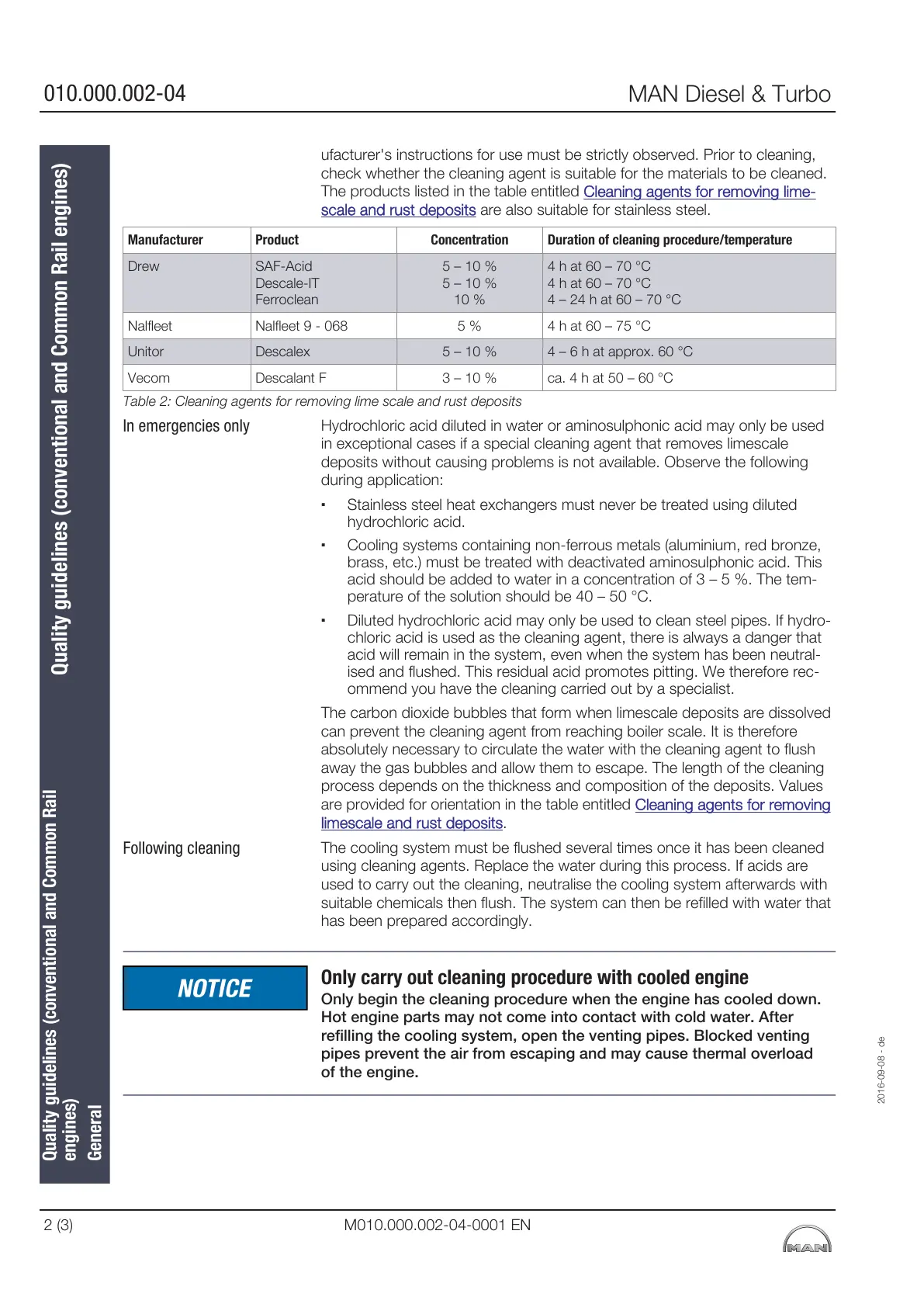

ufacturer's instructions for use must be strictly observed. Prior to cleaning,

check whether the cleaning agent is suitable for the materials to be cleaned.

The products listed in the table entitled Cleaning agents for removing lime-

scale and rust deposits are also suitable for stainless steel.

Manufacturer Product Concentration Duration of cleaning procedure/temperature

Drew SAF-Acid

Descale-IT

Ferroclean

5 – 10 %

5 – 10 %

10 %

4 h at 60 – 70 °C

4 h at 60 – 70 °C

4 – 24 h at 60 – 70 °C

Nalfleet Nalfleet 9 - 068 5 % 4 h at 60 – 75 °C

Unitor Descalex 5 – 10 % 4 – 6 h at approx. 60 °C

Vecom Descalant F 3 – 10 % ca. 4 h at 50 – 60 °C

Table 2: Cleaning agents for removing lime scale and rust deposits

Hydrochloric acid diluted in water or aminosulphonic acid may only be used

in exceptional cases if a special cleaning agent that removes limescale

deposits without causing problems is not available. Observe the following

during application:

▪ Stainless steel heat exchangers must never be treated using diluted

hydrochloric acid.

▪ Cooling systems containing non-ferrous metals (aluminium, red bronze,

brass, etc.) must be treated with deactivated aminosulphonic acid. This

acid should be added to water in a concentration of 3 – 5 %. The tem-

perature of the solution should be 40 – 50 °C.

▪ Diluted hydrochloric acid may only be used to clean steel pipes. If hydro-

chloric acid is used as the cleaning agent, there is always a danger that

acid will remain in the system, even when the system has been neutral-

ised and flushed. This residual acid promotes pitting. We therefore rec-

ommend you have the cleaning carried out by a specialist.

The carbon dioxide bubbles that form when limescale deposits are dissolved

can prevent the cleaning agent from reaching boiler scale. It is therefore

absolutely necessary to circulate the water with the cleaning agent to flush

away the gas bubbles and allow them to escape. The length of the cleaning

process depends on the thickness and composition of the deposits. Values

are provided for orientation in the table entitled

Cleaning agents for removing

limescale and rust deposits.

The cooling system must be flushed several times once it has been cleaned

using cleaning agents. Replace the water during this process. If acids are

used to carry out the cleaning, neutralise the cooling system afterwards with

suitable chemicals then flush. The system can then be refilled with water that

has been prepared accordingly.

Only carry out cleaning procedure with cooled engine

Only begin the cleaning procedure when the engine has cooled down.

Hot engine parts may not come into contact with cold water. After

refilling the cooling system, open the venting pipes. Blocked venting

pipes prevent the air from escaping and may cause thermal overload

of the engine.

In emergencies only

Following cleaning

Quality guidelines (conventional and Common Rail

engines)

Quality guidelines (conventional and Common Rail engines)

General

2016-09-08 - de

010.000.002-04

MAN Diesel & Turbo

2 (3) M010.000.002-04-0001 EN

Loading...

Loading...