National Crane PUBLISHED 04-26-2019 CONTROL # 113-09 5-5

600E2 OPERATOR MANUAL LUBRICATION PROCEDURE AND CHARTS

Internal Cable Sheave Lubrication

The lubrication points on the sheaves are not equipped with

grease fittings (zerks) and will require a grease gun adapter

to accomplish the task.

Special Tools:

Nozzle or needle grease gun fitting:

• 0.25 inch (6.35 mm) diameter nozzle grease gun tip

(National P/N 955047).

• Contact the Manitowoc Crane Care to obtain this tip.

• Observation through the sheave case for the extend

sheaves and the hoist mount for retract

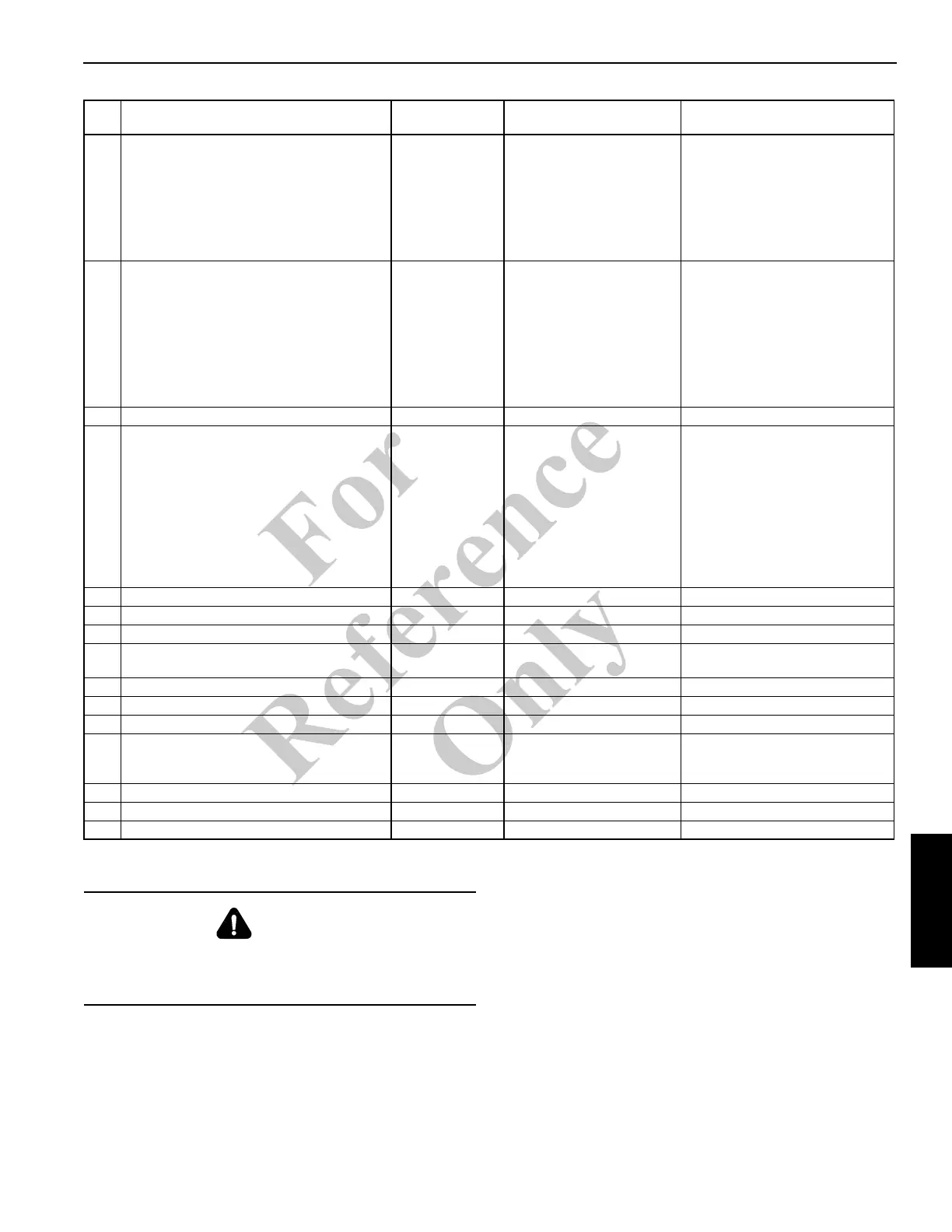

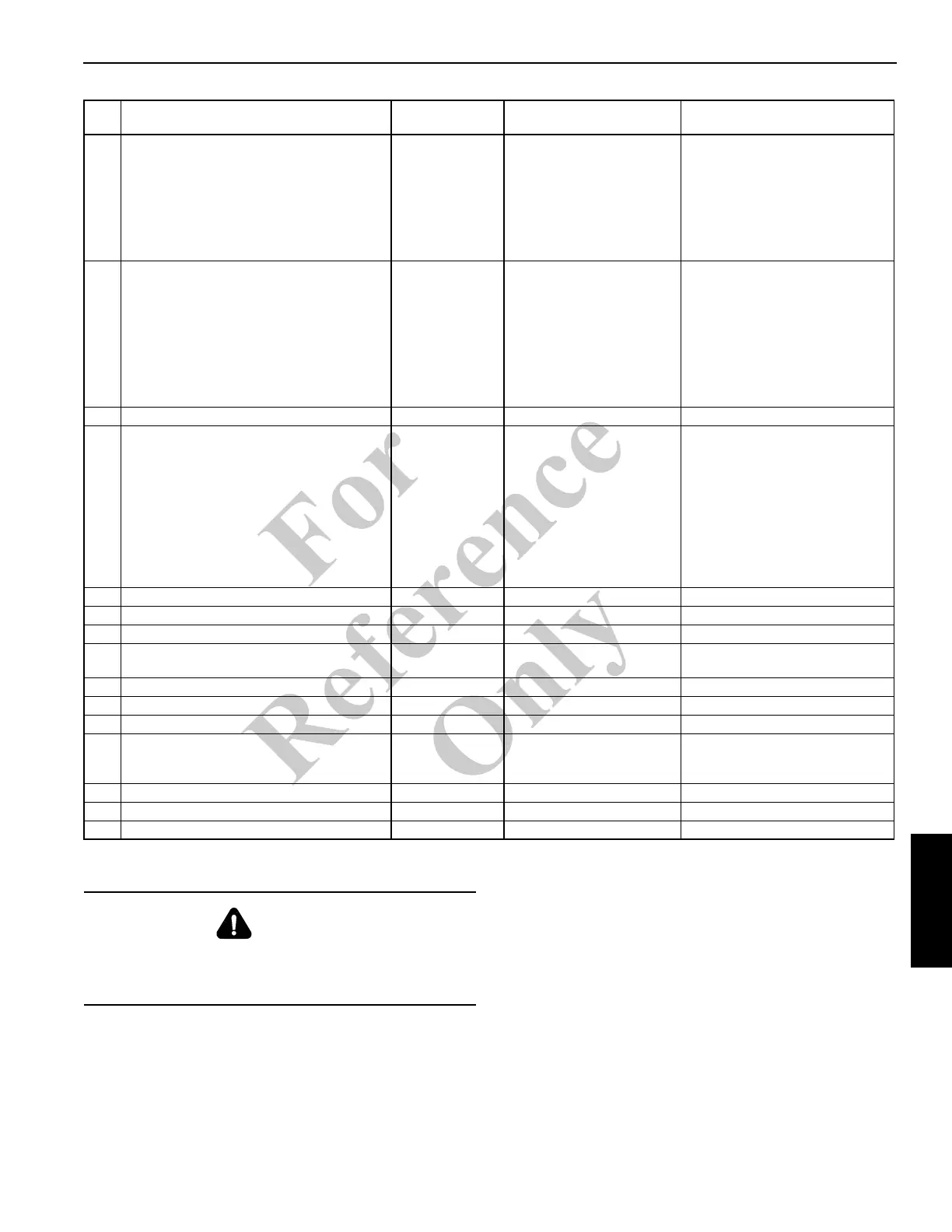

10a Hoist gearbox SAE 90 EP

Check and Fill

Change

Check and Fill: As part of daily crane

inspection, check the gearbox for

visible leaks.

Change: Every 1000 hours or

6months

10b Hoist brake HYDO

Check and Fill

Change

Check and Fill: As part of daily crane

inspection, check the gearbox for

visible leaks.

Change: Every 1000 hours or

6months

11 Control linkage EO-15W/40 Oil Can As Required

12 Swing drive gearbox GL-5

Check and Fill

Change

Check and Fill: As part of daily crane

inspection, check the gearbox for

visible leaks.

