led after the service tank, the supply pumps will

have to handle the pressure drop across the

MDO/MGO cooler which cannot be recommended.

The cooling medium used for the MDO/MGO cooler

is preferably fresh water from the central cooling

water system.

Seawater can be used as an alternative to fresh

water, but the possible risk of MDO/MGO leaking

into the sea water and the related pollution of the

ocean, must be supervised.

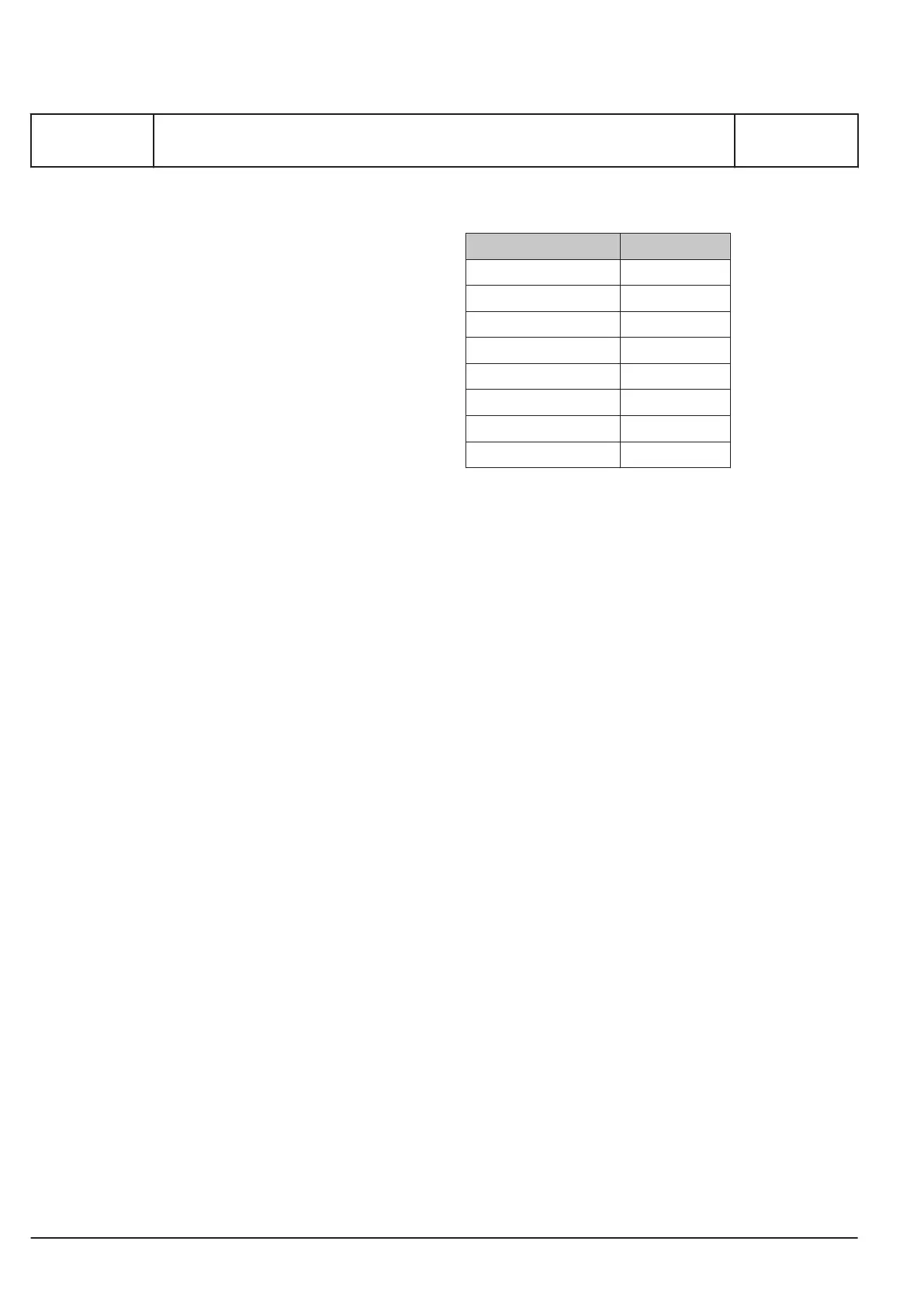

The horizontal axis shows the bunkered fuel viscos-

ity in cSt at 40°C, which should be informed in the

bunker analysis report.

If the temperature of the MGO is below the upper

blue curve at engine inlet, the viscosity is above 2.0

cSt. The black thick line shows the viscosity at ref-

erence condition (40°C) according to ISO8217,

marine distillates.

Example: MGO with viscosity of 4.0 cSt at 40°C

must have a temperature below 55°C at engine inlet

to ensure a viscosity above 3.0 cSt.

Example: MGO with a viscosity of 5.0 cSt at 40°C is

entering the engine at 50°C. The green curves

show that the fuel enters the engine at approxi-

mately 4.0 cSt.

Example: MGO with a viscosity of 2.0 cSt at 40°C

needs cooling to 18°C to reach 3.0 cSt.

The following items should be considered before

specifying the MDO/MGO cooler :

▪ The flow on the fuel oil side should be the same

as the capacity of the fuel oil circulating pump

( see D 10 05 0, List of Capacities )

▪ The fuel temperature to the MDO/MGO cooler

depends on the temperature of the fuel in the

service tank and the temperature of return oil

from the engine(s)

▪ The temperature of the cooling medium inlet to

the MDO/MGO cooler depends on the desired

fuel temperature to keep a minimum viscosity of

2.0 cSt

▪ The flow of the cooling medium inlet to the

MDO/MGO cooler depends on the flow on the

fuel oil side and how much the fuel has to be

cooled

The frictional heat from the fuel injection pumps,

which has to be removed, appears from the table

below.

Engine type

kW/cyl.

L16/24 0.5

L21/31 1.0

L27/38 1.5

L32/40 2.0

L23/30H 0.75

L28/32H 1.0

L28/32DF 1.0

V28/32S 1.0

Based on the fuel oils available in the market as of

June 2009, with a viscosity ≥ 2.0 cSt at 40°C, a fuel

inlet temperature ≤ 40°C is expected to be sufficient

to achieve 2.0 cSt at engine inlet

(see fig 1).

In such case, the central cooling water / LT cooling

water (36°C) can be used as coolant.

For the lowest viscosity MGO´s and MDO´s, a water

cooled MGO/MGO cooler may not be enough to

sufficiently cool the fuel as the cooling water availa-

ble onboard is typically LT cooling water (36°C).

In such cases, it is recommended to install a so-

called “Chiller” that removes heat through vapour-

compression or an absorption refrigeration cycle

(see fig 2).

MAN Diesel & Turbo

E 11 06 1

MDO / MGO cooler

1689458-7.3

Page 2 (3)

L28/32S, L27/38S, L23/30DF, L23/30S, L16/24S, L21/31S, L28/32DF, V28/32H,

V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

2016.03.03

Loading...

Loading...