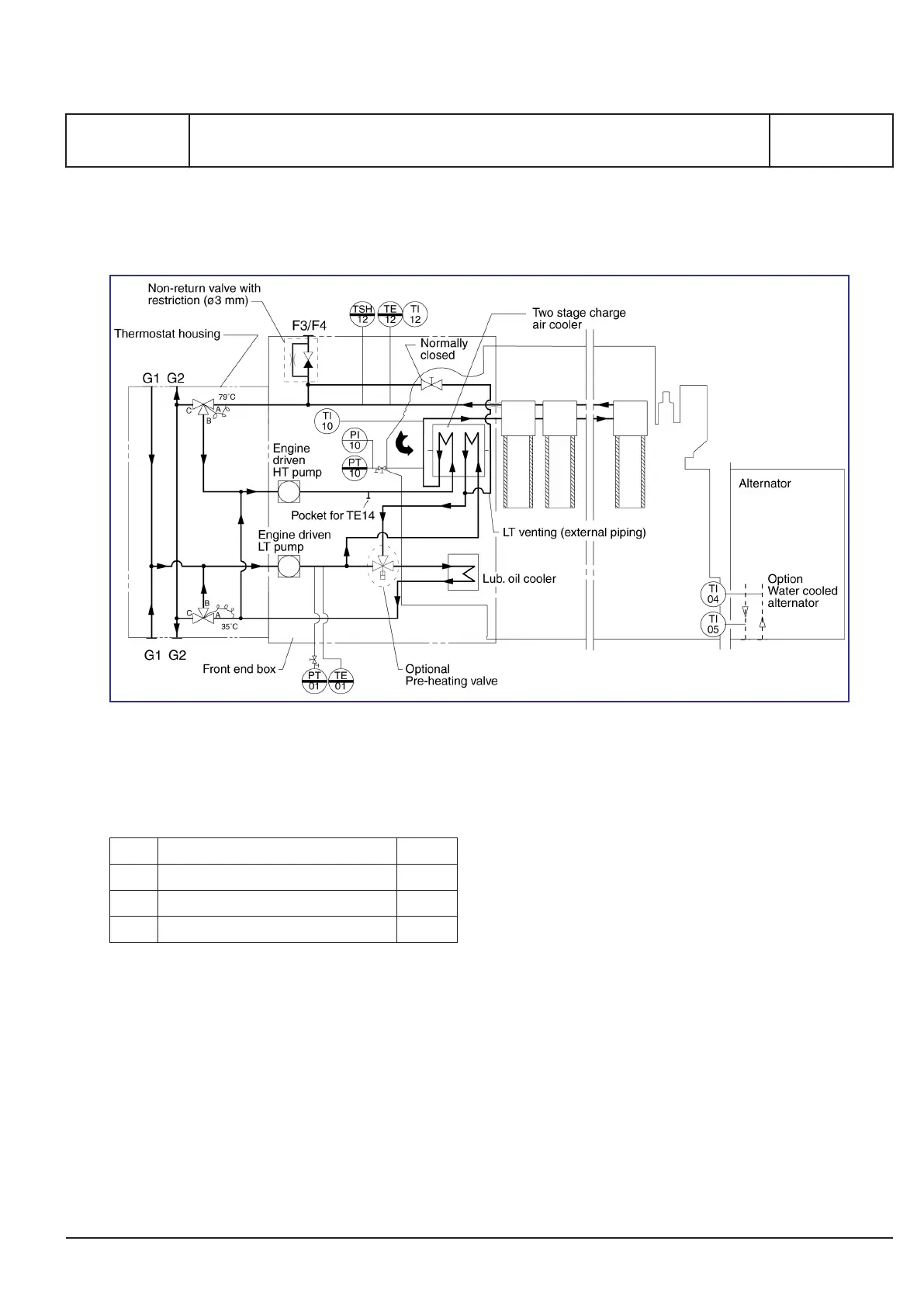

Internal cooling water system

Figure 1: Diagram for internal cooling water system (for guidance only, please see the plant specific engine diagram)

Pipe description

F3 Venting to expansion tank DN 25

F4 HT fresh water for preheating DN 25

G1 LT fresh water inlet DN 100

G2 LT fresh water outlet DN 100

Table 1: Flange connections are standard according to DIN 2501

Description

The system is designed as a single circuit with only

two flange connections to the external centralized

cooling water system.

The engine is equipped with a self-controlling tem-

perature water circuit.Thus, the engine on the cool-

ing water side only requires fresh water between 10

and 40°C and so the engine can be integrated in

the ship's cooling water system as a stand-alone

unit. This is a simple solution with low installation

costs, which also can be interesting in case of

repowering, where the engine power is increased,

and the distance to the other engines is larger.

Low temperature circuit

The components for circulation and temperature

regulation are placed in the internal system.

The charge air cooler and the lubricating oil cooler

are situated in serial order. After the LT water has

passed the lubricating oil cooler, it is let to the ther-

mostatic valve and depending on the water temper-

ature, the water will either be re-circulated or led to

the external system.

Preheating of charge air

Below approx. 40% load water is bypassed for LT-

side of charge air cooler and led directly to lub. oil

cooler. This is done to raise charge air temperature

and improve combustion. At the connection F3/F4

for the expansion tank there is a non-return valve

MAN Diesel & Turbo

3700201-8.0

Page 1 (2)

Internal cooling water system

B 13 00 3

L27/38S, L27/38

2015.04.23 - Tier II - one string

Loading...

Loading...