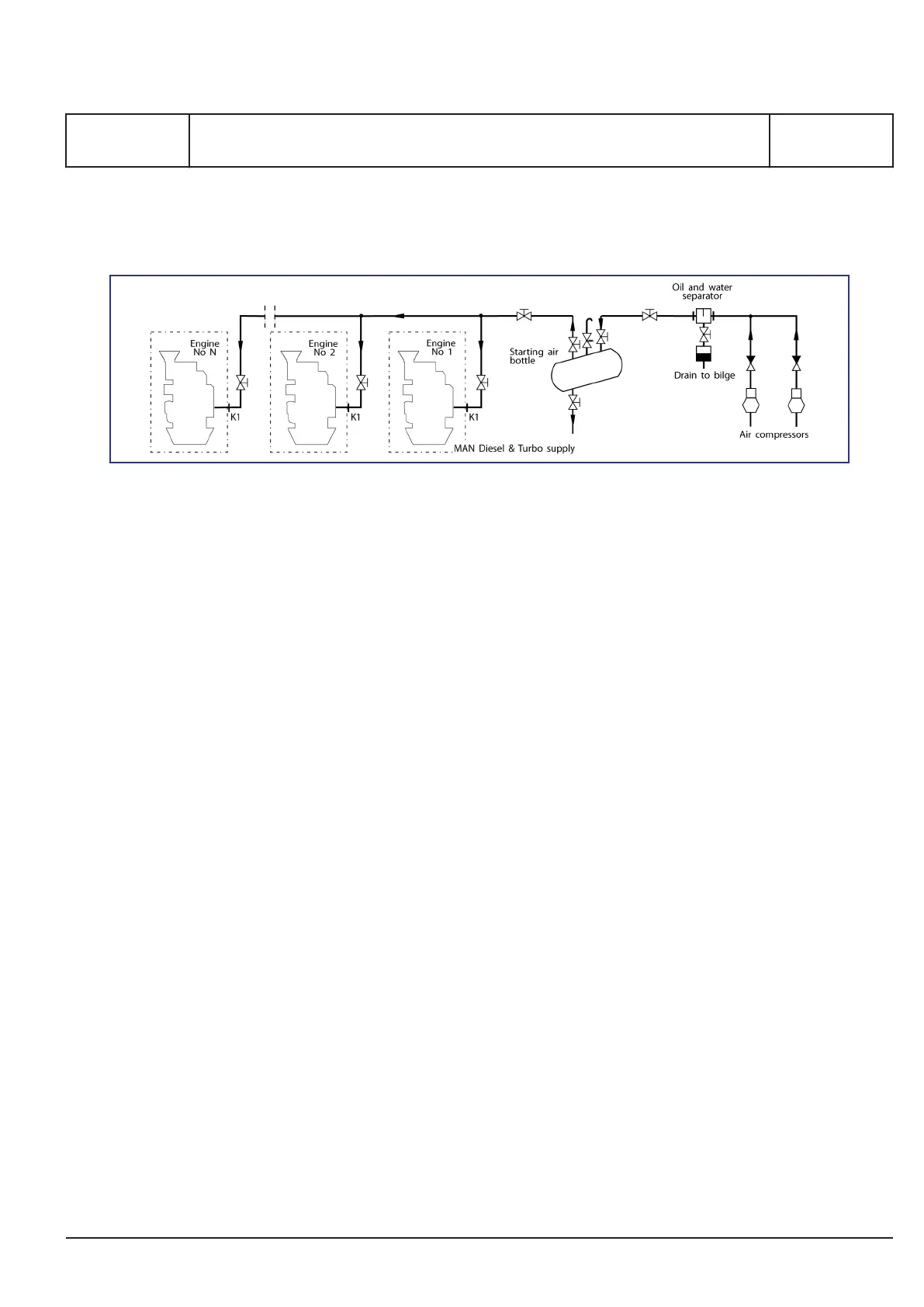

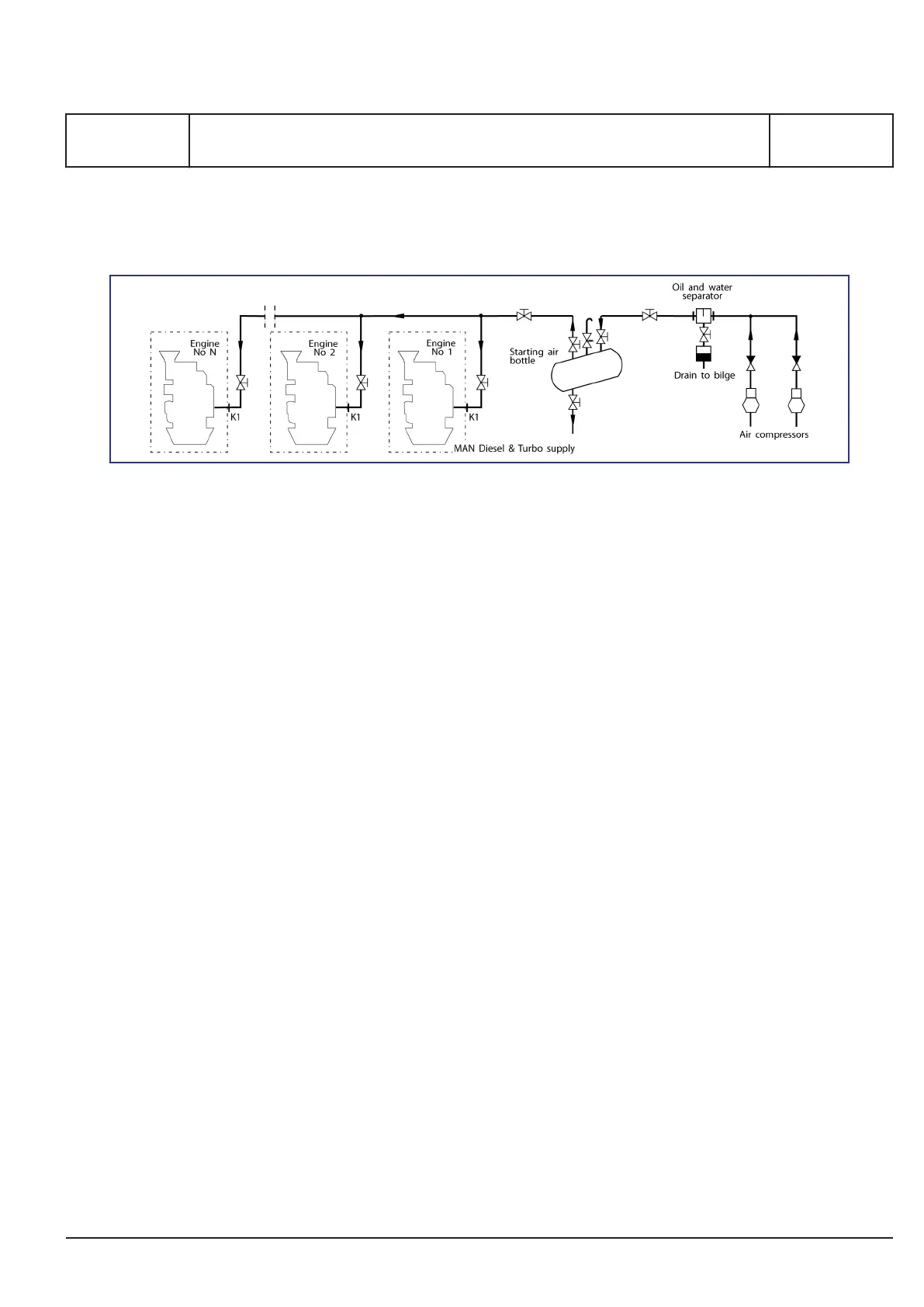

Diagram

Figure 1: Diagram for compressed air system

Design of external system

The external compressed air system should be

common for both propulsion engines and GenSet

engines.

Separate tanks shall only be installed in turbine ves-

sels, or if GenSets in engined vessels are installed

far away from the propulsion plant.

The design of the air system for the plant in ques-

tion should be according to the rules of the relevant

classification society.

As regards the engine's internal compressed air

system, please

see B 14 00 0 "Internal Com-

pressed Air System".

An oil and water separator should be mounted

between the compressor and the air receivers, and

the separator should be equipped with automatic

drain facilities.

Each engine needs only one connection for com-

pressed air, please

see diagram for the compressed

air system.

Installation

In order to protect the engine's starting and control

equipment against condensation water, the follow-

ing should be observed:

▪ The air receiver(s) should always be installed

with good drainage facilities. Receiver(s)

arranged in horizontal position must be installed

with a slope downwards of min. 3°-5°.

▪ Pipes and components should always be trea-

ted with rust inhibitors.

▪ The starting air pipes should be mounted with a

slope towards the receivers, preventing possi-

ble condensed water from running into the

compressors.

▪ Drain valves should be mounted at the lowest

position on the starting air pipes.

MAN Diesel & Turbo

1655207-3.2

Page 1 (1)

Compressed air system

B 14 00 0

L27/38S, L21/31S, L16/24S, L16/24, L21/31, L27/38

2015.11.27 - NG

Loading...

Loading...