Operating instructions for Cable Detector, article 37270766

Page 19 of 34

5.1.6

Locating

blockages

in non-

conductive

lines

Requirements:

The pipeline must be of non-conductive material (such as plastic).

The pipeline must not be electrically charged.

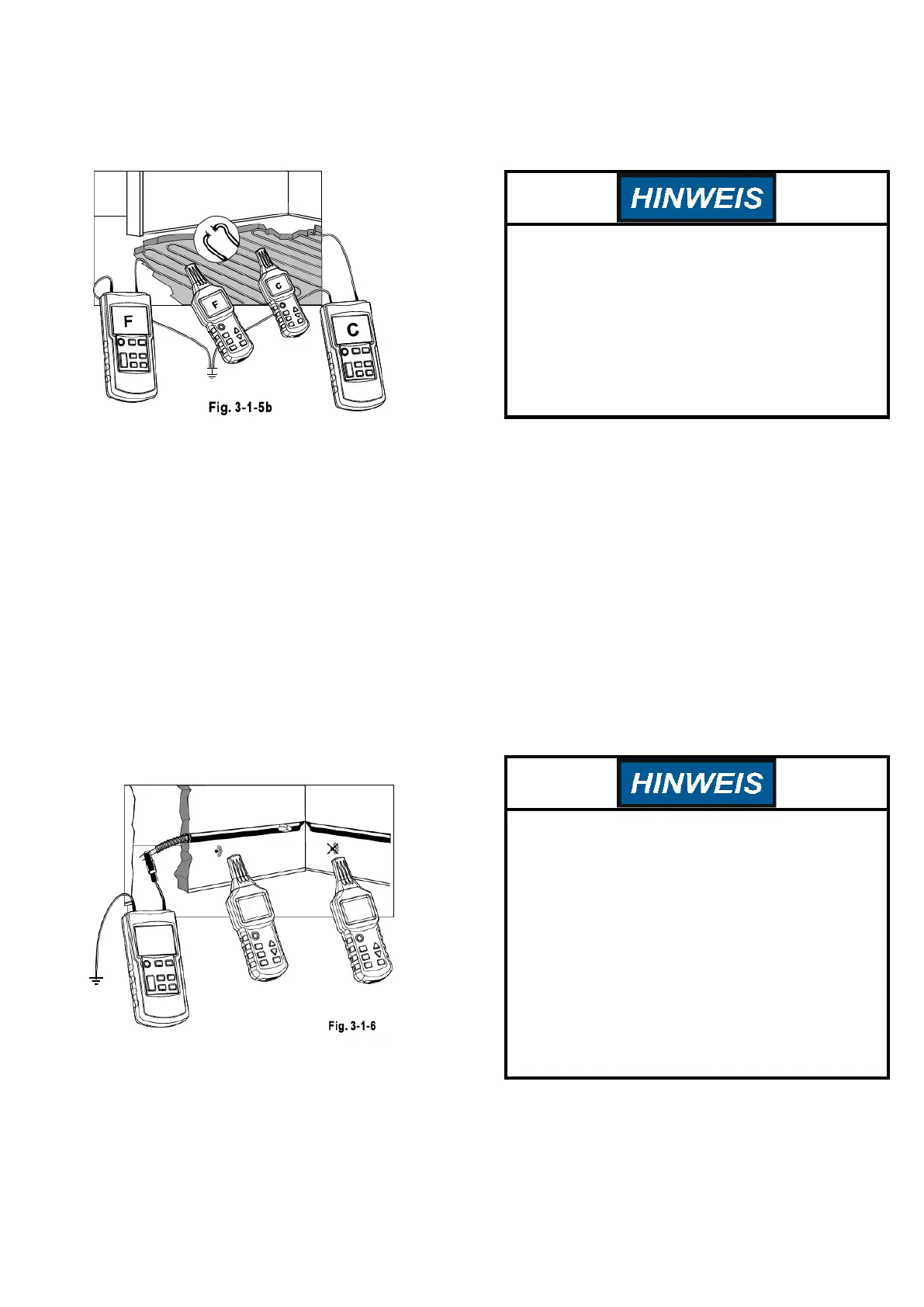

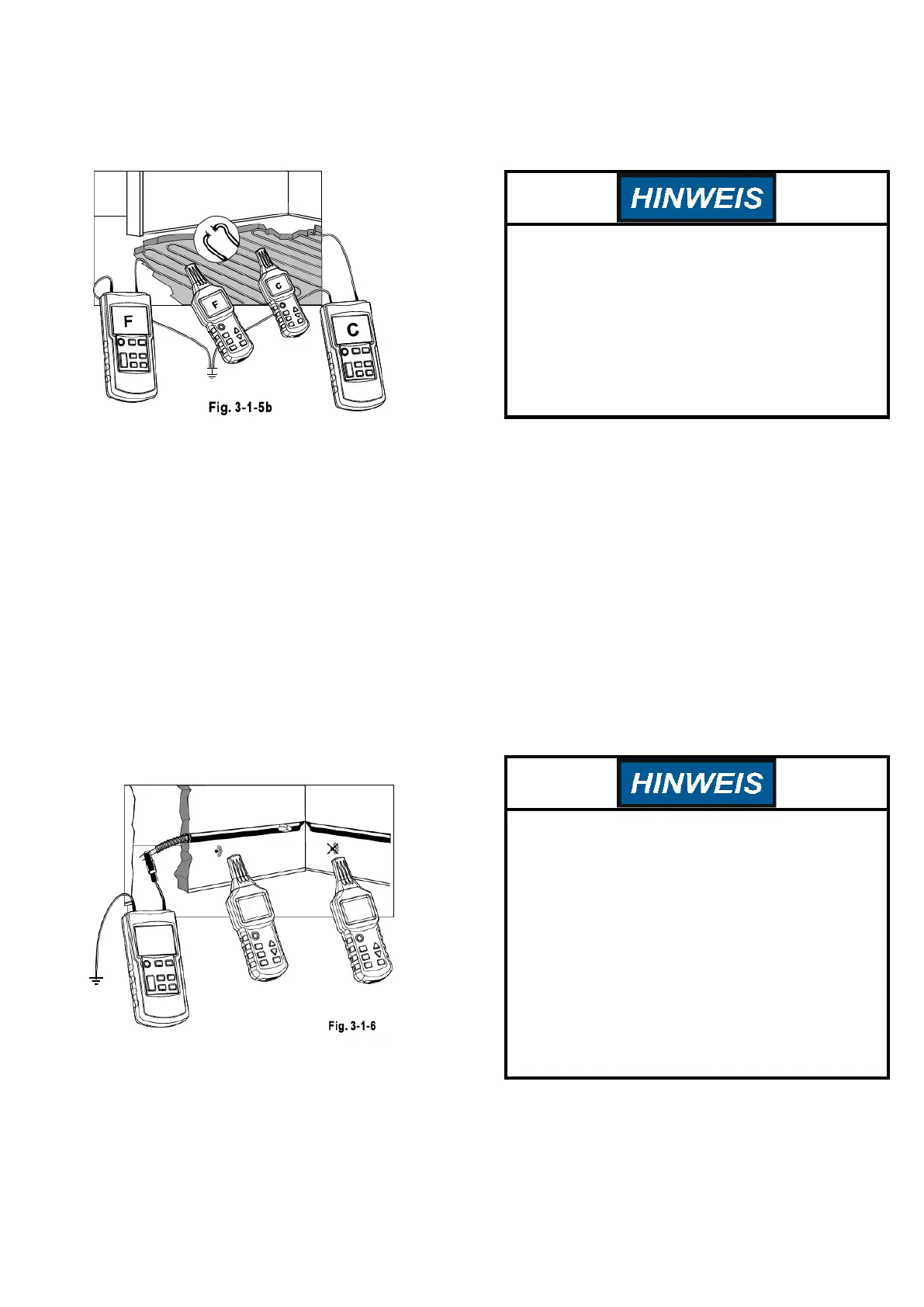

The transmitter must be connected to a metallic pipe coil (metallic pipe or flexible protective pipe) and an

auxiliary ground as shown in Fig. 3-1-6.

Use the measurement procedure as shown in the example.

1. If the pipeline is carrying electrical current, the current must be switched off and the pipeline must be

grounded.

2. Connect the grounding wire in accordance with applicable regulations. The transmitter should have enough

distance to the pipeline being measured. If the distance is too small, the signal and the modelled circuit

cannot be precisely located.

1. During tracking, at the break location there will be an

abrupt decline in the signal shown at the receiver.

2. Adjust the transmitter power to suit the different

search radii.

3. The position you are searching for can be detected

precisely by switching the receiver to manual mode

and setting the right sensitivity.

4. A second transmitter is not absolutely necessary for

this application. For using just one transmitter, see

Fig. 3-5-1a.

1. If you find only a pipeline made of non-conductive

material (like glass fibre), we recommend inserting a

metal wire with about 1.5 mm² cross-section into the

non-conductive pipe and to the narrow or blocked

section.

2. The stronger the signal shown on the receiver, the

closer the receiver is to the pipeline under test.

3. When the signals to the receiver suddenly get

weaker during testing along the pipeline, the

problem area has been found.

4. Adjust the transmitter power to suit the different

search radii. Set the receiver to manual mode and set

the right sensitivity to precisely locate the problem

area.

Loading...

Loading...