4 21

When the battery is nearly drained, records will be lost or only maintained for a

short time and if this occurs the battery must be replaced. This battery is not user

replaceable and should only be replaced by qualified personnel.

To ensure maximum protection of instrument records they should be transferred

to a permanent copy on a daily basis.

Do not use the PAT as the primary store for your records.

WARNING: This product contains a lithium battery which must not be cut open,

incinerated, exposed to temperatures above +60ºC or recharged. “Dispose of in

accordance with local regulations”.

1. INTRODUCTION

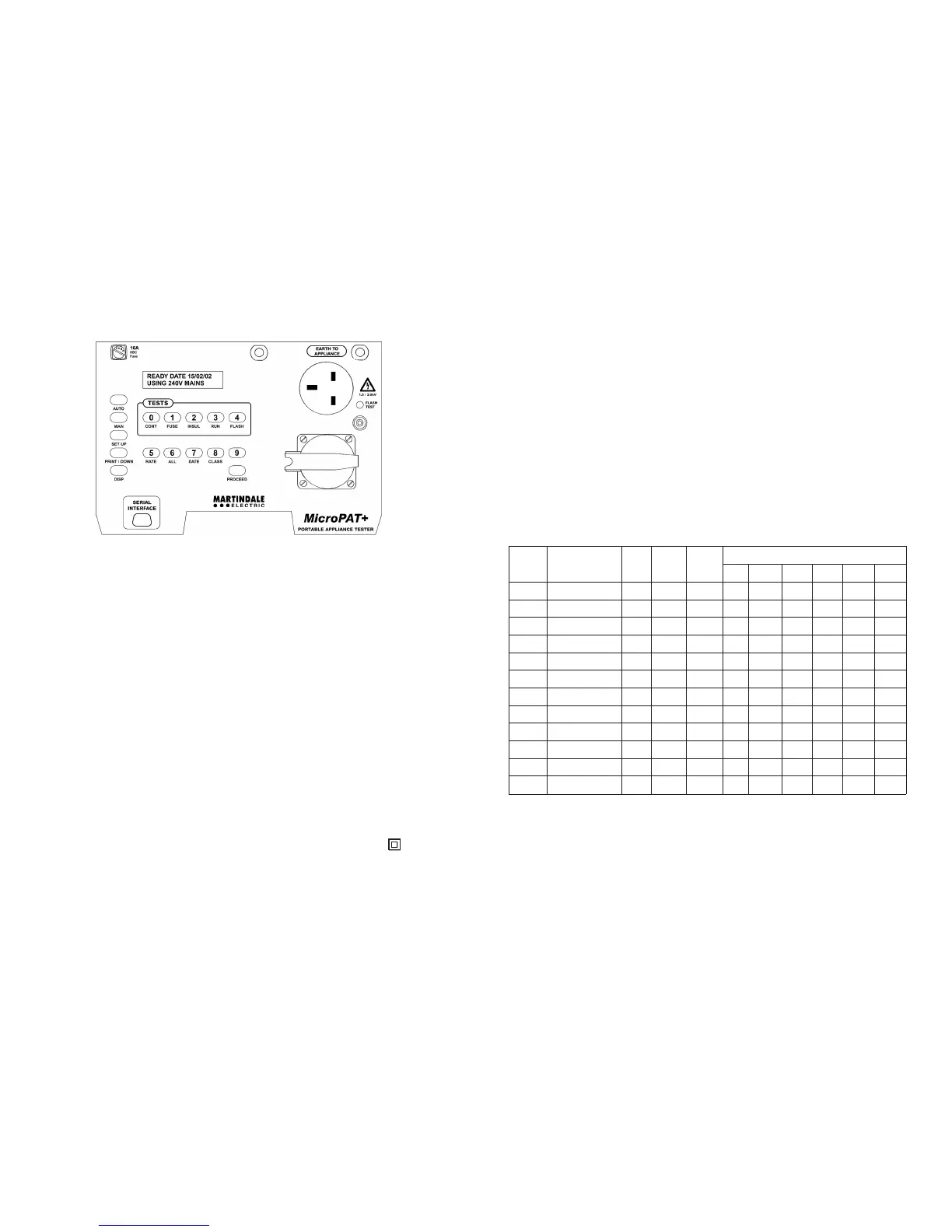

Fig. 1

1.1 Description

The MicroPAT+ microprocessor controlled Appliance Tester (Fig. 1) is housed in

a robust injection moulded case with a hinged lid. The base of the case contains

the complete power and electronics circuitry under the control panel. A sixteen

key tactile membrane switch pad with added audio feedback operates the tester.

Test leads and a comprehensive instruction manual are stored in the lid behind a

shelf which carries basic operating instructions.

The MicroPAT+ can scan Bar Code labels of the Appliance I.D. and Test

Parameters using an optional bar code reader. The Bar Code symbology used is

code 3 of 9 (USD-3). The bar code reader is connected to the serial interface

when required.

Tests carried out on both Class I and Class II electrical appliances are based on

the recommendations of the Electricity at Work Act, The Health & Safety

Executive and The Electronic & Business Equipment Association.

NOTE:

Class I - Earthed

Class II - Unearthed (double insulated), usually denoted by the symbol .

The MicroPAT+ can accept either 230/240V or 110V (55-0-55) 50/60Hz supplies

(via a special lead adaptor). A 240V and a 110V socket on the control panel

enables appliances of either voltage to be tested with the relevant mains supply.