Change: After first 50 hours of

operation and every 500 hours

thereafter.

13 Swing gear teeth EP-OGL Spray Can Monthly

14 Boom extension LTG Brush, roller or grease gun Monthly or as required

15 Outrigger beams, bottom, sides LTG Brush or roller Monthly or as required

16 Extension cables (not shown) WRL Spray or brush

Any time boom is disassembled or

5 years

17 Boom Wear Pads (not shown) EP-MPG Brush or roller Monthly or as required

18 Swing Motor Pinion Bearing EP-MPG Grease gun Sparingly every 50 hours

19 Extend Sheaves EP-3MG Grease gun Weekly

20

Retract Sheaves: Extend the boom until the

retract sheave grease holes are visible through

the access holes along side of boom.

EP-3MG Grease gun Weekly

21 Diffuser strainer, Hydraulic oil reservoir Clean Semi-Annually with oil change

22 Magnetic plug, hydraulic oil reservoir Clean At oil filter service interval

23 Continuous rotation swivel (optional) EP-MPG Grease gun Monthly

Item Application

Recommended

Lubricant

Procedure Frequency

DANGER

Do not, under any circumstances, work at an elevated

height without using proper fall protection as required by

local, state or federal regulations

Fo

r

Reference

Only

Loading...

Loading...