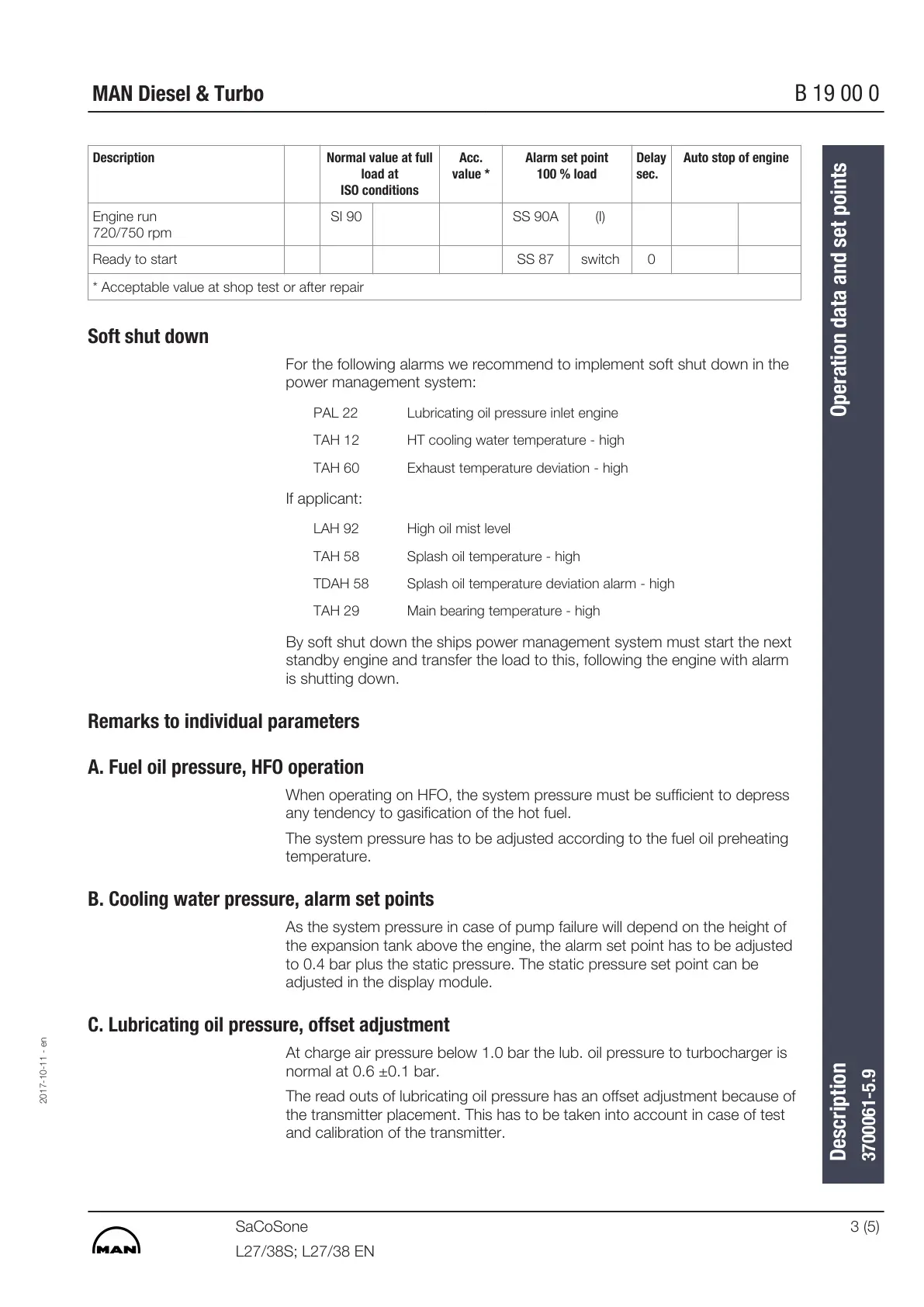

Description

Normal value at full

load at

ISO conditions

Acc.

value *

Alarm set point

100 % load

Delay

sec.

Auto stop of engine

Engine run

720/750 rpm

SI 90

SS 90A (I)

Ready to start

SS 87 switch 0

* Acceptable value at shop test or after repair

Soft shut down

For the following alarms we recommend to implement soft shut down in the

power management system:

PAL 22 Lubricating oil pressure inlet engine

TAH 12 HT cooling water temperature - high

TAH 60 Exhaust temperature deviation - high

If applicant:

LAH 92 High oil mist level

TAH 58 Splash oil temperature - high

TDAH 58 Splash oil temperature deviation alarm - high

TAH 29 Main bearing temperature - high

By soft shut down the ships power management system must start the next

standby engine and transfer the load to this, following the engine with alarm

is shutting down.

Remarks to individual parameters

A. Fuel oil pressure, HFO operation

When operating on HFO, the system pressure must be sufficient to depress

any tendency to gasification of the hot fuel.

The system pressure has to be adjusted according to the fuel oil preheating

temperature.

B. Cooling water pressure, alarm set points

As the system pressure in case of pump failure will depend on the height of

the expansion tank above the engine, the alarm set point has to be adjusted

to 0.4 bar plus the static pressure. The static pressure set point can be

adjusted in the display module.

C. Lubricating oil pressure, offset adjustment

At charge air pressure below 1.0 bar the lub. oil pressure to turbocharger is

normal at 0.6 ±0.1 bar.

The read outs of lubricating oil pressure has an offset adjustment because of

the transmitter placement. This has to be taken into account in case of test

and calibration of the transmitter.

2017-10-11 - en

Description

Operation data and set points

3700061-5.9

MAN Diesel & Turbo

B 19 00 0

SaCoSone

L27/38S; L27/38 EN

3 (5)

Loading...

Loading...