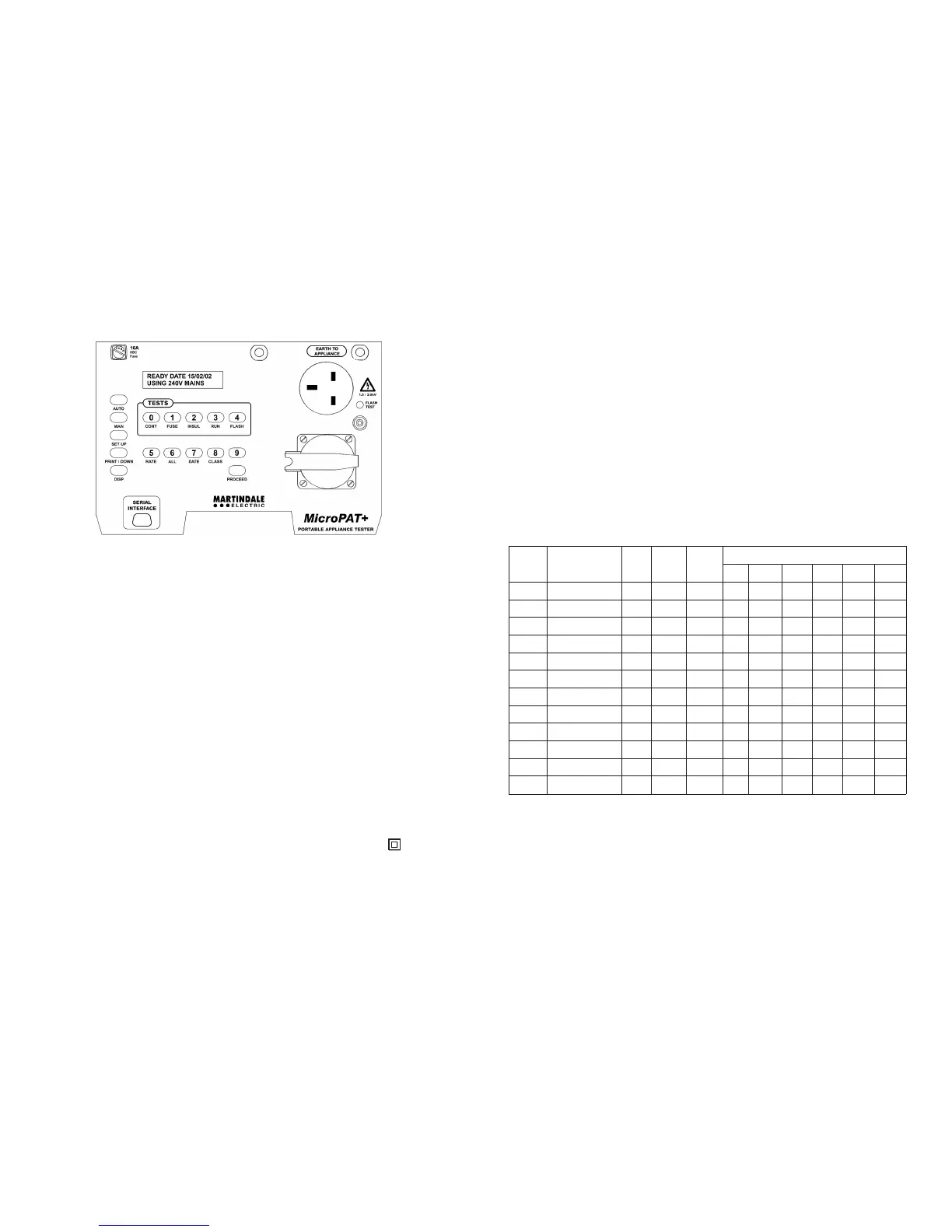

Six tests can be performed on an appliance whose mains switch should be ON.

Class Insulation Test Run Flash

Earth

Test

Test Codes

0.1Ω 0.2Ω 0.3Ω 0.4Ω 0.5Ω

I

Limit 1.0MΩ

Skip Skip 25A 01 02 03 04 05

I

Limit 1.0MΩ

Skip Test 25A 06 07 08 09 10

I

Limit 1.0MΩ

Test Skip 25A 11 12 13 14 15

I

Limit 1.0MΩ

Test Test 25A 16 17 18 19 20

I

Limit 1.0MΩ

Skip Skip 100mA 21 22 23 24 25

I

Limit 1.0MΩ

Skip Test 100mA 26 27 28 29 30

I

Limit 1.0MΩ

Test Skip 100mA 31 32 33 34 35

I

Limit 1.0MΩ

Test Test 100mA 36 37 38 39 40

II

Limit 2.0MΩ

Skip Skip Skip 81

II

Limit 2.0MΩ

Skip Test Skip 82

II

Limit 2.0MΩ

Test Skip Skip 83

II

Limit 2.0MΩ

Test Test Skip 84

Limit

NOTE: Older test codes for previous versions of firmware will still work correctly. There is no

distinction between ‘As New’ and ‘In Service’ so insulation pass limits will be Class I at 1.0MΩ

and Class II at 2.0MΩ for all codes.

3.7 Table of Codes for Test Parameters For Firmware Versions 6.1 Onwards

Loading...

Loading...